Coastal saline-alkali soil improver and preparation method thereof

A soil improver and saline-alkali technology, which is applied in the field of coastal saline-alkali soil improver and its preparation, can solve the problems of beneficial inorganic salt loss and loss, and achieve the effects of soil structure improvement, soil barrier regulation and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of coastal saline-alkali soil improver, comprising the steps of:

[0028] S1. Weigh the straw, polyacrylamide, humus, wood vinegar, microbial agent and inorganic salt according to the mass ratio, mechanically crush the straw into debris and evenly mix with the humus;

[0029] S2, dilute the concentrated wood vinegar according to the ratio of 1:200, fully and uniformly mix and react with the straw and humus;

[0030] S3, dissolving polyacrylamide in water, and evenly spraying it on the above-mentioned mixed debris of straw and humus;

[0031] S4. Add microbial agent and inorganic salt, mix uniformly, granulate, and dry to obtain coastal saline-alkaline soil improver.

[0032] Its on-site preparation and application methods specifically include the following steps:

[0033] A. Take the straw, polyacrylamide, humus, wood vinegar, microbial agent and inorganic salt according to the size of the field and convert the mass ratio; break the straw and spre...

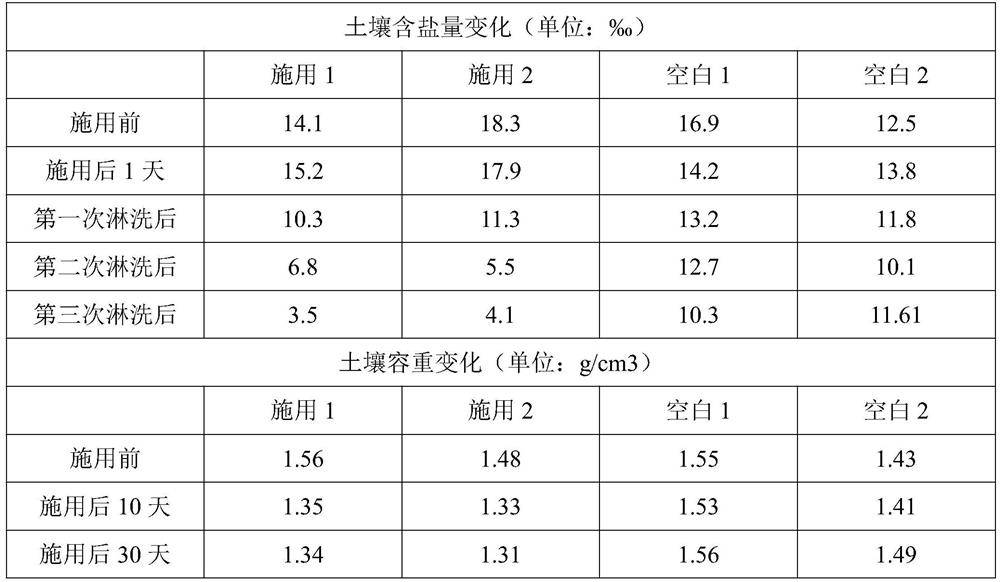

Embodiment 1

[0039] In the present embodiment, the total amount of preparing the soil physical and chemical properties improver of the present invention is 100kg, and the specific steps are:

[0040] S1. Weigh 30kg of straw, 10kg of polyacrylamide, 40kg of humus, 5kg of wood vinegar, 10kg of microbial agent and 5kg of inorganic salt according to the mass ratio, wherein the inorganic salt includes 1.75kg superphosphate, 1.75kg ammonium sulfate, 0.4kg sulfuric acid Magnesium, 0.5kg of ferric chloride, 0.25kg of ferrous sulfate, 0.15kg of calcium nitrate, 0.1kg of zinc sulfate, 0.1kg of sand, mechanically crush the straw into debris and evenly mix with humus;

[0041] S2, dilute the concentrated wood vinegar according to the ratio of 1:200, fully and uniformly mix and react with the straw and humus;

[0042] S3, dissolving polyacrylamide in water, and evenly spraying it on the above-mentioned mixed debris of straw and humus;

[0043] S4. Add microbial agent and inorganic salt, mix uniformly,...

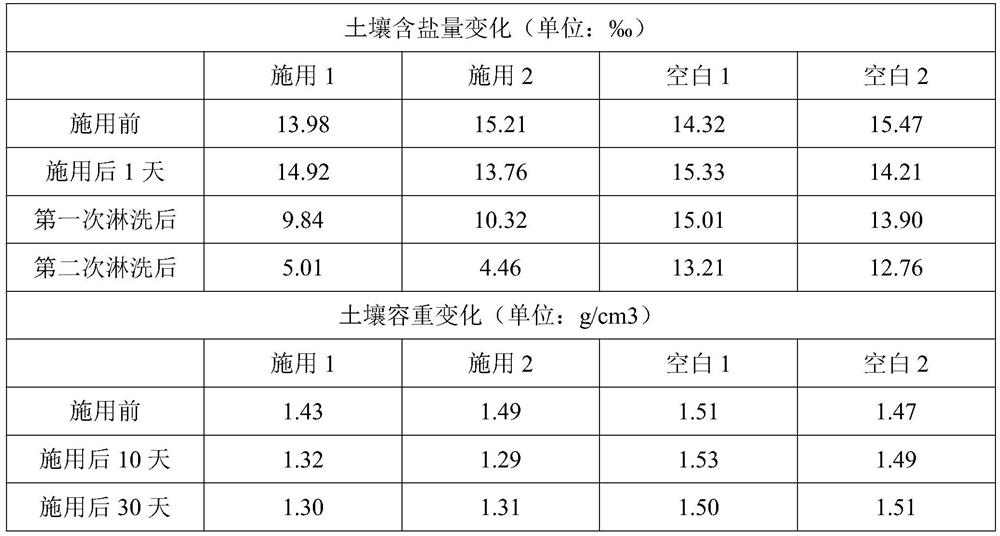

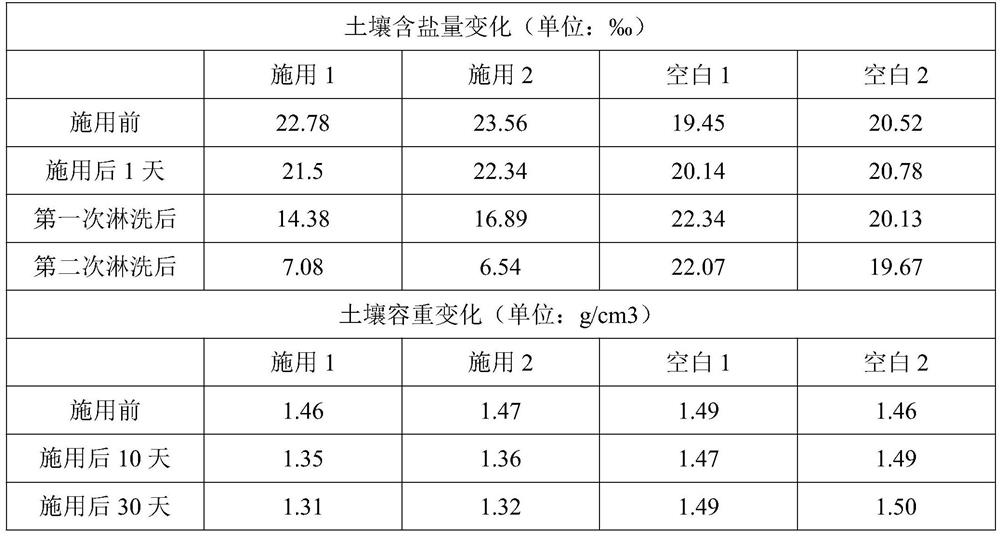

Embodiment 2

[0054] In the present embodiment, the total amount of preparing the soil physical and chemical properties improver of the present invention is 100kg, and the specific steps are:

[0055] S1. Weigh 40kg of straw, 20kg of polyacrylamide, 20kg of humus, 4kg of wood vinegar, 6kg of microbial agent and 10kg of inorganic salt according to the mass ratio. The inorganic salt includes 5kg of superphosphate, 2.5kg of ammonium sulfate, and 0.4kg of magnesium sulfate. , 0.5kg ferric chloride, 0.5kg ferrous sulfate, 0.5kg calcium nitrate, 0.3kg zinc sulfate, 0.3kg sand, mechanically crush the straw into debris and mix it with humus;

[0056] S2, dilute the concentrated wood vinegar according to the ratio of 1:200, fully and uniformly mix and react with the straw and humus;

[0057] S3, dissolving polyacrylamide in water, and evenly spraying it on the above-mentioned mixed debris of straw and humus;

[0058] S4. Add microbial agent and inorganic salt, mix uniformly, granulate, and dry to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com