Polyimide film, and preparation method and application thereof

A polyimide film and polyimide technology, applied in the field of polymer materials, can solve the problems of high cost, reduce the degree of golden yellow on the surface, and reduce the formation of charge transfer complexes, so as to improve heat resistance and reduce Electron cloud density, effect of increasing thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 274.79925g of DMSO was added to the three-necked flask, and 15.9255g of bis(4-aminocyclohexyl)ether and 16.9740g of 2,2-bis(4-aminophenyl)propane were quickly added to the above-mentioned three-necked flask in an argon atmosphere. 75°C, keep stirring at a rate of 300r / min, slowly add 58.8480g of 3,4,9,10-perylenetetracarboxylic dianhydride within 15 minutes after fully dissolving, then keep stirring for 48 hours to obtain a homogeneous transparent colorless viscous polyamide Acid colloid; take out the colloid and pour it on a clean glass plate, spread it evenly, and then go through the treatment of 80°C for 25min, 200°C for 25min, and 300°C for 25min in the oven; after it is completely cooled, lift it up, and you can get high transparency and durability. High temperature polyimide film. The polyimide repeating structural unit in the polyimide film is:

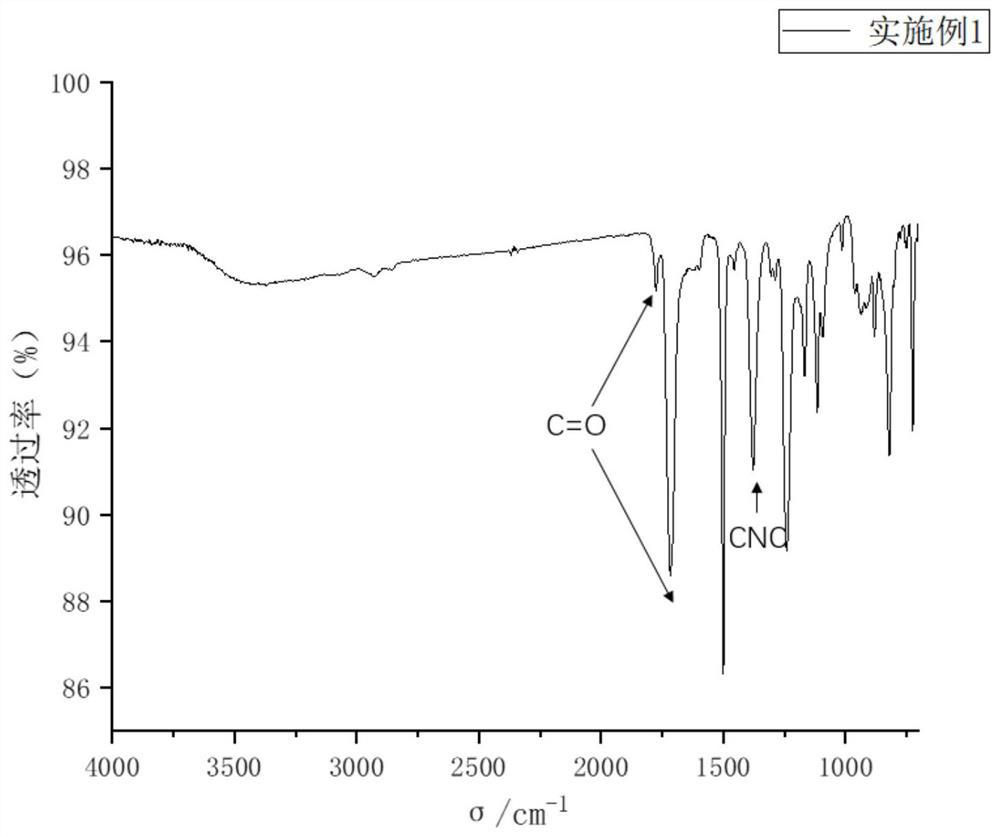

[0062] The infrared spectrogram of the polyimide film prepared in this embodiment is shown in figure 1 .

Embodiment 2

[0064] Add 278.697g of polar aprotic organic solvent DMAC into the three-necked flask, quickly add 31.6400g of 1,5-naphthalene diamine into the above-mentioned three-necked flask in an argon atmosphere, keep stirring at 40°C at a speed of 300r / min, and fully dissolve Slowly add 27.6290 g of 1,4,5,8-decalintetracarboxylic anhydride and 2.0178 g of 5-[2-(1,3-dioxoisobenzofuran-5-yl)prop-2- base] isobenzofuran-1,3-dione, and then continue to stir for 12 hours to obtain a homogeneous transparent colorless viscous polyamic acid colloid; take out the colloid and pour it on a smooth glass plate, coat it evenly, and pass it in the oven for 10 minutes 90°C for 15 minutes, 260°C for 15 minutes, and 360°C for 15 minutes; uncover it after it is completely cooled, and you can get a highly transparent and high-temperature resistant polyimide film. The polyimide repeating structural unit in the polyimide film is:

[0065]

Embodiment 3

[0067] Add 175.8582g of polar aprotic organic solvent DMAC into the three-necked flask, quickly add 24.9912g of 1,5-anthracenediamine into the above-mentioned three-necked flask in an argon atmosphere, and stir continuously at 300r / min at 40°C to fully dissolve Then slowly add 13.4502g 1,2,4,5-cyclohexanetetracarboxylic dianhydride and 20.1780g 5-[2-(1,3-dioxoisobenzofuran-5-yl)propane within 10 minutes -2-yl] isobenzofuran-1,3-dione, followed by continuous stirring for 12 hours to obtain a homogeneous transparent colorless viscous polyamic acid colloid; take out the colloid and pour it on a clean glass plate, coat it evenly, and put it in the oven After 10min of 90°C, 15min of 260°C, and 15min of 360°C in sequence; after complete cooling, the polyimide film with high transparency and high temperature resistance can be obtained. The polyimide repeating structural unit in the polyimide film is:

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com