A method for improving the bonding surface strength of copper tungsten and copper

A technology of copper bonding and copper-tungsten alloy, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of long production cycle and difficult control of tensile strength, and achieve the goal of simple method, shortening production cycle and improving tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

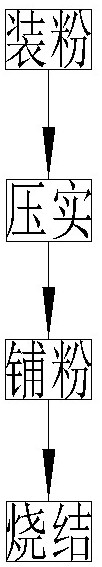

[0029] A method for improving the bonding surface strength of copper tungsten and copper, comprising the following steps:

[0030] S1: Load powder

[0031] Firstly, tungsten powder and copper powder are prepared into copper-tungsten composite powder according to 5% of the mass percentage of tungsten powder, and then the prepared composite powder is put into the graphite crucible for preparing copper-tungsten alloy;

[0032] The particle size of tungsten powder is 4-6μm, the oxygen content of tungsten powder is 0.025%; the copper powder is gas-atomized copper powder, the oxygen content of copper powder is 0.03%, and the particle size of copper powder is 3-5μm;

[0033] Before putting the copper-tungsten composite powder into the graphite crucible, spread a layer of graphite crucible paper on the bottom of the graphite crucible;

[0034] S2: Compaction

[0035] A stainless steel pressing plate is used to compact the copper-tungsten composite powder placed in the graphite cruci...

Embodiment 2

[0046] A method for improving the bonding surface strength of copper tungsten and copper, comprising the following steps:

[0047] S1: Load powder

[0048] First prepare tungsten powder and copper powder according to 50% of the mass percentage of tungsten powder to make copper-tungsten composite powder, and then put the prepared composite powder into the graphite crucible for preparing copper-tungsten alloy;

[0049] The particle size of tungsten powder is 4-6μm, the oxygen content of tungsten powder is 0.028%; the copper powder is gas-atomized copper powder, the oxygen content of copper powder is 0.04%, and the particle size of copper powder is 3-5μm;

[0050] Before putting the copper-tungsten composite powder into the graphite crucible, spread a layer of graphite crucible paper on the bottom of the graphite crucible;

[0051] S2: Compaction

[0052] A stainless steel pressing plate is used to compact the copper-tungsten composite powder placed in the graphite crucible, an...

Embodiment 3

[0063] A method for improving the bonding surface strength of copper tungsten and copper, comprising the following steps:

[0064] S1: Load powder

[0065] First prepare tungsten powder and copper powder according to 95% of the mass percentage of tungsten powder to make copper-tungsten composite powder, and then put the prepared composite powder into the graphite crucible for preparing copper-tungsten alloy;

[0066] The particle size of tungsten powder is 4-6μm, the oxygen content of tungsten powder is 0.29%; the copper powder is gas-atomized copper powder, the oxygen content of copper powder is 0.045%, and the particle size of copper powder is 3-5μm;

[0067] Before putting the copper-tungsten composite powder into the graphite crucible, spread a layer of graphite crucible paper on the bottom of the graphite crucible;

[0068] S2: Compaction

[0069] A stainless steel pressing plate is used to compact the copper-tungsten composite powder placed in the graphite crucible, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com