Internal doping type concrete reinforcing agent and preparation method thereof

A technology of concrete reinforcing agent and internal mixing type, applied in the field of composite fiber materials, can solve the problems of poor adaptability, high cost, and difficulty in achieving the purpose of reinforcement, so as to promote full hydration, improve corrosion resistance, improve and efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A built-in concrete reinforcing agent, comprising the following raw material components in parts by mass: 80-90 parts of deionized water, 0.2-1.0 parts of potassium carbonate, 2-5 parts of calcium acrylate, 2-5 parts of mixed small materials, 0.01-0.05 parts of foaming agent; the mixed small material is a mixture of four small molecule alcohol amines, triethanolamine, diethanol monoisopropanolamine and triisopropanolamine in any proportion. The small molecule alcohol amines may be any one or more of monoethanolamine, monoisopropanolamine and diethanolamine.

[0024] In this embodiment, calcium acrylate can have good interfacial bonding with cement, and its addition can reduce the porosity of cement stone, optimize pore distribution, and improve the corrosion resistance of cement. Calcium acrylate forms a network structure in the cement stone, runs through the cement stone, and can form a good interface combination with the cement. It can fill the pores of cement stone ...

Embodiment 2

[0038]A built-in concrete reinforcing agent, the parts by mass of each component are: 0.5 parts of potassium carbonate, 3 parts of calcium acrylate, 3.0 parts of small mixing materials, 0.03 parts of defoaming agent, and 86.97 parts of deionized water. The small mixing material is a mixture composed of diethanolamine, triethanolamine, diethanol monoisopropanolamine and triisopropanolamine at a ratio of 0.8:2.5:2.5:1.5. The preparation process is to add deionized water, potassium carbonate, and calcium acrylate into the compound kettle according to the ratio of dosage at 20°C, and stir for 5 to 15 minutes to obtain a uniform solution; then add small molecule alcohol amines, triethanolamine, Add the mixed small material composed of diethanol monoisopropanolamine and triisopropanolamine into the compound kettle, and stir for 15-45 minutes to obtain the concrete reinforcing agent.

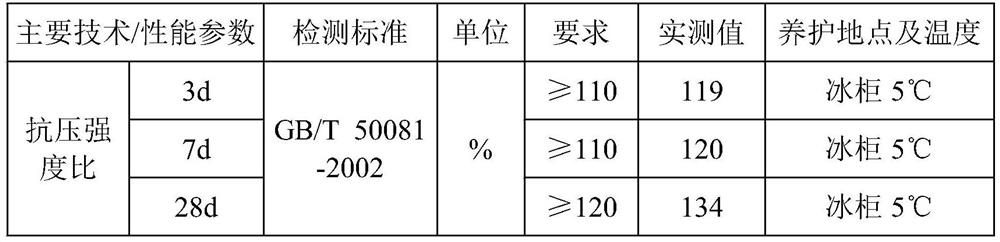

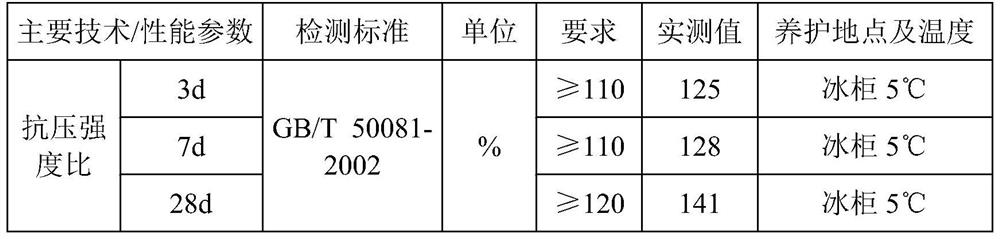

[0039] Concrete mix ratio: 280 Esheng cement + 80 national standard secondary fly ash + 865 machine...

Embodiment 3

[0045] A method for preparing a built-in concrete reinforcing agent, the mass percentage of each component is: 0.8 parts of potassium carbonate, 3 parts of calcium acrylate, 3.0 parts of ethylene glycol, 3.3 parts of 1,2-propylene glycol, mixing small 3.4 parts of material, 0.04 parts of defoamer, 86.46 parts of deionized water. The small mixing material is a mixture of monoethanolamine, triethanolamine, diethanol monoisopropanolamine and triisopropanolamine at the ratio of 1.0:2.6:2.6:1.8.

[0046] Concrete mix ratio: 280 Esheng cement + 80 national standard secondary fly ash + 865 machine-made sand + 1072 stone + 170 water.

[0047] The dosage of concrete reinforcing agent in concrete is 7.5kg / m 3 Concrete, and the use of equivalent replacement water.

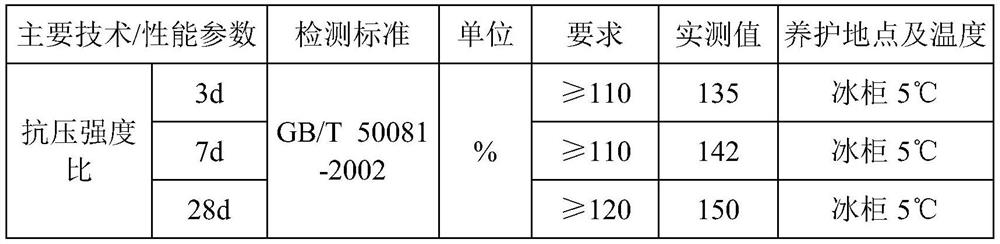

[0048] Experiments were carried out according to the above ratio, and the compressive strength ratio of the concrete test block mixed with the concrete reinforcing agent was measured, and the results are shown in Table 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com