Composite material with low dielectric constant and low dielectric loss and preparation method thereof

A technology of low dielectric constant and composite materials, which is applied in the direction of chemical instruments and methods, other medical devices, synthetic resin layered products, etc., and can solve the needs of high dielectric constant, difficulty in meeting the reliability and miniaturization of electronic integrated devices and other problems, to achieve the effect of improving adhesion, high strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

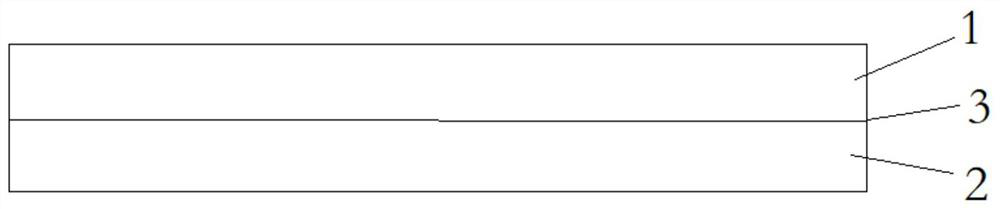

[0053] figure 1 It is a schematic structural diagram of the low dielectric constant and low dielectric loss composite material provided in the embodiment of this application. The low dielectric constant and low dielectric loss composite material is composed of ultra-high molecular weight polyethylene fiber and thermosetting polyolefin resin, including The ultra-high molecular weight polyethylene fiber layer 1 and the thermosetting polyolefin resin layer 2, and the ultra-high molecular weight polyethylene fiber layer 1 and the thermosetting polyolefin resin layer 2 are connected by a chemical bond 3, and the thermosetting polyolefin resin and the ultra-high Molecular weight polyethylene melts to form an interpenetrating network structure.

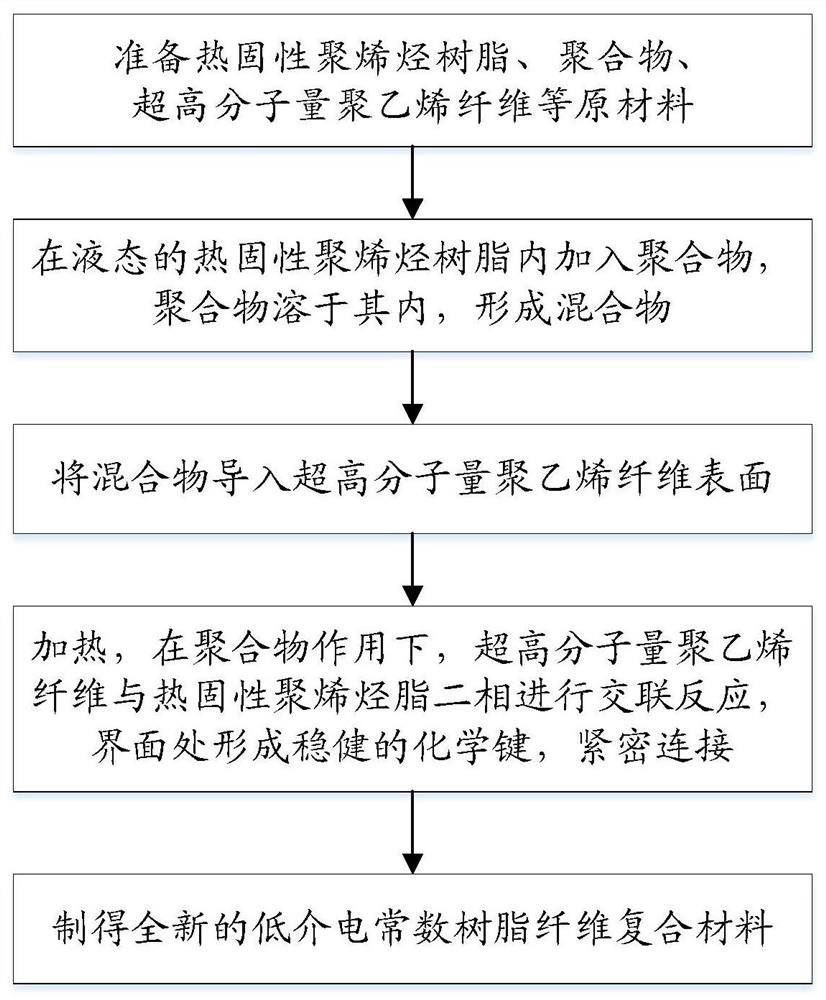

[0054] figure 2 It is a flow chart of the preparation method of the low dielectric constant and low dielectric loss composite material provided in the embodiment of the present application. The steps of the preparation method of the low di...

Embodiment 2

[0062] The embodiment of this application provides a new low dielectric constant and low dielectric loss composite material. The low dielectric constant and low dielectric loss composite material is composed of ultra-high molecular weight polyethylene fibers and thermosetting polyolefin resins, including super The high molecular weight polyethylene fiber layer and the thermosetting polyolefin resin layer, and the ultra-high molecular weight polyethylene fiber layer and the thermosetting polyolefin resin layer are connected by chemical bonds, and the thermosetting polyolefin resin and the ultra-high molecular weight polyethylene are fused to form an interpenetrating network structure.

[0063] The steps of the preparation method of the low dielectric constant and low dielectric loss composite material are as follows:

[0064] The thermosetting polyolefin resin adopts dicyclopentadiene DCPD;

[0065] The coupling agent adopts titanate coupling agent;

[0066] Adding a coupling ...

Embodiment 3

[0071] The embodiment of this application provides a new low dielectric constant and low dielectric loss composite material. The low dielectric constant and low dielectric loss composite material is composed of ultra-high molecular weight polyethylene cloth and thermosetting polyolefin resin, including super The high molecular weight polyethylene cloth layer and the thermosetting polyolefin resin layer are connected by chemical bonds, and the thermosetting polyolefin resin and the ultra high molecular weight polyethylene are fused to form an interpenetrating network structure.

[0072] The steps of the preparation method of the low dielectric constant and low dielectric loss composite material are as follows:

[0073] Thermosetting polyolefin resin adopts tricyclopentadiene TCPD;

[0074] The coupling agent adopts zirconium coupling agent;

[0075] Adding a coupling agent in the liquid thermosetting polyolefin resin, the weight of the coupling agent is 2% of the weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com