Molecular film fermentation method of bio-organic fertilizer

A technology of bio-organic fertilizer and fermentation method, which is applied in the field of molecular membrane fermentation of bio-organic fertilizer, can solve the problems of burning roots and seedlings, long fermentation cycle, etc., and achieve the effects of low depreciation, complete decay and aging, and short installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

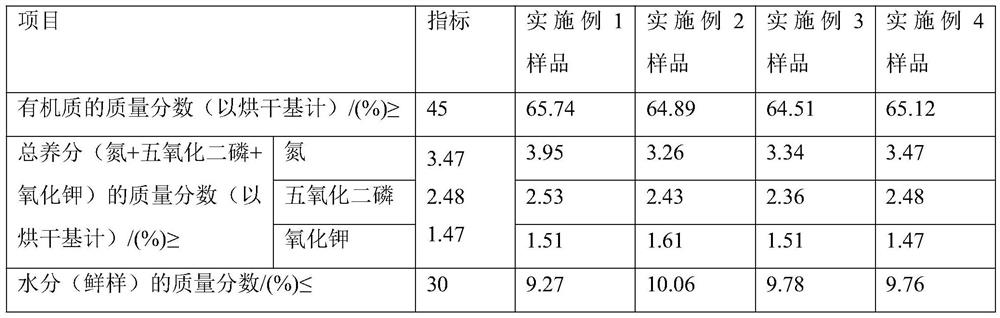

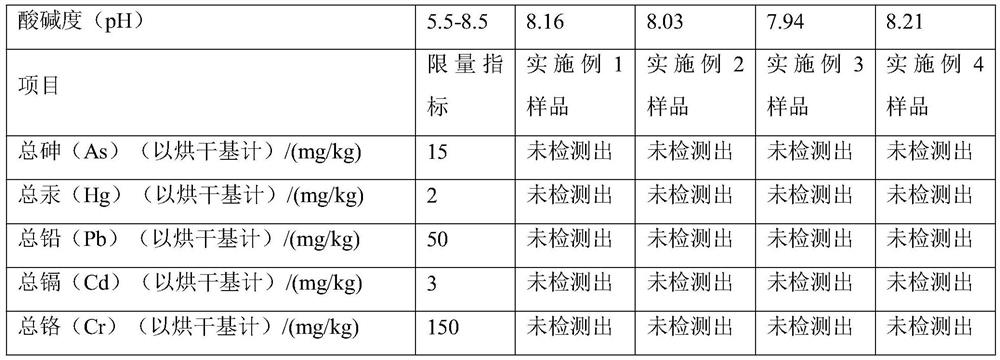

Embodiment 1

[0031] Molecular membrane fermentation method of bio-organic fertilizer:

[0032] Bio-organic fertilizer raw materials are pulverized and mixed - sprayed with bacteria agent and stirred evenly - pushed into the fermentation tank to pile up - covered with compost polymer film - decomposed and fermented - aged - tested - air-dried, screened and bagged.

[0033] Bio-organic fertilizer raw materials: 600kg of chicken manure, 200kg of cassava, 200kg of straw, 300kg of water, 1-2kg of organic fermentation bacteria (the organic fermentation bacteria contain 80% of lactic acid bacteria, 15% of yeast, 2% of Bacillus subtilis, saccharification Bacteria 3%), 1-2kg brown sugar. C / N ratio is 28:1, pH8.0.

[0034] The moisture of the organic fertilizer raw materials is controlled between 50-60%, the C / N ratio is controlled between 25-40:1, preferably 25-30:1, pH5.5-9.0, and the best range of pH: 6.5-8.0 .

[0035] 1. The fermentation raw materials chicken manure, cassava and straw are cr...

Embodiment 2

[0042] Bio-organic fertilizer raw materials: 400kg of cow dung, 200kg of mushroom dregs, 100kg of straw, 200kg of water, 1-2kg of organic fermentation bacteria (organic fermentation bacteria contain 80% of lactic acid bacteria, 15% of yeast, 2% of Bacillus subtilis, Saccharification bacteria 3%), 1-2kg brown sugar. C / N ratio is 30:1, pH8.3.

[0043] Concrete fermentation method is with embodiment 1.

Embodiment 3

[0045] Bio-organic fertilizer raw materials: 500kg of pig manure, 200kg of cassava, 100kg of straw, 250kg of water, 1-2kg of organic fermentation bacteria (organic fermentation bacteria contain 80% of lactic acid bacteria, 15% of yeast, 2% of Bacillus subtilis, saccharification Bacteria 3%), 1-2kg brown sugar. C / N ratio is 31:1, pH7.8.

[0046] Concrete fermentation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com