Acetylene diol polyether and preparation method thereof

A technology of acetylene glycol polyether and acetylene glycol, which is applied in the field of acetylene glycol polyether and its preparation, can solve problems such as high cost and complex process, and achieve the effects of low production cost, high catalytic activity, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

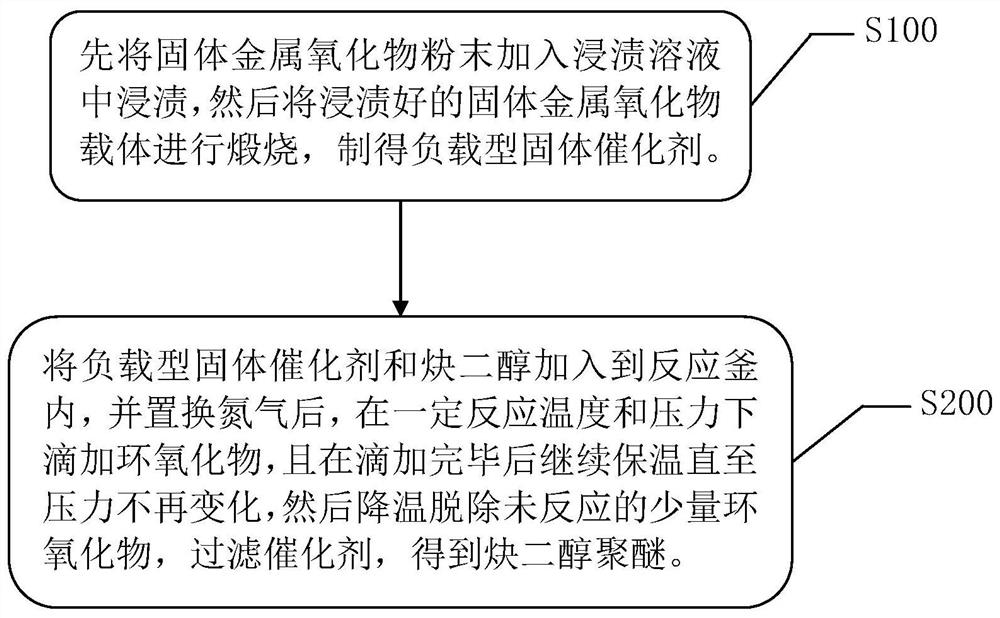

[0030] Such as figure 1 Shown, the preparation method of acetylenic glycol polyether of the present invention comprises the following steps:

[0031] Step 100. First add the solid metal oxide support to the impregnation solution for impregnation, and then calcinate the impregnated solid metal oxide support to obtain a supported solid catalyst; the impregnation time is preferably 8 hours, and the calcination temperature is preferably 500°C ~550°C, the calcination time is preferably 5 hours; the specific operation can be: first add the solid metal oxide carrier to the impregnation solution for 8 hours, and then put the impregnated solid metal oxide carrier into the muffle furnace, at 500- Calcined at 550°C for 5 hours to obtain a supported solid catalyst.

[0032] Step 200. Add the supported solid catalyst and acetylenic diol into the reaction kettle, and replace the nitrogen in the reaction kettle, add epoxy oxide dropwise at a certain reaction temperature and pressure, and co...

Embodiment 1

[0040] First put 226g of molten 2,4,7,9-tetramethyl-5-decyne-4,7-diol into the polymerization reactor, then drop into 2.6g of loaded solid catalyst, the loaded solid catalyst consists of 10%wt Al impregnation with phosphoric acid solution 2 o 3 The carrier was prepared by calcination; then after the feeding was completed, the air in the kettle was replaced with nitrogen twice, and at the same time, the stirring was started to fully mix the materials; then the temperature of the reaction kettle was raised to 60°C, and 176g ring Ethylene oxide and 116g propylene oxide, and control the reaction temperature in the kettle to 60±2°C and the pressure in the kettle to 0.3-0.5MPa, and continue to ripen the reaction until the pressure does not change after the dropwise addition, and the ripening temperature is 60±2 °C; finally, after the aging reaction is completed, vacuum remove traces of unreacted ethylene oxide and propylene oxide, lower the temperature to 50 °C, and filter to obtai...

Embodiment 2

[0053] First put 226g of molten 2,4,7,9-tetramethyl-5-decyne-4,7-diol into the polymerization reactor, and then put into 6.34g of supported solid catalyst, which is 10%wt nitric acid Potassium solution impregnated Al 2 o 3 The carrier was prepared by calcination; then, after the feeding was completed, the air in the kettle was replaced with nitrogen for 2 times, and at the same time, the stirring was started to fully mix the materials; then the temperature of the reaction kettle was raised to 90°C, and 176g ring Ethylene oxide and 232g propylene oxide, and control the reaction temperature in the kettle to 90±2°C and the pressure in the kettle to 0.3-0.5MPa, and continue to ripen the reaction until the pressure does not change after the dropwise addition is completed, and the ripening temperature is 90±2 °C; Finally, after the aging reaction is completed, vacuum remove traces of unreacted ethylene oxide and propylene oxide, lower the temperature to 50 °C, and filter to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com