A light-cured 3D printing metal-ceramic composite material and its preparation method

A ceramic composite material and 3D printing technology, which is applied in the field of additive manufacturing, can solve problems such as obstruction, low light transmission depth, and easy agglomeration, and achieve the effects of improving refraction effect, excellent wear resistance, and promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

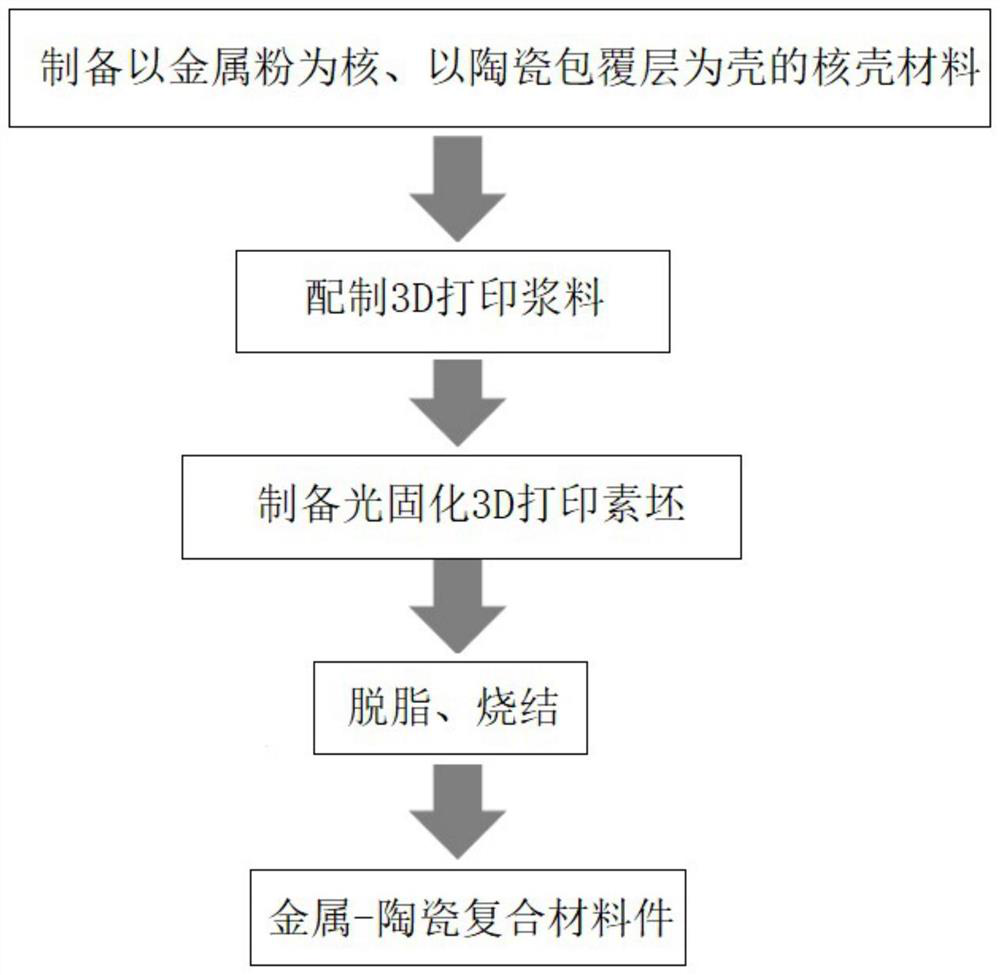

[0048] On the one hand, the embodiment of the present invention proposes a kind of preparation method of photocuring 3D printing metal-ceramic composite material, such as figure 1 As shown, it includes the following steps:

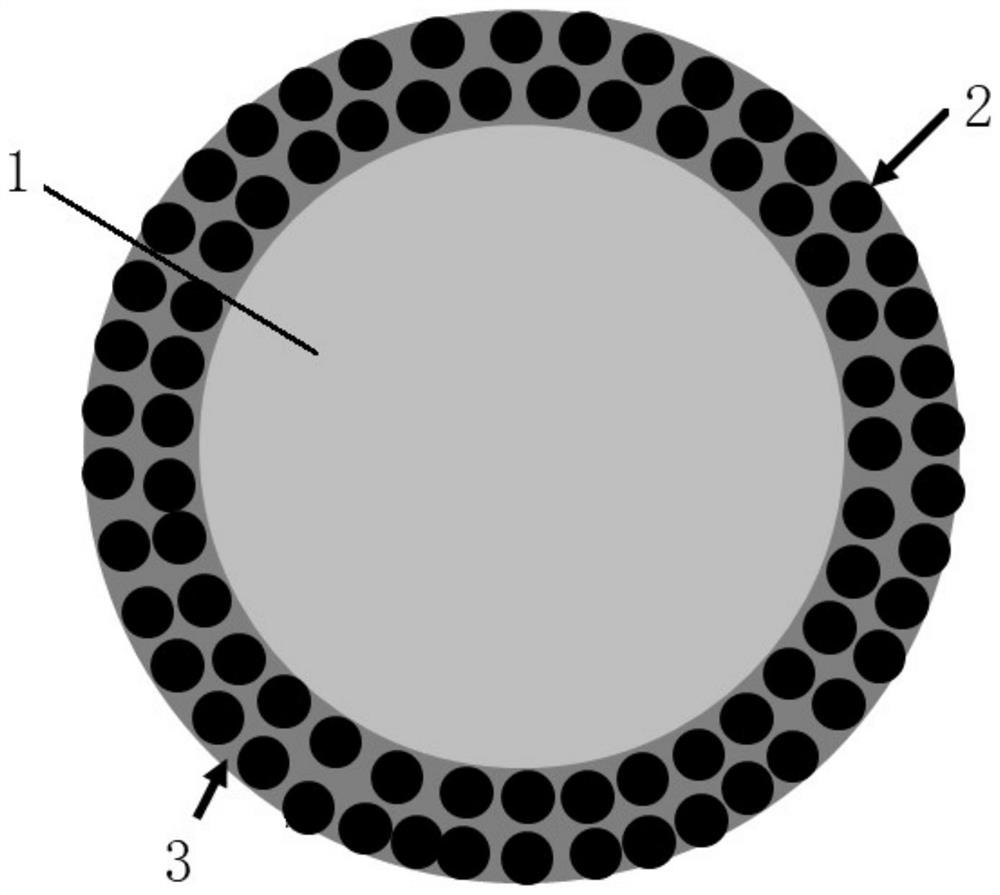

[0049] Prepare the core-shell material: mix the metal powder after the surface activation treatment and the ceramic powder after the surface activation treatment, add a surface curing agent and a surface polymerization initiator to it, and perform a coating step; After treatment, a core-shell material with metal powder as the core and a ceramic coating as the shell is obtained; wherein the metal powder is pure metal powder and / or alloy powder.

[0050] This step is specifically as follows: after mixing the metal powder and the metal surfactant, stir in a beaker with a constant temperature of 50-60° C. for 60-120 minutes with a mechanical stirrer to obtain the activated metal powder. After mixing the nano-ceramic powder and the ceramic surfactant, stir it ...

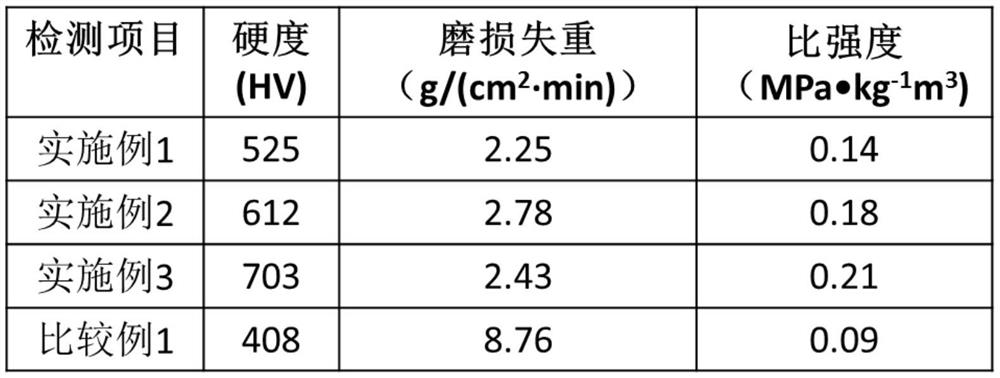

Embodiment 1

[0064] This embodiment prepares a light-cured 3D printing metal-ceramic composite material, comprising the following steps:

[0065] Preparation of core-shell material: Mix metal Ni powder and metal surfactant in a constant temperature 50°C beaker and stir for 60 minutes with a mechanical stirrer; ZrO 2 After the powder is mixed with the ceramic surfactant, stir it in a beaker at a constant temperature of 70°C for 90 minutes with a mechanical stirrer; mix the surface curing agent and the surface polymerization initiator in the beaker, and stir it mechanically for 5 minutes, then set aside. The activated metal Ni powder, the activated ZrO 2 The powders are mixed, and then in the process of mechanical stirring at a constant temperature of 80°C, the mixed solution of the surface curing agent and the surface polymerization initiator is slowly added thereto, and stirred at a constant temperature of 80°C for 10 hours. The product was taken out, washed with deionized water, and drie...

Embodiment 2

[0075] This embodiment prepares a light-cured 3D printing metal-ceramic composite material, comprising the following steps:

[0076] Prepare the core-shell material: alloy CoNiCrAlY powder (wherein, the mass fraction of Co is 54%, the mass fraction of Ni is 23%, the mass fraction of Cr is 17%, the mass fraction of Al is 5.5%, the mass fraction of Y is 0.5% %) is mixed with metal surface active agent and utilizes mechanical stirrer to stir 100 minutes in the beaker of constant temperature 60 ℃; Al 2 o 3 Mix the powder with the ceramic surfactant and stir it in a beaker with a constant temperature of 80°C for 120 minutes with a mechanical stirrer; mix the surface curing agent and the surface polymerization initiator in the beaker and stir it mechanically for 1 minute. The activated alloy CoNiCrAlY powder, Al 2 o 3 The powders are mixed, and then in the process of mechanical stirring at a constant temperature of 120°C, the mixed solution of the surface curing agent and the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com