Method for preparing high-purity magnesium oxide by taking bischofite as raw material

A bischofite and magnesia technology, applied in the direction of magnesia, can solve the problems of waste of resources, damage of excess magnesium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 10g of bischofite, put the bischofite into a high-temperature furnace, and raise the temperature to 700°C, 800°C, and 900°C at a rate of 5°C / min in an air atmosphere, and keep the bischofite for 2 hours. , take out the calcined product, clean the calcined product in an ultrasonic cleaner for 2 hours, filter and wash it with water, dry it in an oven for 2 hours, and then place it in a muffle furnace for calcination at 700°C for 1 hour to obtain the target product magnesium oxide.

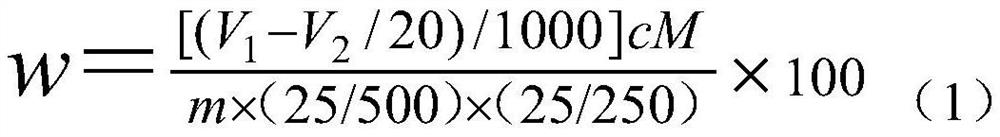

[0033] Weigh (5±0.0002)g sample, put it into a 250ml beaker, add 55ml hydrochloric acid solution, stir well until completely dissolved, filter with medium-speed quantitative filter paper to remove hydrochloric acid insoluble matter. Transfer the filtrate into a 500ml volumetric flask, add water to dilute to the mark, and record it as solution A.

[0034]Pipette 25ml of solution A into a 250ml volumetric flask, dilute with water to the mark. Use a pipette to pipette 25ml of this solution...

Embodiment 2

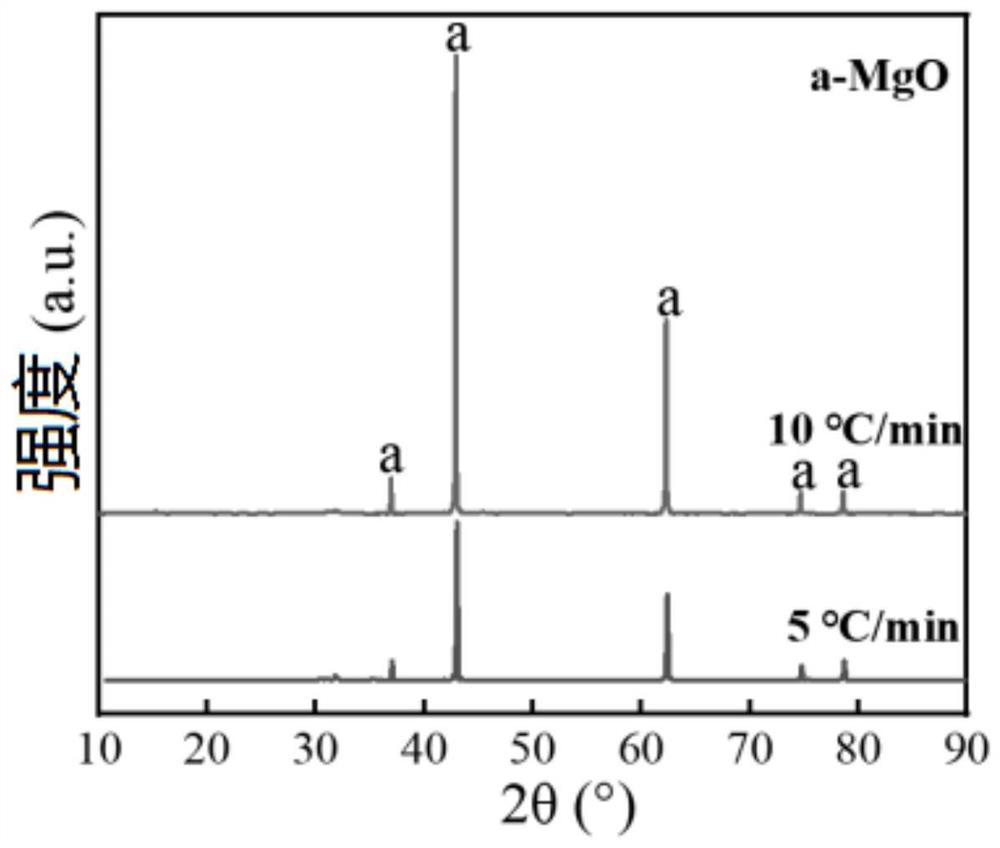

[0041] Weigh 10g of bischofite, put the bischofite into a high-temperature furnace, raise the temperature to 700°C at a rate of 5, 10, and 15°C / min in an air atmosphere, keep the bischofite for 2 hours, and take out Calcined product, XRD detection is carried out to the product obtained, such as figure 1 shown. The calcined product was cleaned in an ultrasonic cleaner for 2 hours, filtered and washed with water, dried in an oven for 2 hours, and then calcined in a muffle furnace at 700 for 1 hour to obtain the target product magnesium oxide.

[0042] Weigh (5±0.0002)g sample, put it into a 250ml beaker, add 55ml hydrochloric acid solution, stir well until completely dissolved, filter with medium-speed quantitative filter paper to remove hydrochloric acid insoluble matter. Transfer the filtrate into a 500ml volumetric flask, add water to dilute to the mark, and record it as solution A.

[0043] Pipette 25ml of solution A into a 250ml volumetric flask, dilute with water to the ...

Embodiment 3

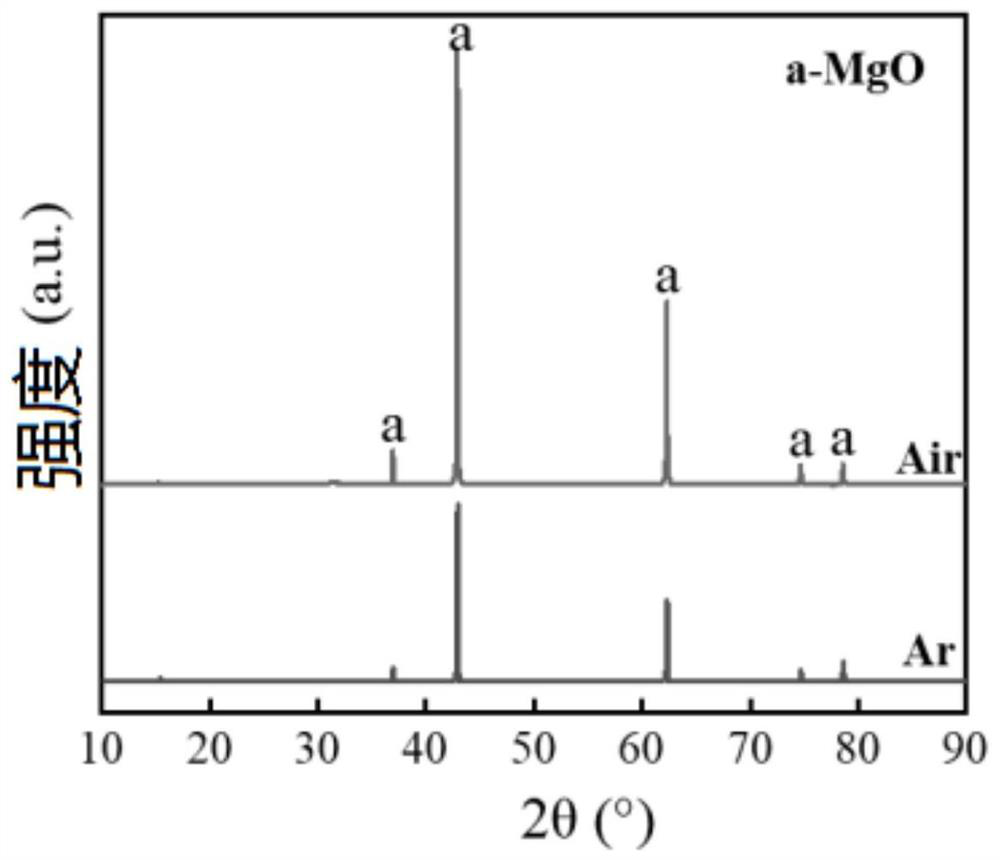

[0050] Weigh 10g bischofite, put the bischofite into a high-temperature furnace, raise the temperature up to 700°C at a rate of 5°C / min under air and argon atmosphere, keep the bischofite for 2 hours, and take out the calcined product , carry out XRD detection to the obtained product, such as figure 2 shown. The calcined product was cleaned in an ultrasonic cleaner for 2 hours, filtered and washed with water, dried in an oven for 2 hours, and then calcined in a muffle furnace at 700°C for 1 hour to obtain the target product magnesium oxide.

[0051] Weigh (5±0.0002)g sample, put it into a 250ml beaker, add 55ml hydrochloric acid solution, stir well until completely dissolved, filter with medium-speed quantitative filter paper to remove hydrochloric acid insoluble matter. Transfer the filtrate into a 500ml volumetric flask, add water to dilute to the mark, and record it as solution A.

[0052] Pipette 25ml of solution A into a 250ml volumetric flask, dilute with water to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com