Preparation method and application of modified magnesium lithium silicate

A lithium magnesium silicate, modified technology, applied in chemical instruments and methods, silicon compounds, food science, etc., can solve problems such as poor absorption of mycotoxins, and achieve the effect of preventing mildew in feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

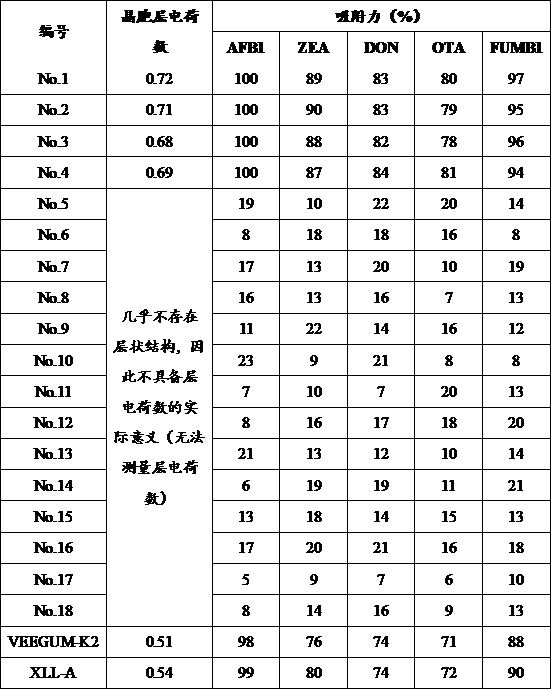

Image

Examples

Embodiment 1

[0019] A preparation method of modified lithium magnesium silicate, prepared according to the following steps from the following raw material components in parts by mass:

[0020] (1) First add 0.1 parts of beryllium chloride, 20 parts of magnesium chloride, 1 part of lithium chloride and 500 parts of pure water into the hydrothermal reaction kettle and stir thoroughly, then add sodium hydroxide solution with a mass fraction not exceeding 5% until The pH of the reaction system was 8.0, and then continued to fully stir for 10 minutes;

[0021] (2) Then add 1 part of boric acid and 30 parts of silica sol and stir thoroughly for 10 minutes, then heat up to 110°C in airtight conditions and keep it warm for 60 minutes;

[0022] (3) Next, stop the reaction and discharge the material, first filter the reaction solution and wash it thoroughly, and then roast the collected filter cake at 300°C for 10 minutes at high temperature to obtain the modified lithium magnesium silicate No.1.

Embodiment 2

[0024] A modified lithium magnesium silicate and a preparation method thereof, which are prepared from the following raw material components in parts by mass according to the following steps:

[0025](1) First, add 0.25 parts of beryllium sulfate, 0.25 parts of beryllium nitrate, 25 parts of magnesium sulfate, 25 parts of magnesium nitrate, 2.5 parts of lithium sulfate, 2.5 parts of lithium nitrate and 500 parts of pure water into the hydrothermal reaction kettle and fully stir, Then add a sodium hydroxide solution with a mass fraction of no more than 5% until the pH of the reaction system is 12.0, and then continue to fully stir for 30 minutes;

[0026] (2) Then add 5 parts of boric acid and 60 parts of silica sol and fully stir for 30 minutes, then heat up to 150°C in a sealed chamber and keep it warm for 120 minutes;

[0027] (3) Next, stop the reaction and discharge the material, first filter the reaction solution and wash it thoroughly, and then roast the collected filter...

Embodiment 3

[0029] A modified lithium magnesium silicate and a preparation method thereof, which are prepared from the following raw material components in parts by mass according to the following steps:

[0030] (1) First, 0.1 parts of beryllium chloride, 0.1 parts of beryllium sulfate, 0.1 parts of beryllium nitrate, 10 parts of magnesium chloride, 10 parts of magnesium sulfate, 10 parts of magnesium nitrate, 1 part of lithium sulfate, 1 part of lithium nitrate, and 1 part of lithium hydroxide And add 500 parts of pure water into the hydrothermal reaction kettle and fully stir, then add a sodium hydroxide solution with a mass fraction not exceeding 5% until the pH of the reaction system is 9.0, and then continue to fully stir for 15 minutes;

[0031] (2) Then add 2 parts of boric acid and 40 parts of silica sol and stir thoroughly for 15 minutes, then heat up to 120°C in airtight conditions and keep it warm for 80 minutes;

[0032] (3) Next, stop the reaction and discharge the material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com