Method for regulating and controlling short-cut nitrification-synchronous nitrification and denitrification sewage treatment process based on oxidation-reduction potential and application thereof

A technology of simultaneous nitrification and short-range nitrification, applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of short-range nitrification-simultaneous nitrification and denitrification process efficiency is not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

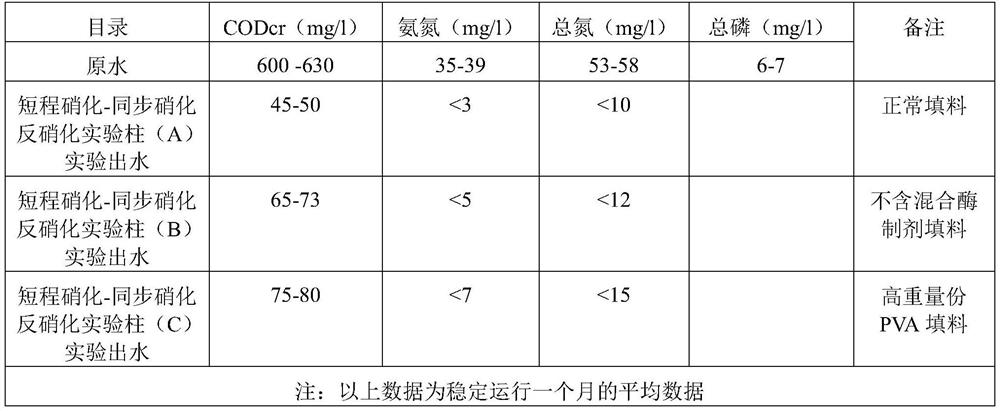

Examples

preparation example 1

[0033]In a sewage treatment facility, take 20 kg of activated sludge with a solid content of 5% from the short-cut nitrification process, and cultivate it with a high ammonia nitrogen solution with a prepared ammonia nitrogen concentration of 300 mg / L to make nitrosating bacteria and nitrifying bacteria Bacteria are multiplied and enriched. In the enriched reactor, the PH value is controlled to be 8.0-8.3, and the dissolved oxygen is 0.5-1.0, so that it is under the reaction conditions where nitrosifying bacteria are dominant, so as to obtain a product with a high proportion of nitrosifying bacteria and a low proportion of nitrifying bacteria. Nitrosifying bacteria and nitrifying bacteria enrichment mixture. After changing the water every day and cultivating for one month, the bacterial mixture was naturally precipitated three times, and the supernatant was removed to obtain nitrosating bacteria and nitrifying bacteria concentrates with a solid content of 5%.

[0034] Take by...

preparation example 2

[0037] In a sewage treatment facility, take 20 kg of activated sludge with a solid content of 5% from the short-cut nitrification process, and cultivate it with a high ammonia nitrogen solution with a prepared ammonia nitrogen concentration of 300 mg / L to make nitrosating bacteria and nitrifying bacteria Bacteria are multiplied and enriched. In the enriched reactor, the PH value is controlled to be 8.0-8.3, and the dissolved oxygen is 0.5-1.0, so that it is under the reaction conditions where nitrosifying bacteria are dominant, so as to obtain a product with a high proportion of nitrosifying bacteria and a low proportion of nitrifying bacteria. Nitrosifying bacteria and nitrifying bacteria enrichment mixture. After changing the water every day and cultivating for one month, the bacterial mixture was naturally precipitated three times, and the supernatant was removed to obtain nitrosating bacteria and nitrifying bacteria concentrates with a solid content of 5%.

[0038] Weigh ...

preparation example 3

[0045] Enrichment and concentration culture of denitrifying bacteria: in sewage treatment plant A 2 In the / O process, take the activated sludge from the anoxic pool, and use the prepared high nitrate nitrogen solution with a nitrate nitrogen concentration of 300mg / l to cultivate and domesticate it, so that the denitrifying bacteria can be multiplied and enriched. Dissolved oxygen is controlled at 0.3-0.5mg / l in the acclimatization and enrichment reactor, and sufficient carbon source is added to the acclimatization reactor, so that denitrifying bacteria can rapidly multiply and enrich. The acclimatized and enriched mixed solution undergoes 2-3 times of natural precipitation, and the supernatant is removed to obtain a concentrated solution of denitrifying bacteria with a solid content of 3%-5%.

[0046] According to the protocol in Preparation Example 1, the obtained concentrated bacterial solution containing the denitrifying bacteria was prepared to obtain the required active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com