Flexible positive and negative electrode material for high-performance magnesium-lithium double-salt ion battery and preparation method thereof

A technology of positive electrode material and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insufficient electrochemical performance of magnesium-lithium double-salt batteries, poor electrical conductivity and structural stability, and low activity of negative electrode materials. , to achieve the effect of improving capacity and cycle stability, inhibiting surface passivation, and improving the activity of electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

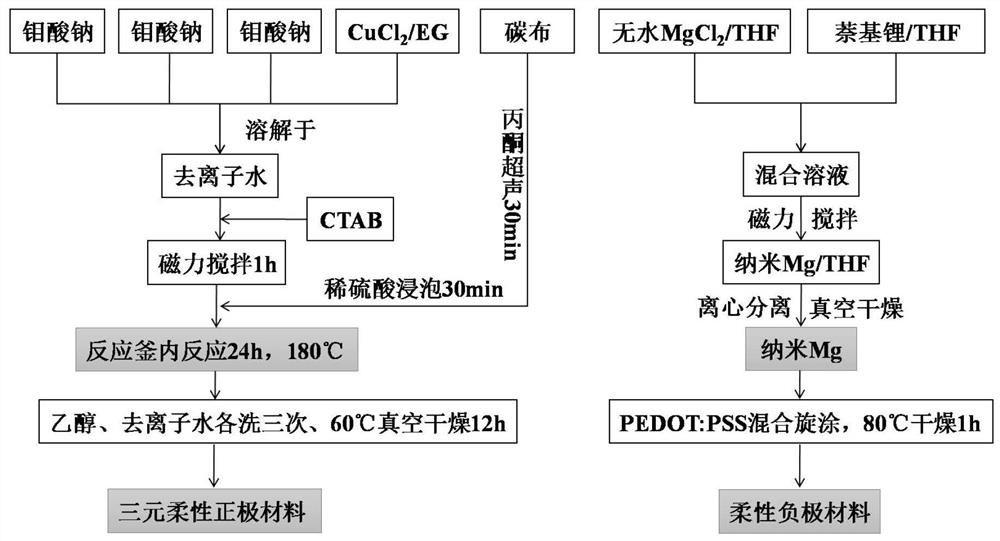

[0037] A method for preparing a flexible electrode composite material for a magnesium-lithium double-salt battery, comprising the following steps;

[0038] Preparation of flexible cathode materials for magnesium-lithium double-salt batteries:

[0039] Step 1, carbon cloth pretreatment:

[0040] 1) First, soak 0.7g of carbon cloth in acetone and sonicate for 10min.

[0041] 2) Next, soak the carbon cloth with dilute sulfuric acid for 20 minutes

[0042] 3) Finally, the carbon cloth soaked in dilute sulfuric acid was washed with ethanol and deionized water respectively, and then taken out and dried for later use.

[0043] Step 2, preparation of precursor solution:

[0044] Put 0.7g of sodium molybdate, 0.5g of hydroxylamine hydrochloride, 1.46g of thiourea, 0.068g of copper chloride and 0.018g of EG into a beaker, then add 40mL of deionized water, and stir with a glass rod to aid in dissolution. After dissolving, weigh 0.15 g of cetyltrimethylammonium bromide (CTAB) and add ...

Embodiment 2

[0055] A method for preparing a flexible electrode composite material for a magnesium-lithium double-salt battery, comprising the following steps;

[0056] Preparation of flexible cathode materials for magnesium-lithium double-salt batteries:

[0057] Step 1, carbon cloth pretreatment:

[0058] 1) First, soak 0.7g of carbon cloth in acetone for 20min and sonicate.

[0059] 2) Next, soak the carbon cloth with dilute sulfuric acid for 30 minutes

[0060] 3) Finally, the carbon cloth soaked in dilute sulfuric acid was washed with ethanol and deionized water respectively, and then taken out and dried for later use.

[0061] Step 2, preparation of precursor solution:

[0062] Put 0.88g of sodium molybdate, 0.725g of hydroxylamine hydrochloride, 1.52g of thiourea, 0.136g of copper chloride and 0.012g of EG into a beaker, then add 50mL of deionized water, and stir with a glass rod to aid in dissolution. After dissolving, 0.18 g of cetyltrimethylammonium bromide (CTAB) was weighed...

Embodiment 3

[0073] A method for preparing a flexible electrode composite material for a magnesium-lithium double-salt battery, comprising the following steps;

[0074] Preparation of flexible cathode materials for magnesium-lithium double-salt batteries:

[0075] Step 1, carbon cloth pretreatment:

[0076] 1) First, soak 0.7g of carbon cloth in acetone for 30min and sonicate.

[0077] 2) Next, soak the carbon cloth with dilute sulfuric acid for 40 minutes

[0078] 3) Finally, the carbon cloth soaked in dilute sulfuric acid was washed with ethanol and deionized water respectively, and then taken out and dried for later use.

[0079] Step 2, preparation of precursor solution:

[0080] Put 0.9g of sodium molybdate, 0.8g of hydroxylamine hydrochloride, 1.58g of thiourea, 0.204g of copper chloride and 0.006g of EG into a beaker, then add 60mL of deionized water, and stir with a glass rod to aid in dissolution. After dissolving, 0.2 g of cetyltrimethylammonium bromide (CTAB) was weighed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com