Anion intercalation double-metal hydroxide adsorbent, preparation method and application thereof

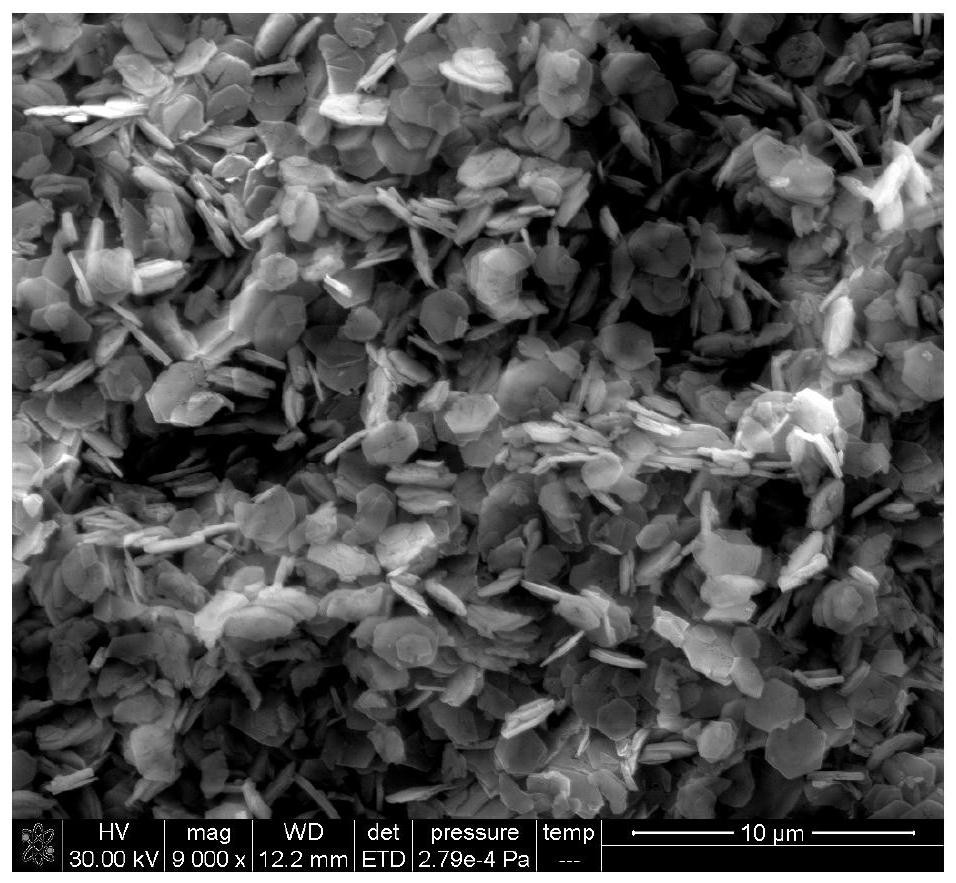

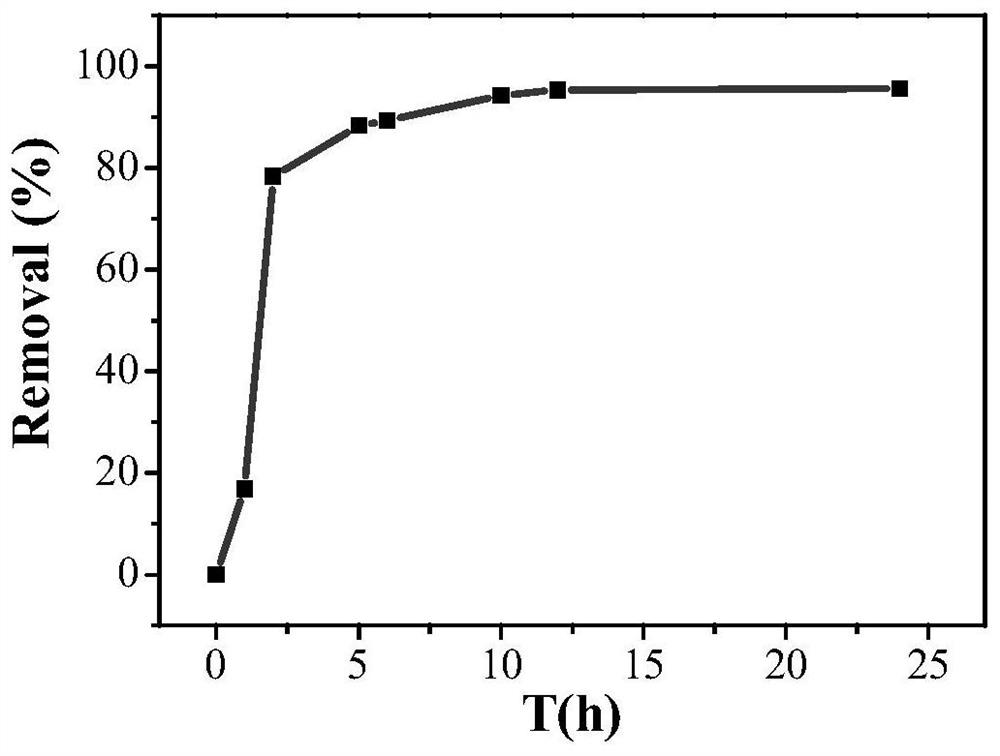

An anion intercalation, hydroxide technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problem of unstable crystal size of adsorbents, and achieve easy industrial production and popularization. , The effect of large grain size and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the double metal hydroxide adsorbent of anion intercalation comprises the following steps:

[0037] (1) Weigh 2.5642g soluble divalent metal magnesium salt magnesium nitrate and 1.6224g soluble trivalent metal aluminum salt aluminum nitrate, dissolve in 50mL deionized water to obtain mixed solution A;

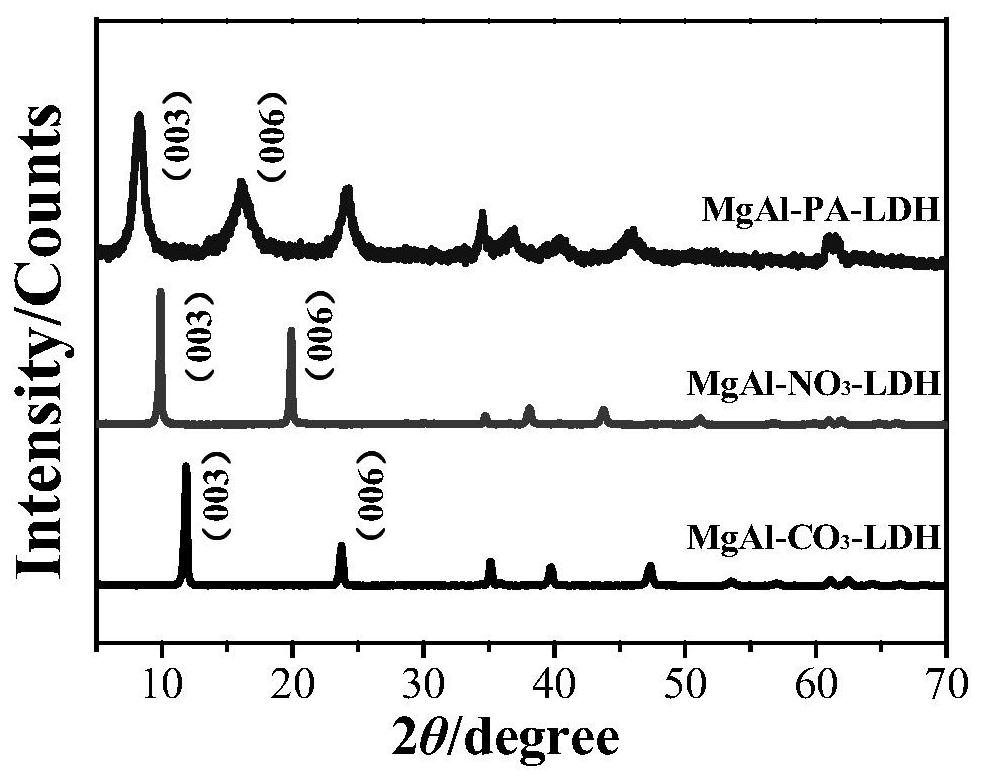

[0038] (2) Add urea to the mixed solution A in step (1), the molar ratio of urea to the trivalent metal aluminum salt added in step (1) is 1:1, stir evenly, transfer to polytetrafluoroethylene reaction In the kettle, the hydrothermal temperature is 100 ℃, and the hydrothermal time is 48 hours. The reaction is carried out under hydrothermal conditions, centrifuged, washed with deionized water, and dried in an oven. The sample obtained is the precursor MgAl-CO 3 -LDH;

[0039] (3) Weigh 0.1g of the precursor MgAl-CO in step (2) 3-LDH was dissolved in 50mL decarbonated deionized water, nitric acid and sodium nitrate were added, and the molar conc...

Embodiment 2

[0044] The preparation method of the double metal hydroxide adsorbent of anion intercalation comprises the following steps:

[0045] (1) Weigh 2.5642g soluble divalent metal magnesium salt magnesium nitrate and 1.8756g soluble trivalent metal aluminum salt aluminum nitrate, dissolve in 50mL deionized water to obtain mixed solution A;

[0046] (2) Add urea to the mixed solution A in step (1), the molar ratio of urea to the trivalent metal aluminum salt added in step (1) is 1:3, stir evenly, transfer to polytetrafluoroethylene reaction In the kettle, the hydrothermal temperature is 120 ℃, and the hydrothermal time is 36 hours for reaction under hydrothermal conditions, centrifuged, washed with deionized water, and dried in an oven. The sample obtained is the precursor MgAl-CO 3 -LDH;

[0047] (3) Weigh 0.1g of the precursor MgAl-CO in step (2) 3 -LDH was dissolved in 80mL decarbonated deionized water, nitric acid and sodium nitrate were added, and the molar concentration of so...

Embodiment 3

[0052] The preparation method of the double metal hydroxide adsorbent of anion intercalation comprises the following steps:

[0053] (1) Weigh 2.5642g soluble divalent metal magnesium salt magnesium nitrate and 1.6224g soluble trivalent metal aluminum salt aluminum nitrate, dissolve in 50mL deionized water to obtain mixed solution A;

[0054] (2) Add urea to the mixed solution A in step (1), the molar ratio of urea to the trivalent metal aluminum salt added in step (1) is 1:5, stir evenly, transfer to polytetrafluoroethylene reaction In the kettle, the hydrothermal temperature is 140 ° C, the hydrothermal time is 24 hours under hydrothermal conditions, centrifuged, washed with deionized water, and the sample obtained after drying in an oven is the precursor MgAl-CO 3 -LDH;

[0055] (3) Weigh 0.1g of the precursor MgAl-CO in step (2) 3 -LDH was dissolved in 100ml decarbonated deionized water, nitric acid and sodium nitrate were added, and the molar concentration of sodium nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com