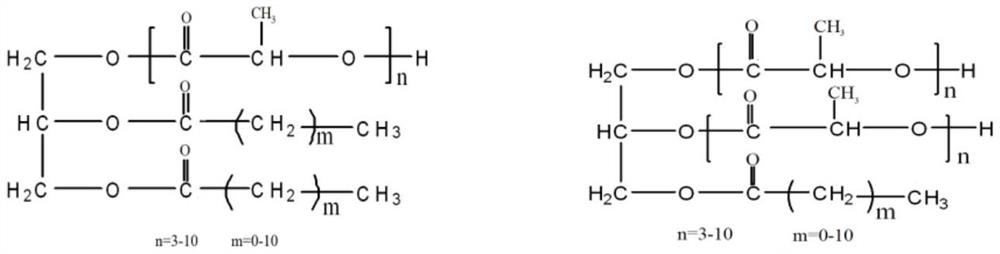

Polylactic acid plasticizer and preparation method thereof

A plasticizer, polylactic acid technology, applied in the toughening and modification of polylactic acid transparent products, and the field of polylactic acid plasticizers, can solve the problems of high brittleness of polylactic acid resin, limited application scope, poor toughness, etc. Elongation at break, improvement in processability, effect of lowering glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] With 512Kg of measured lactic acid (mass percentage content 88%), dehydrate under vacuum at a temperature of 70-80°C, then add 1Kg of magnesium oxide, and continue to gradually increase the temperature under vacuum to 150-170°C, Carry out polycondensation reaction, stop reaction when water yield is 70-80Kg. Add 95Kg of glycerin, add 0.4Kg of sodium hydroxide, and keep the temperature at about 170°C under vacuum to carry out the esterification reaction until the acid value is less than 2mgKOH / g, then stop the reaction, and the reaction time is about 6 hours. After the reaction, the unreacted glycerin, lactic acid, free polylactic acid and water are distilled off by a thin film evaporator, the distillation temperature is 170-175°C, and the vacuum is 80-150Pa.

[0018] Put 150kg of acetic acid and 450Kg of distilled polylactide glyceride into the reaction kettle again, add 0.5Kg of phosphoric acid, gradually raise the temperature to 130-140°C under vacuum, and carry out th...

Embodiment 2

[0020] Take 800Kg of measured lactic acid (mass percentage 88%), dehydrate under vacuum at a temperature of 70-80°C, then add 1.1kg of calcium oxide, and continue to gradually increase the temperature under vacuum to 150-170°C , carry out polycondensation reaction, and stop the reaction when the water output is 35-40Kg. Add 90Kg of glycerin, add 0.5kg of potassium hydroxide, and keep the temperature at about 170°C under vacuum to carry out the esterification reaction until the acid value is less than 2mgKOH / g, then stop the reaction, and the reaction time is about 5.5 hours. After the reaction, the unreacted glycerin, lactic acid, free polylactic acid and water are distilled off by a thin film evaporator, the distillation temperature is 170-175°C, and the vacuum is 100-150Pa.

[0021] Put 150kg of acetic acid and 240Kg of distilled polylactide glyceride into the reaction kettle again, add 0.5Kg of p-toluenesulfonic acid again, gradually raise the temperature to 130-140°C under...

Embodiment 3

[0023] Take 800Kg of measured lactic acid (mass percentage 88%), dehydrate under vacuum at a temperature of 70-80°C, then add 1.2Kg of magnesium oxide, and continue to gradually increase the temperature under vacuum to 150-170°C , carry out polycondensation reaction, and stop the reaction when the water output is 35-40Kg. Add 90Kg of glycerin, add 0.4Kg of potassium hydroxide, and keep the temperature at about 170°C under vacuum to carry out the esterification reaction until the acid value is less than 2mgKOH / g, then stop the reaction, and the reaction time is about 7 hours. After the reaction, the unreacted glycerin, lactic acid, free polylactic acid and water are distilled off by a thin film evaporator, the distillation temperature is 170-175°C, and the vacuum is 150-250Pa.

[0024] Put 180kg of butyric acid and 240Kg of distilled polylactin glyceride into the reaction kettle respectively, add 0.5Kg of phosphoric acid again, gradually raise the temperature to 130-140°C under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com