Diesel engine waste heat recovery and utilization system based on steam reforming of methanol to produce hydrogen

A technology of reforming hydrogen production and waste heat recovery, which is applied in the direction of charging system, hydrogen/synthesis gas production, hydrogen, etc., which can solve the problem of inability to meet the recovery of waste heat and energy utilization of marine diesel engines, the difficulty of fully recovering waste heat, and optimizing in-cylinder combustion and other issues, to achieve the effect of improving comprehensive utilization efficiency, reducing ship energy consumption, and improving combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

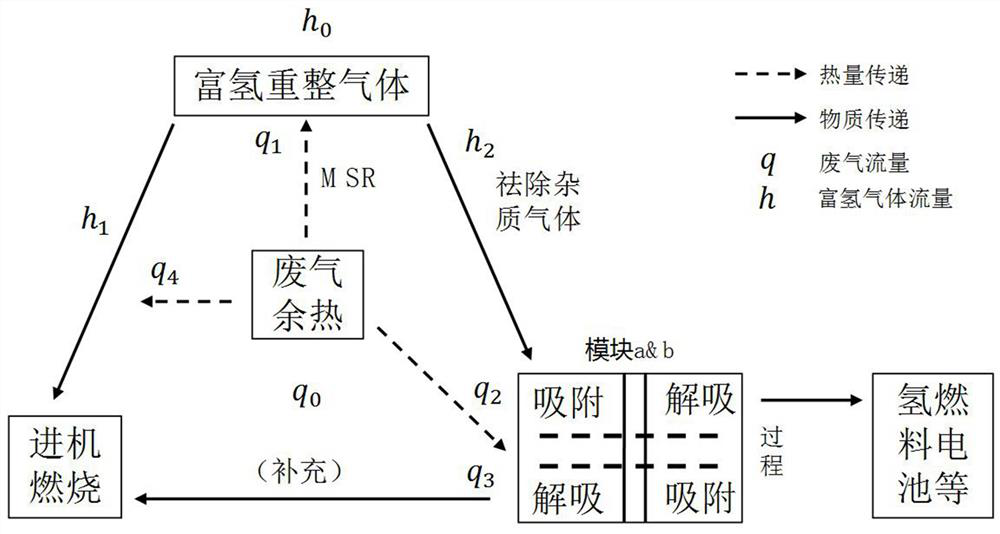

[0066] In this example, the exhaust gas discharge temperature of the marine diesel engine is 500-700K, and the reaction temperature range of methanol steam reforming for hydrogen production is 450-600K. If magnesium-based hydrogen storage alloy is selected as the hydrogen storage material, the adsorption temperature of hydrogen The range is 400-500K, and the hydrogen desorption temperature range is 450-550K.

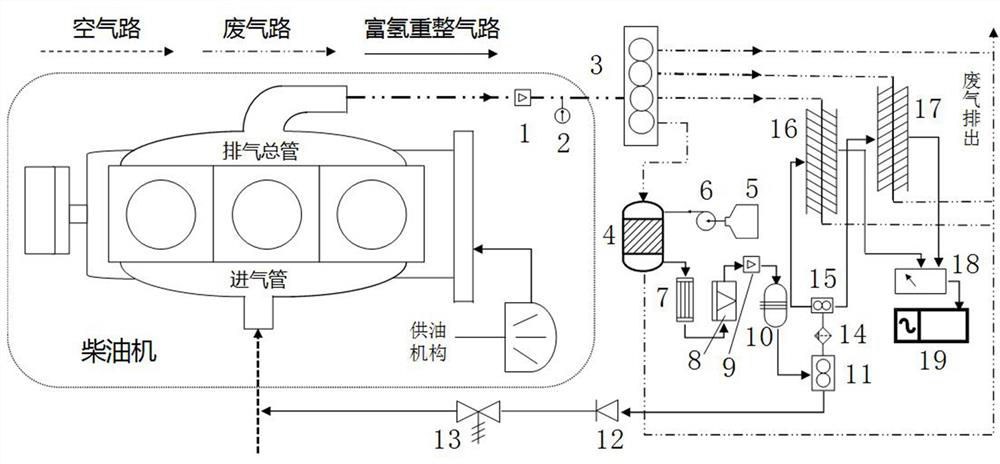

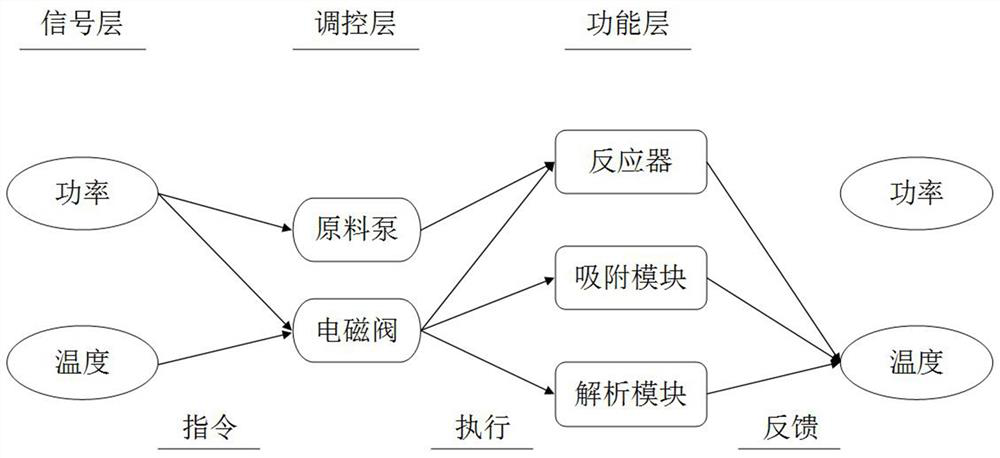

[0067] The exhaust gas discharged from the marine diesel engine is divided into four paths by the gas distribution device (controlled by the solenoid valve), and enters the reforming reactor, the adsorption hydrogen storage device a and b respectively to provide heat for the reaction and hydrogen adsorption and desorption, and the remaining exhaust gas is bypassed and discharged. atmosphere. At this time, the mixed vapor of methanol and water in the reforming reactor reacts to generate hydrogen-rich reformed gas, which is cooled (cooling device 7) and dried (drying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com