Gypsum pill, preparation method thereof and gypsum pill medicine pillow

A technology for gypsum pills and gypsum, which is applied in the field of preparation of gypsum pill pills and gypsum pills. It can solve the problems of poor plasticity, high hardness, and airtightness, and achieve good molding effect, good plasticity, and cervical spine protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The first aspect of the present invention provides a kind of preparation method of gypsum pellet, comprises the steps:

[0017] S1 Mix silica sol, crystal modifier, antibacterial and antifungal agent and water evenly to obtain auxiliary materials for the shell layer;

[0018] S2 provides the core layer material and the main material of the shell layer, and coats the shell layer material on the surface of the core layer material through hydration and condensation to obtain gypsum pellets. Wherein, the shell material is composed of the main material of the shell and the auxiliary material of the shell, and the main material of the shell includes gypsum powder.

[0019] In the present invention, by using gypsum powder as the main material of the shell layer to coat the surface of the lightweight core layer material and directly hydrating and coagulating, the problem of fast hydration and solidification of gypsum powder and difficult pilling is avoided, and the molding effe...

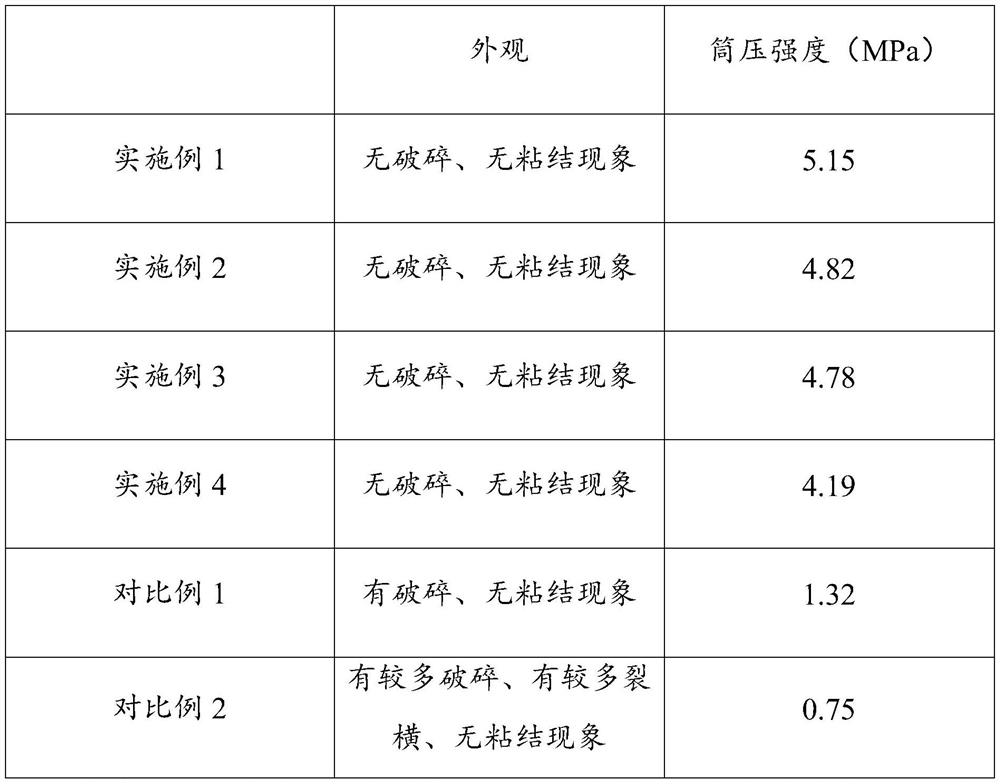

Embodiment 1

[0052] This embodiment provides a gypsum pill medicine pillow, which includes a pillow core filled with gypsum pills.

[0053] Gypsum pellets are specifically prepared through the following steps:

[0054] (1) Mix 0.9g silica sol, 0.04g crystal modifier, 0.06g antibacterial and antifungal agent and 10g water to obtain the auxiliary material of the shell;

[0055] (2) Provide 3g vitrified microspheres, 90gα gypsum powder and 80gβ gypsum powder, add the vitrified microspheres into the disc pelletizer, and spray the auxiliary material of the shell layer to wet the vitrified microspheres, then Add the pre-mixed α gypsum powder and β gypsum powder, and the mixed material will roll and rub under the joint action of gravity, centrifugal force and friction in the inclined and rotating disc, and last for 10-15 minutes until the shell material is in the glass. The hydration and coagulation on the surface of the chemical microbeads is carried out by chemical drying to obtain gypsum pellet...

Embodiment 2

[0057] This embodiment provides a gypsum pill medicine pillow, which includes a pillow core filled with gypsum pills.

[0058] Gypsum pellets are specifically prepared through the following steps:

[0059] (1) Mix 0.8g silica sol, 0.08g crystal modifier, 0.02g antibacterial and antifungal agent and 9g water to obtain the auxiliary material of the shell;

[0060] (2) Provide 3g closed-cell perlite, 100gβ gypsum powder and 25g rose pollen, add closed-cell perlite in the disc pelletizer, and use spraying to make the auxiliary material of the shell wet the closed-cell perlite, then Add the pre-mixed β gypsum powder and rose pollen, and the mixture will roll and rub under the joint action of gravity, centrifugal force and friction in the inclined and rotating disc, and last for 10-15 minutes until the shell material is in the closed cell. The surface of perlite is hydrated and condensed, and then dried to obtain gypsum pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com