A continuous process method for producing methyl silicone oil with various viscosities

A technology of methyl silicone oil and process method, applied in the direction of separation method, chemical instrument and method, filtration separation, etc., can solve the problems that the content of low-molecular substances cannot be guaranteed not to exceed the standard, difficult to control product technical indicators, and low equipment efficiency, etc., to achieve The effect of simple structure, reduced energy consumption, and small space required for equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The continuous process of methyl silicone oil producing a plurality of viscosities, including the following steps:

[0050] (1) 1 ton of the raw material dimethylcycloysiloxane mixture (DMC) and the hexamethiloxane (mm) 350 kg are delivered into the bumper tank according to the mass ratio 1: 2.857, and stir evenly, resulting in a mixture;

[0051] (2) Enter the mixture into the first preheater (steam preheater), and set the temperature of the first preheater to 100 ° C;

[0052] (3) The preheating mixture enters the acidic resin (604 resin) fixed bed reactor by the rotor flow meter, the reaction temperature is 100 ° C, the flow rate is 300 l / hr, the reaction residence time is 0.5 h, and the methyl is obtained. Silicone oil polymer;

[0053] (4) The methyl silicone polymer obtained by step (3) enters the second preheater (silicone oil heater) heating, and the temperature of the first preheater is 140 ° C;

[0054] (5) After the preheating, the methyl silicone polymer is in...

Embodiment 2

[0078] The continuous process method of the production of a plurality of viscosity of the present embodiment is the same as in Example 1.

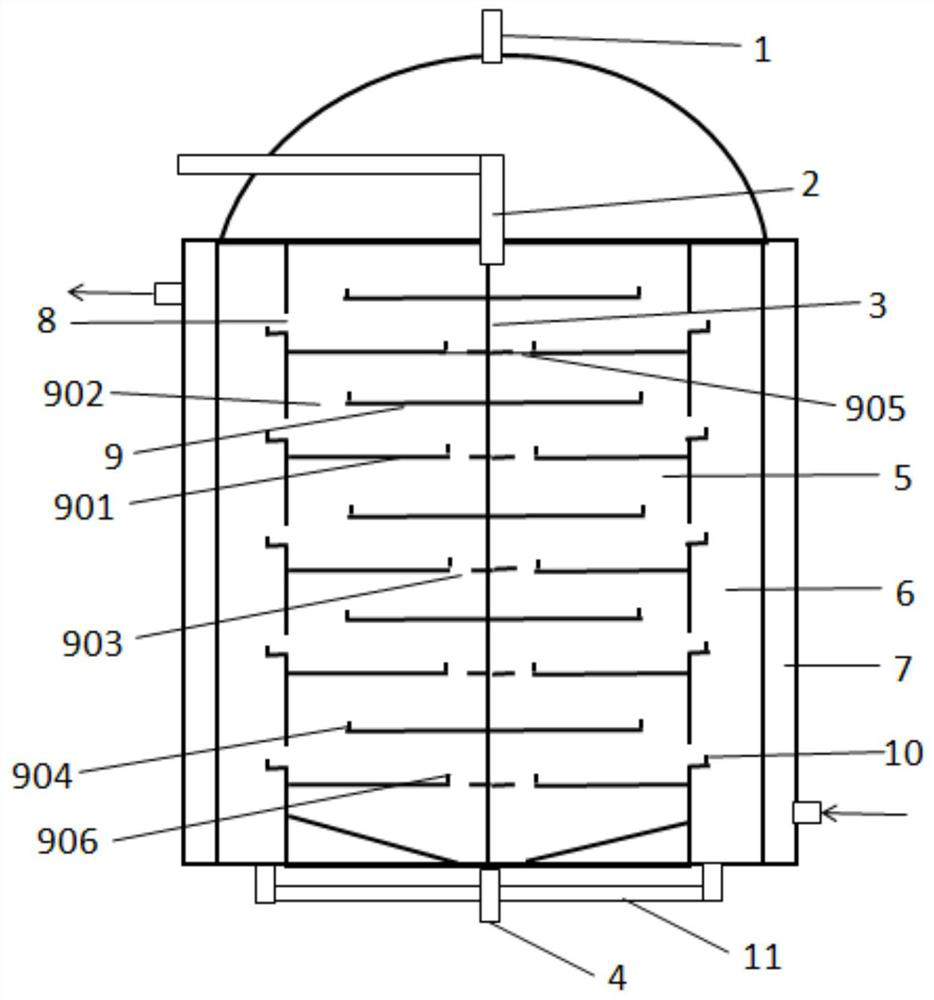

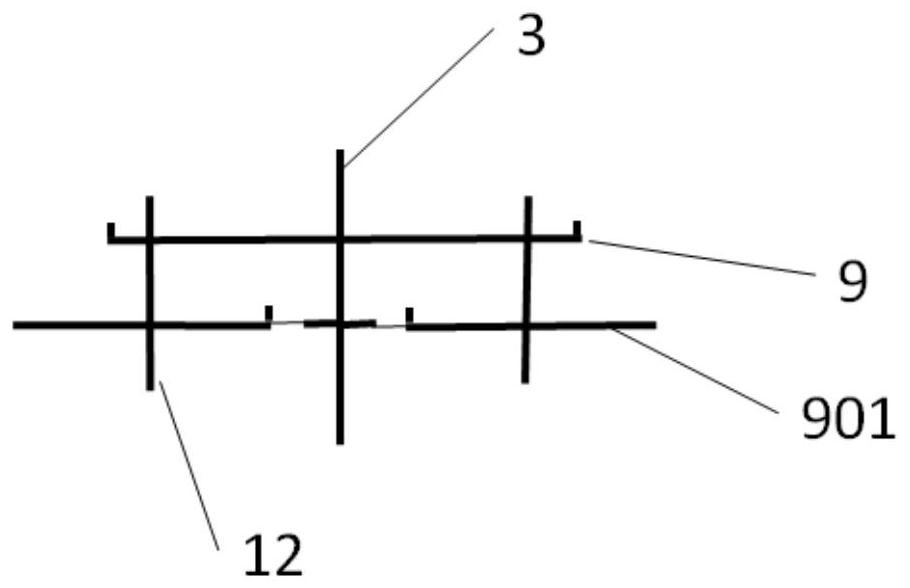

[0079] The multilayer thin film evaporator of the present embodiment, such as figure 2 As shown, the positioning rod 3 penetrates all of the film discs and is only fixed to all of the first thin film discs, and two guide rods 12 are provided around the positioning rod 3, and the guide rod 12 penetrates all of the film discs and only with all of the second thin film disc. The 901 is fixed, and the positioning rod 3 is moved up and down. The spacing of 901. The other structure of the thin film evaporator is the same as in Example 1.

Embodiment 3

[0081] The continuous process method of the production of a plurality of viscosity of the present embodiment is the same as in Example 1.

[0082] The multilayer thin film evaporator of the present embodiment is a vertical thin film evaporator. The top is provided with a steam outlet 1 for discharging a low molecular material; a feed port 2 is provided on the upper side; the inside is provided with a five sets of films. The dish is made such that the methyl silicone polymer can form a continuous liquid film on each group of thin film trays; the spacing of the thin film disc is adjusted by the positioning rod 3 to accommodate a different viscosity methyl silicone polymer; thin film evaporator The bottom is provided with a discharge port 4 for discharging the product. The exterior of the thin film evaporator is provided with a heating jacket, and a high-temperature silicone oil is input in the jacket as a heating source.

[0083] The structure of the positioning rod 3 and the film d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com