Preparation method of zinc/carbon nanotube foam composite material

A carbon nanotube and composite material technology, applied in the field of nanomaterials, can solve the problems of reduced cycle stability, inability to achieve 100% DOD charge and discharge, and low cost of zinc metal, and achieve the effect of improving cycle life and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

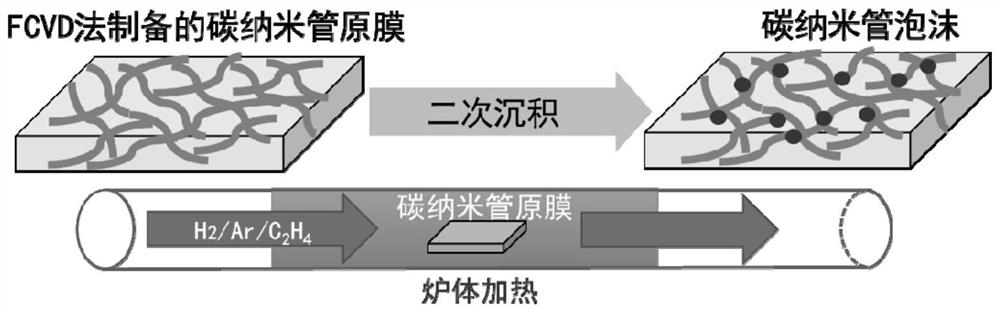

[0068] 1) Preparation of carbon nanotube foam: please refer to figure 1 , place the carbon nanotube film produced by FCVD method in a CVD tube furnace, and pass inert gas such as Ar gas as protective gas and carrier gas, and make the temperature in the reaction chamber follow the rate of 5-10°C / min Raise to 1100~1300°C, then pass Ar, H 2 (Ar:H 2 =0.5~2:1), C 2 h 4 The mixed gas is used for secondary deposition, and the flow rate of the carbon source is controlled to be 40-80 sccm. After 5-40 minutes, the carbon nanotube foam can be obtained by cooling with the furnace, in which H 2 As a carrier gas, it also has the effect of etching amorphous carbon;

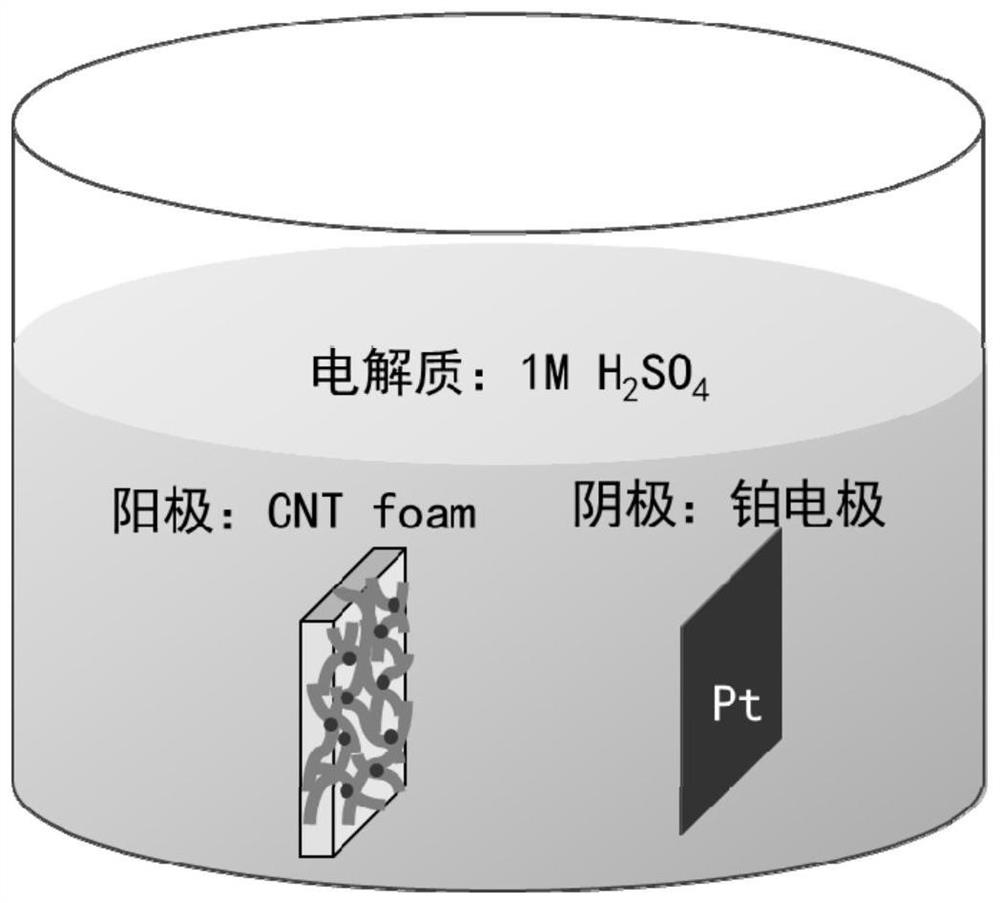

[0069] 2) Configure 1M H 2 SO 4 Solution: Weigh 40g of concentrated sulfuric acid (mass fraction is 98.3%), slowly pour into 200mL of water, stir to dissolve; the concentrated sulfuric acid is diluted and exothermic, after the solution is cooled to room temperature, add water to a total volume of 400mL and then use it;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com