Method for preparing lithium carbonate by taking lithium fluoride mother liquor as raw material

A technology of lithium fluoride and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, alkali metal fluoride, etc., can solve the problems of high cost and low product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

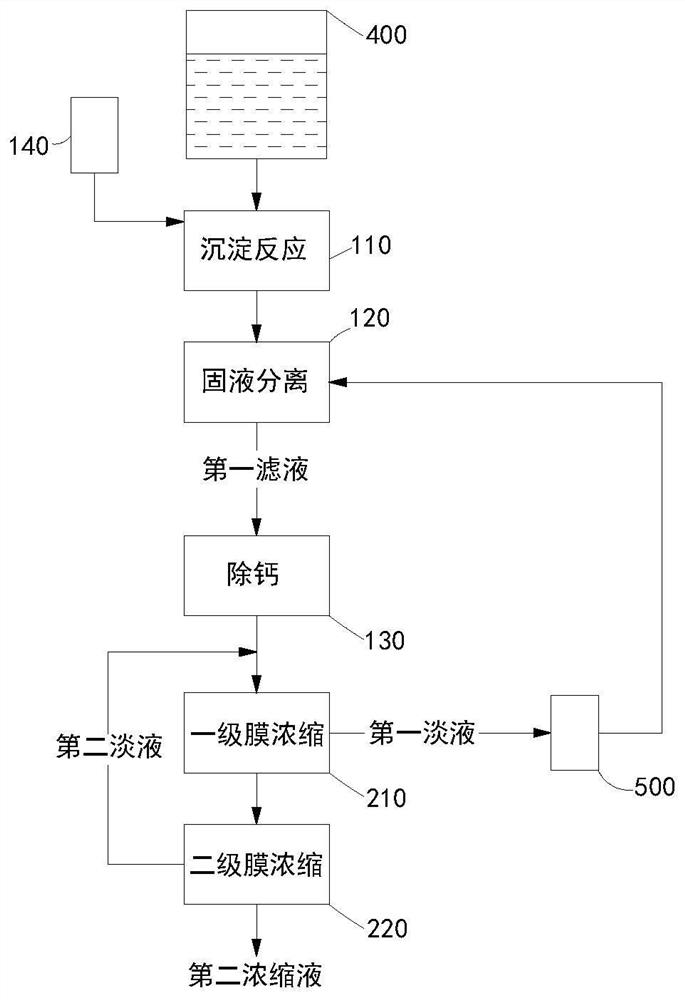

[0038] This embodiment provides the first specific implementation of the treatment method of lithium fluoride mother liquor and the first specific implementation of the treatment system of lithium fluoride mother liquor, wherein the lithium fluoride mother liquor is lithium salt and fluoride salt Or the lithium fluoride slurry generated by hydrofluoric acid reaction is obtained through crystallization and solid-liquid separation.

[0039] The processing method of lithium fluoride mother liquor comprises the following steps:

[0040] (1) Defluorination

[0041] Step1: Add calcium chloride to the lithium fluoride mother liquor to convert fluoride ions into calcium fluoride precipitates, and obtain a post-reaction liquid after the precipitation reaction is completed;

[0042] Step2: Perform solid-liquid separation on the reacted liquid to obtain the first filtrate; plate and frame filtration is used for solid-liquid separation, and the first filtrate includes the permeate and th...

Embodiment 2

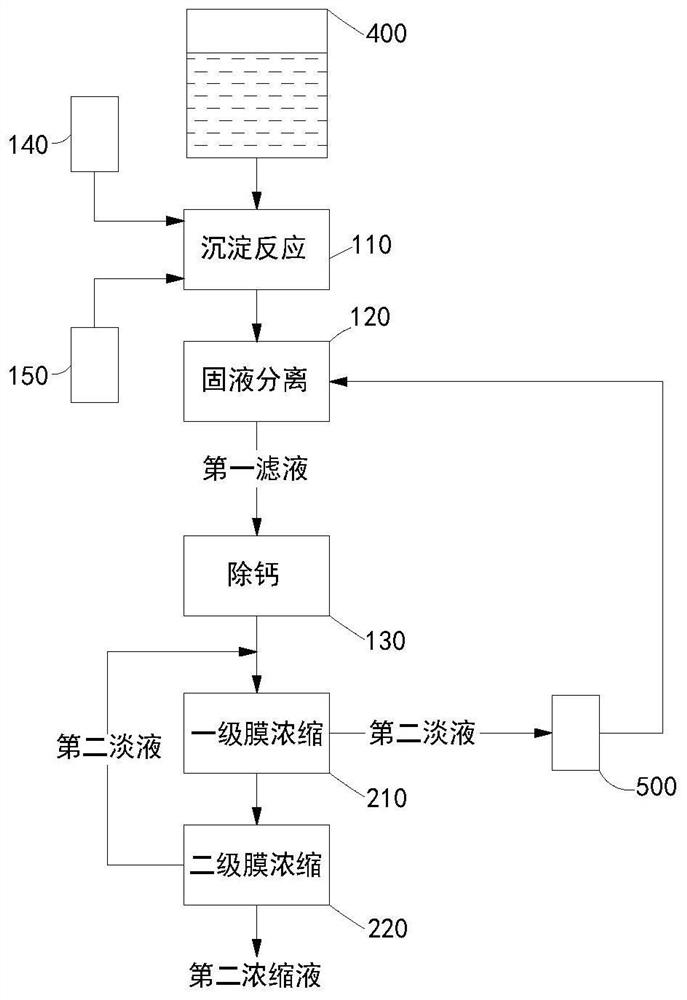

[0059] This embodiment provides the second specific implementation of the treatment method of lithium fluoride mother liquor and the second specific implementation of the treatment system of lithium fluoride mother liquor, wherein the lithium fluoride mother liquor is lithium salt and fluoride salt Or the lithium fluoride slurry generated by hydrofluoric acid reaction is obtained through crystallization and solid-liquid separation.

[0060] The difference compared with Example 1 is that the step (1) of the treatment method of the lithium fluoride mother liquor of the present embodiment specifically includes:

[0061] Step1: Add calcium chloride to the lithium fluoride mother liquor to convert fluoride ions into calcium fluoride precipitates;

[0062] Step2: Continue to add sodium carbonate to convert excess calcium ions into calcium carbonate precipitation, and obtain a post-reaction liquid after the precipitation reaction is completed;

[0063] Step3: Perform solid-liquid se...

Embodiment 3

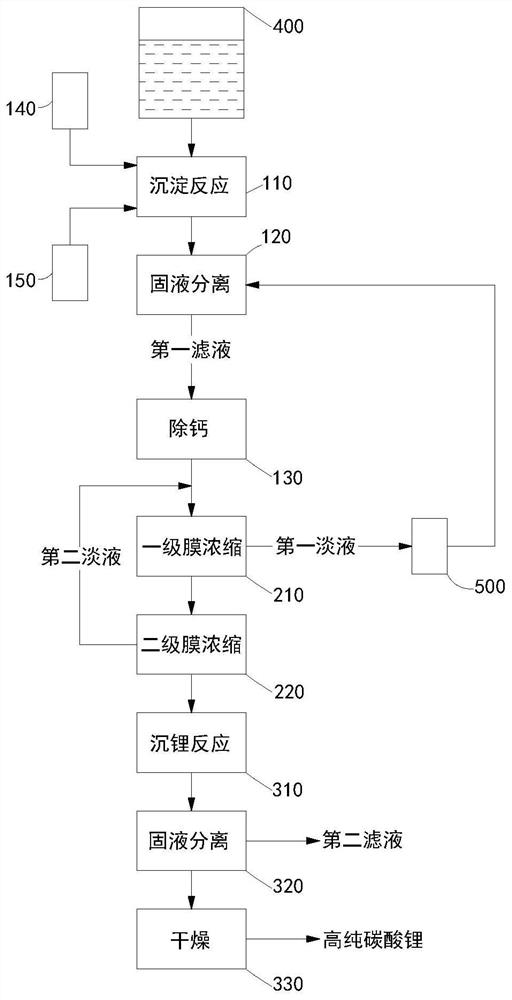

[0072] This embodiment provides the first embodiment of the method for preparing lithium carbonate from lithium fluoride mother liquor (that is, the third embodiment of the treatment method of lithium fluoride mother liquor) and the treatment system of lithium fluoride mother liquor The third specific implementation manner of the present invention, wherein the lithium fluoride mother liquor is obtained by crystallization and solid-liquid separation of lithium fluoride slurry formed by the reaction of lithium salt and fluoride radical salt or hydrofluoric acid.

[0073] The method for preparing lithium carbonate as raw material with lithium fluoride mother liquor comprises steps:

[0074] (1) Defluorination

[0075] Step1: Add calcium chloride to the lithium fluoride mother liquor to convert fluoride ions into calcium fluoride precipitates;

[0076] Step2: Continue to add sodium carbonate to convert excess calcium ions into calcium carbonate precipitation, and obtain a post-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com