Negative pressure forming process of fusion-cast aluminum oxide green brick and fusion-cast aluminum oxide green brick

A molding process and alumina technology, applied in ceramic molding machines, manufacturing tools, mold auxiliary parts, etc., can solve the problems of pollution, difficult processing, waste of resources and the environment, and achieve broad application prospects, great promotion value, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example-Basic Steps of Alumina Brick Blank Negative Pressure Forming Technology and Its Optimization

[0043] A negative pressure molding process for fused alumina brick embryos, comprising the following steps:

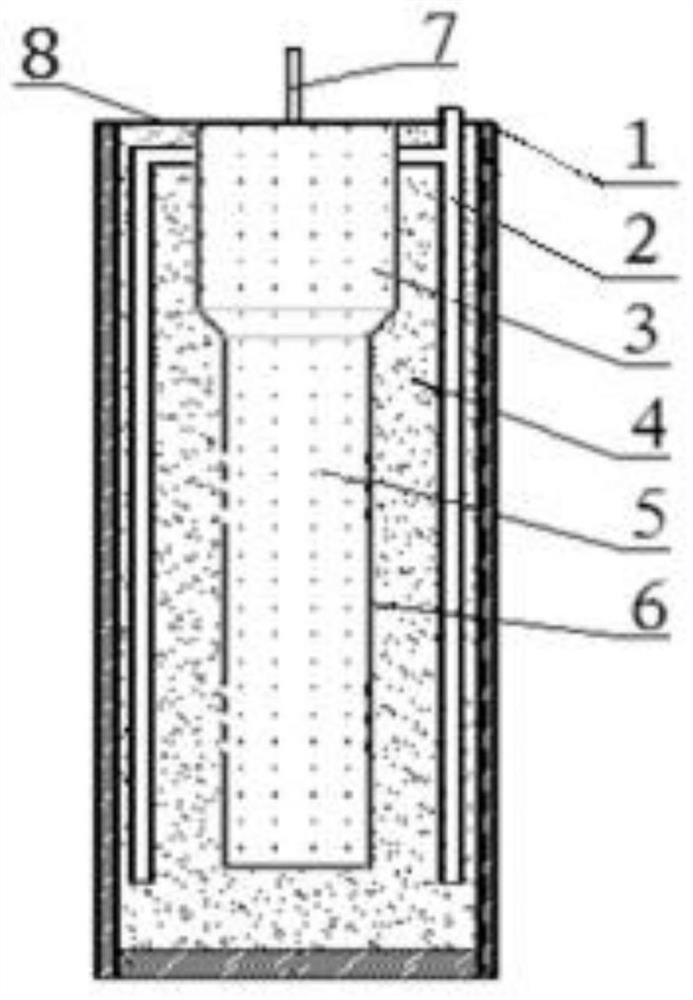

[0044] A. Make a mold according to the shape of the alumina brick embryo. There is a cavity in the middle of the mold. The outer surface and bottom surface of the mold are densely covered with air extraction holes that communicate with the cavity. The cavity is equipped with an air extraction pipe corresponding to the top surface of the mold. It is understandable that , the mold is set as a cavity and the outer surface and the bottom surface are densely covered with air holes, and the attached film can be attached to the surface of the mold by vacuuming.

[0045] B. Attach a film on the outer surface and bottom surface of the mold; it should be noted that the outer surface and bottom surface of the mold referred to here means that the middle surface of the mold...

Embodiment 2

[0074] Embodiment two molding sand quality control

[0075] Since the casting temperature of α-β alumina melt is very high, it is at least 150°C higher than that of AZS and other casting materials. Sand molding sand first requires SiO 2 It has high purity and high refractoriness to withstand the high temperature of the molten casting material. Secondly, it requires a finer grain size of the molding sand to meet the needs of molding processes such as good fluidity and high filling compactness. Experimental research shows that the moisture content of the new sand mold sand should be strictly controlled below 0.5-1%, otherwise "honeycomb" will appear in the sand mold during use, which will cause the box to collapse easily during casting. The new type of sand mold is suitable to use quartz sand whose particle size does not exceed a certain number of meshes. Two or more types of quartz sand cannot be mixed. After the mixed quartz sand is filled in the sand box, "segregation" will ...

Embodiment 3

[0079] Example 3 Negative pressure and time control of sand mold

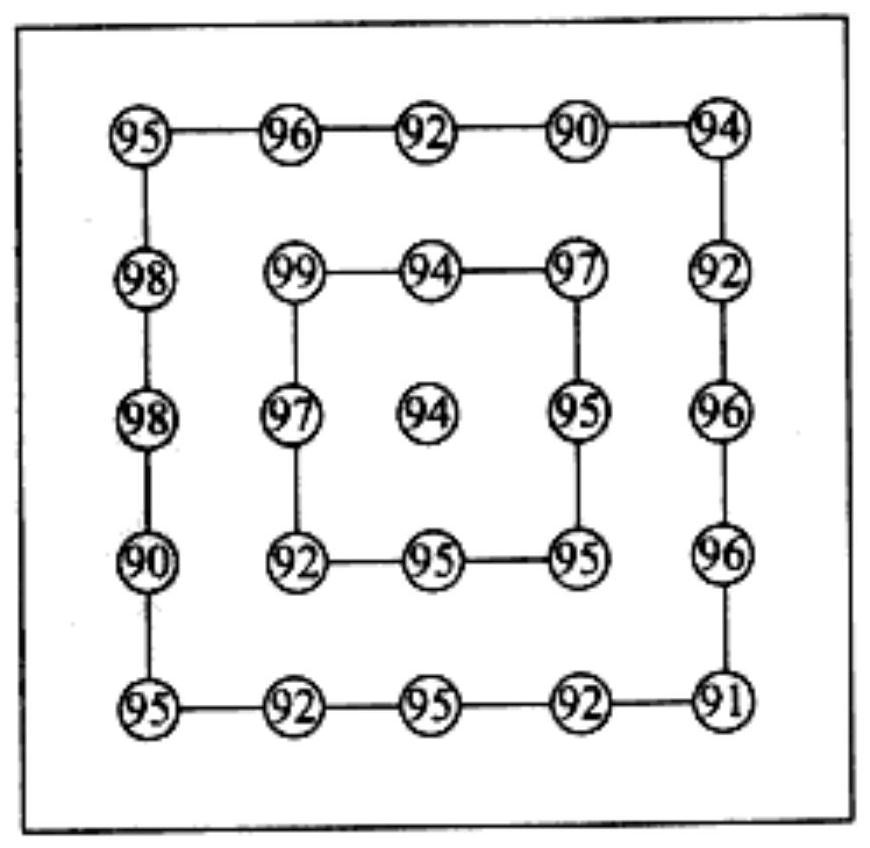

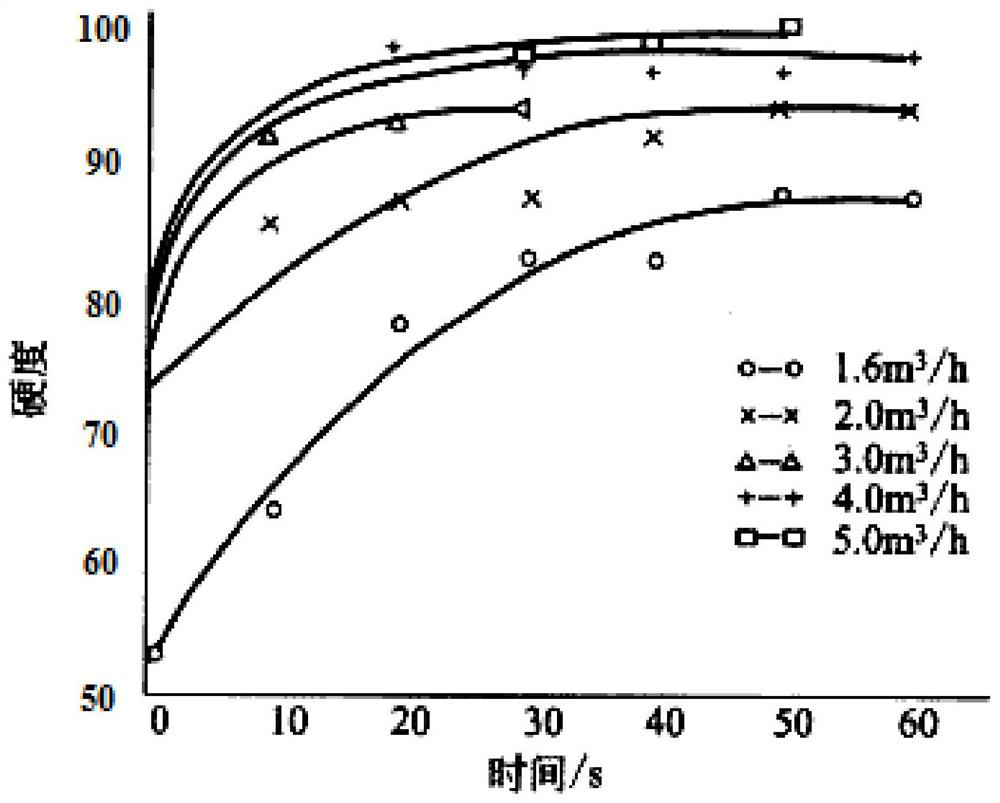

[0080] As attached to the manual Figure 2~3 As shown, the negative pressure control of the sand mold mainly depends on the two aspects of vacuum flow and time. Fill the sand box with dry quartz sand without binders and additives, start the vibrating table, shake the molding sand in the sand box, seal the lid of the sand box, open the air extraction valve, and extract the air in the sand. Create a pressure difference inside and outside the sand mold. Due to the effect of pressure difference or negative pressure, the sand mold has high hardness, and the reading of the sand mold hardness tester can generally reach 90-95. After the hardness of the molding sand in the sand box is stable, the sand molding is completed.

[0081] The relationship between the physical consolidation hardness of the molding sand and the pumping flow rate and pumping time of the vacuum system is as follows: image 3 shown. When the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com