Metal atom loaded nano composite material and preparation method thereof

A technology of nanocomposite materials and metal atoms, applied in the field of nanocomposite materials supported by metal atoms and its preparation, can solve the problems of high cost of composite materials, easy aggregation of metal atoms, difficult industrial production, etc., to achieve improved performance and uniform distribution of atoms , the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

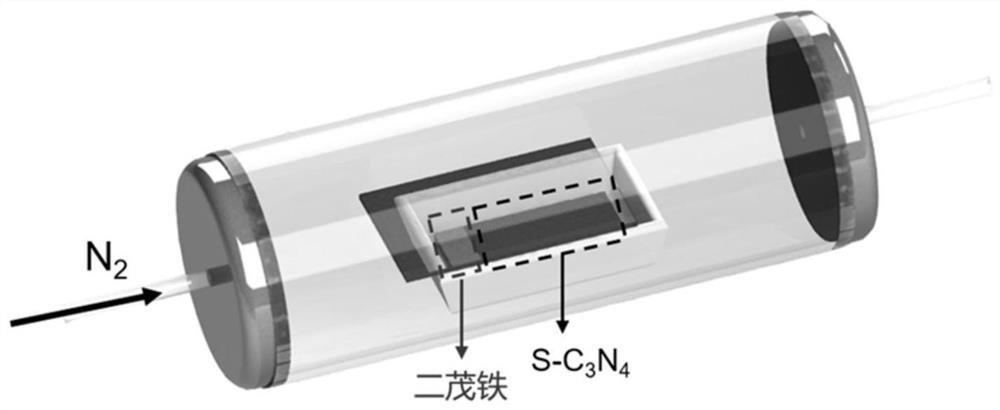

[0028] see figure 1 , a method for preparing a metal atom-supported nanocomposite material by chemical vapor deposition according to an embodiment of the present invention, comprising the following steps:

[0029] Step 1, using melamine as nitrogen source and carbon source and L-cysteine at a certain mass ratio and mixing in a ball mill for one hour, and mixing the two powders evenly;

[0030] Step 2: Put the mixed powder in a crucible, cover it with a ceramic piece, put it into a tube furnace, raise the temperature to 500°C-600°C at a certain heating rate in an inert gas atmosphere, and keep it warm for a certain period of time to obtain block, Lightly sulfur-doped C with low density 3 N 4 carrier;

[0031] Step 3, the resulting sulfur-doped C 3 N 4 Use a ball mill to make powder;

[0032] Step 4, the sulfur-doped C 3 N 4 Place them on the upstream and downstream of the air flow in the crucible respectively, and cover with ceramic tiles, so that C 3 N 4 Leave a ga...

Embodiment 1

[0042] see Figure 1 to Figure 5 , a method for preparing a metal atom-supported nanocomposite material according to an embodiment of the present invention, comprising the following steps:

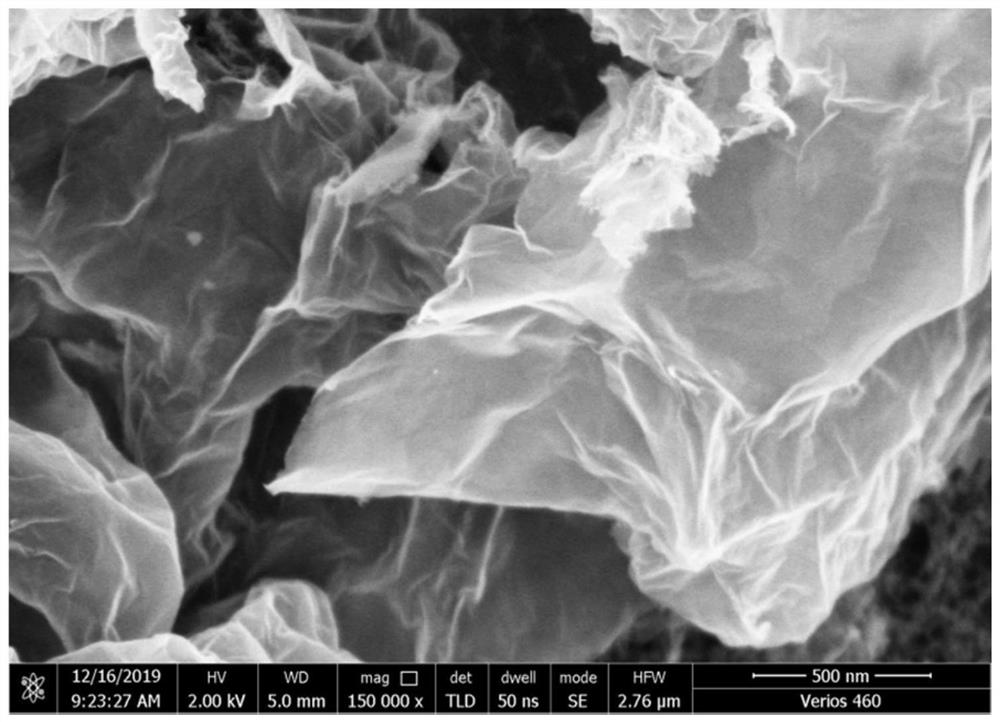

[0043] Mix 8.00g melamine and 2.00g L-cysteine in a ball mill for one hour, and mix the two powders evenly; then put the mixed powder in a crucible and cover it with a ceramic sheet, and heat up at a rate of 2°C / min to 600°C, and keep it warm for 120min, to obtain massive, low-density light sulfur-doped C 3 N 4 . Disperse 500 mg of the prepared material in 250 mL of HNO 3 (0.5mol L -1 ) in ultrasonic dispersion. Add 3.125mL of GO dispersion (1mg mL -1 ) and stirred for 6h to obtain a homogeneous dispersion. The final product was collected by filtration, washed three times with deionized water and ethanol, respectively, and then dried in a freeze dryer for 12 h to obtain the precursor.

[0044] Put ferrocene with a mass ratio of 5% on the side of the precursor, cover the crucible ...

Embodiment 2

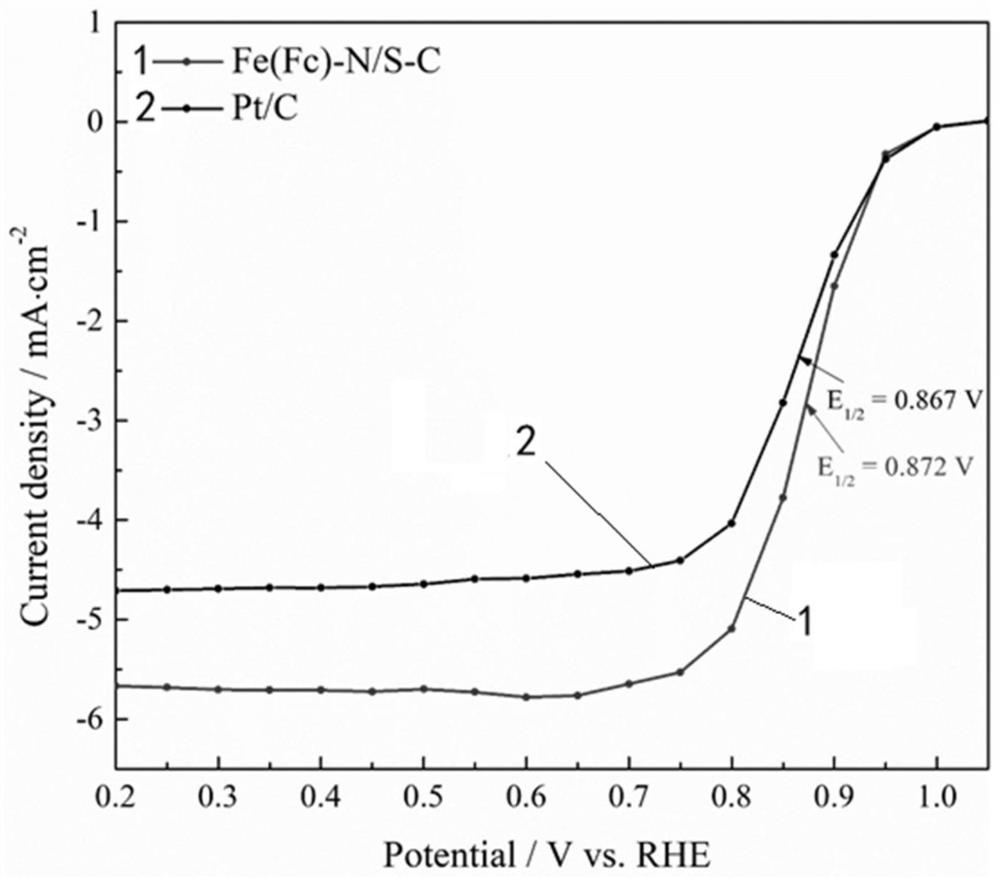

[0047] A method for preparing a metal atom-supported nanocomposite material according to an embodiment of the present invention includes: dispersing and depositing metal atoms in the form of isolated or atomic clusters on a nano-carbon-based material carrier and carbonizing them under an inert gas atmosphere to obtain Nanocomposites supported by metal atoms;

[0048] Wherein, the metal atom is an iron atom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com