Stable ternary composite material for hydrogen production by photocatalytic decomposition of water and preparation method thereof

A composite material and photocatalytic technology, which is applied in the field of catalytic material preparation, can solve the problem of not meeting the requirements of photocatalytic hydrogen production activity, and achieve the effects of efficient and stable photocatalytic water splitting for hydrogen production, promoting electron transfer, and improving separation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

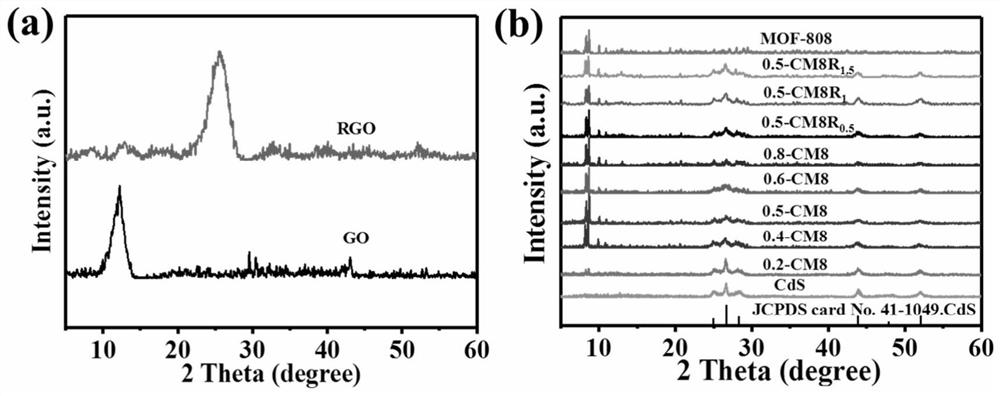

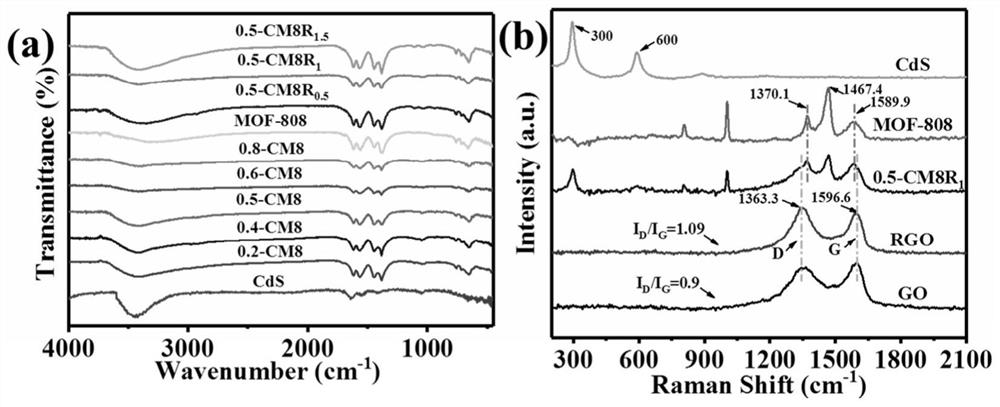

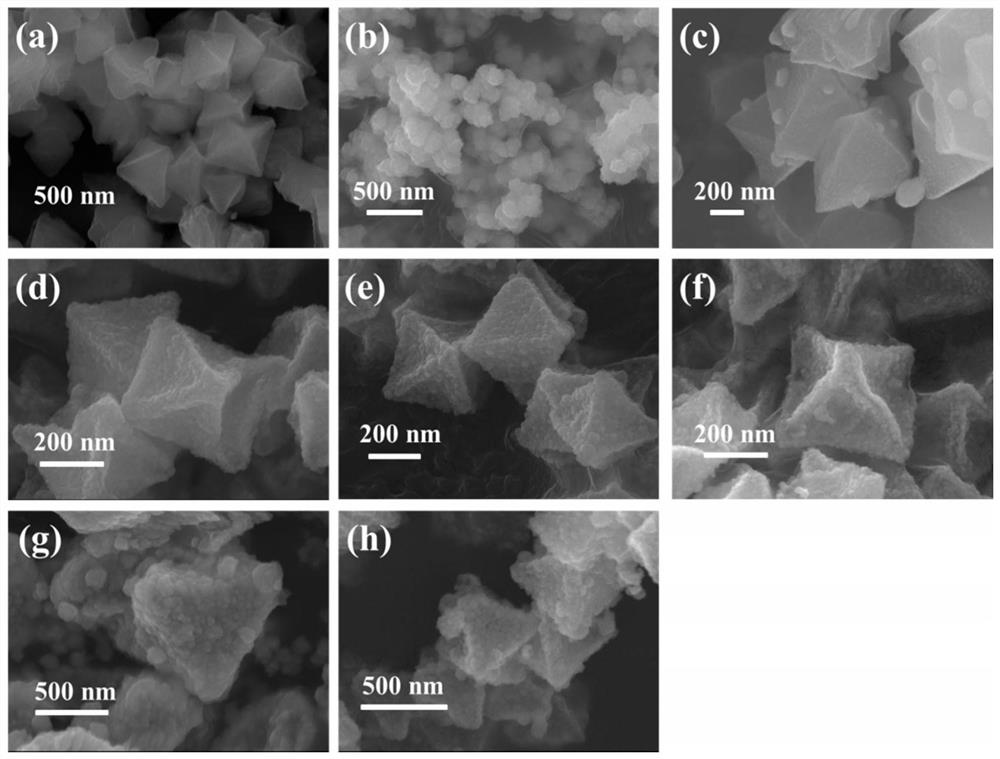

[0038] First, accurately weigh 5mg RGO and disperse it into 40mL ethanol solution, then put it into a 50mL polytetrafluoroethylene liner, ultrasonically treat it for 1h, then accurately weigh 1.00g, 0.50g, and 0.33g of MOF-808 and add them to the In the three PTFE liners, ultrasonically mix evenly; then put the three PTFE liners into steel kettles respectively, and keep them in an oven at 120°C for 12 hours. Washed three times with water and ethanol, and finally dried in a vacuum oven at 50 °C to obtain the MOF-808 / RGO composite, denoted as M8R Y . The three samples are respectively recorded as M8R according to the mass percentage of the added RGO and MOF-808 0.5 , M8R 1 , and M8R 1.5 ; Accurately weigh 0.1839g Cd(CH 3 COO) 2 2H 2 O (about 0.69mmol) was added to 40mL deionized water, ultrasonically dissolved, and then the composite material M8R was accurately weighed Y The mass is 0.5g, 0.25g, 0.2g, 0.167g, 0.125g, dispersed in the above solution, ultrasonic treatment f...

Embodiment 2

[0039] Example 2: Compared with Example 1, the recombination temperature of RGO and MOF-808 is 130°C.

[0040] First, accurately weigh 5mg RGO and disperse it into 40mL ethanol solution, then put it into a 50mL polytetrafluoroethylene liner, ultrasonically treat it for 1h, then accurately weigh 1.00g, 0.50g, and 0.33g of MOF-808 and add them to the In the three polytetrafluoroethylene linings, ultrasonically mix evenly; then put the three polytetrafluoroethylene linings into steel kettles respectively, keep them in an oven at 130°C for 12h, and after natural cooling, the products are separated into water and anhydrous Washed with ethanol three times, and finally dried in a vacuum oven at 50 °C to obtain the MOF-808 / RGO composite, denoted as M8R Y , The productive rate is slightly lower than that of Example 1. The three samples are respectively recorded as M8R according to the mass percentage of the added RGO and MOF-808 0.5 , M8R 1 , and M8R 1.5 ; Accurately weigh 0.1839g ...

Embodiment 3

[0041] Example 3: Compared with Example 1, the recombination temperature of CdS and MOF-808 / RGO is 50°C.

[0042] First, accurately weigh 5mg RGO and disperse it into 40mL ethanol solution, then put it into a 50mL polytetrafluoroethylene liner, ultrasonically treat it for 1h, then accurately weigh 1.00g, 0.50g, and 0.33g of MOF-808 and add them to the In the three PTFE liners, ultrasonically mix evenly; then put the three PTFE liners into steel kettles respectively, and keep them in an oven at 120°C for 12 hours. Washed three times with water and ethanol, and finally dried in a vacuum oven at 50 °C to obtain the MOF-808 / RGO composite, denoted as M8R Y . The three samples are respectively recorded as M8R according to the mass percentage of the added RGO and MOF-808 0.5 , M8R 1 , and M8R 1.5 ; Accurately weigh 0.1839g Cd(CH 3 COO) 2 2H 2 O (about 0.69mmol) was added to 40mL deionized water, ultrasonically dissolved, and then the composite material M8R was accurately weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com