Sulfur-doped iron selenide nanorod material, and preparation method and application thereof

An iron selenide, nanorod technology, applied in iron sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of limited performance, limitation, increase synthesis cost and time, etc., to reduce Production cost, low cost, effect of reducing d-orbit overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

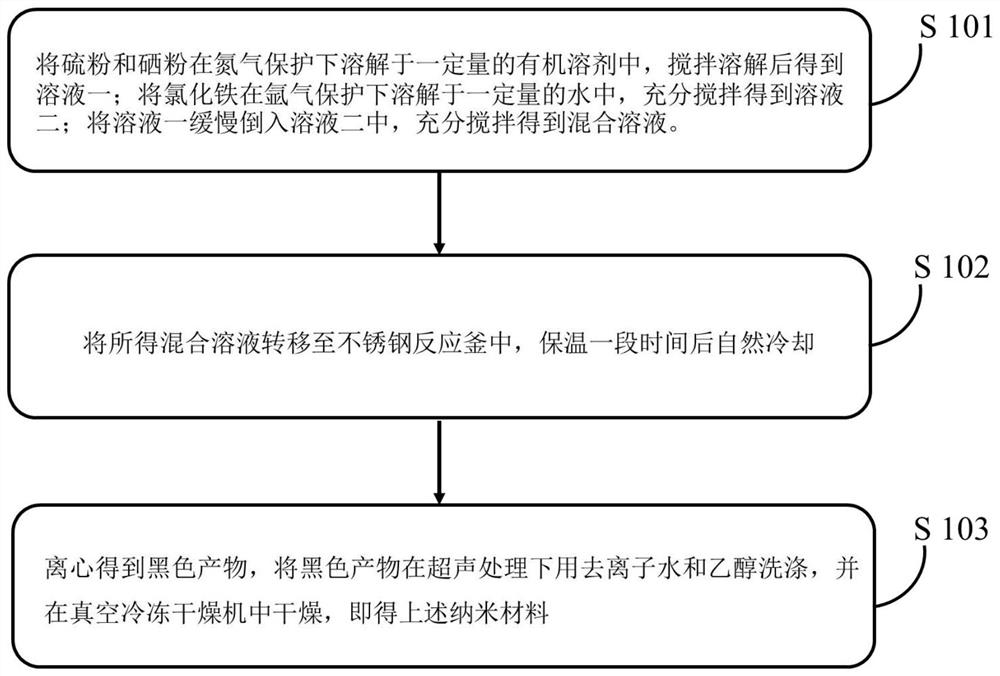

[0030] Aiming at the problems existing in the prior art, the invention provides a preparation method for a sulfur-doped iron selenide nanorod material, comprising the following steps:

[0031] S1, under the protective gas atmosphere, using sulfur powder, selenium powder and soluble iron salt as raw materials, prepare a homogeneous mixed solution;

[0032] S2. Using the homogeneous mixture prepared in S1 at 100-250° C. to prepare a sulfur-doped iron selenide nanorod material through a hydrothermal reaction.

[0033] Among them, the soluble iron salts commonly used at present can all be applicable to the above method. In order to describe the technical solution of the present invention in detail, only ferric chloride is taken as an example. The present invention will be described in detail below in conjunction with the accompanying drawings.

Embodiment 1

[0035] The preparation method of the sulfur-doped iron selenide nanomaterial provided in Example 1 of the present invention comprises the following steps:

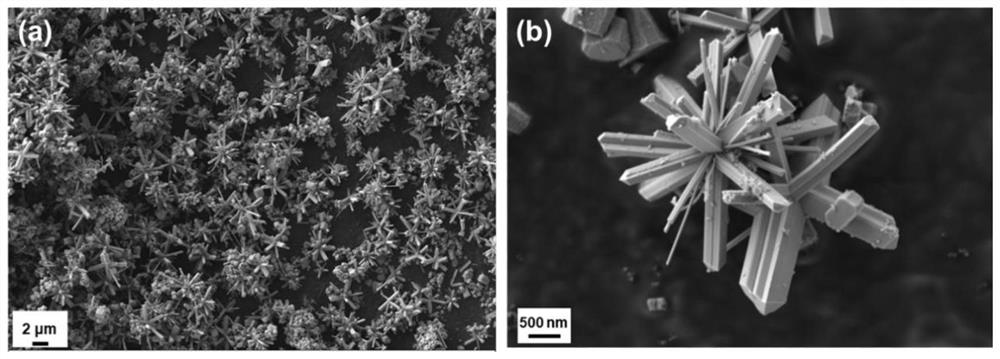

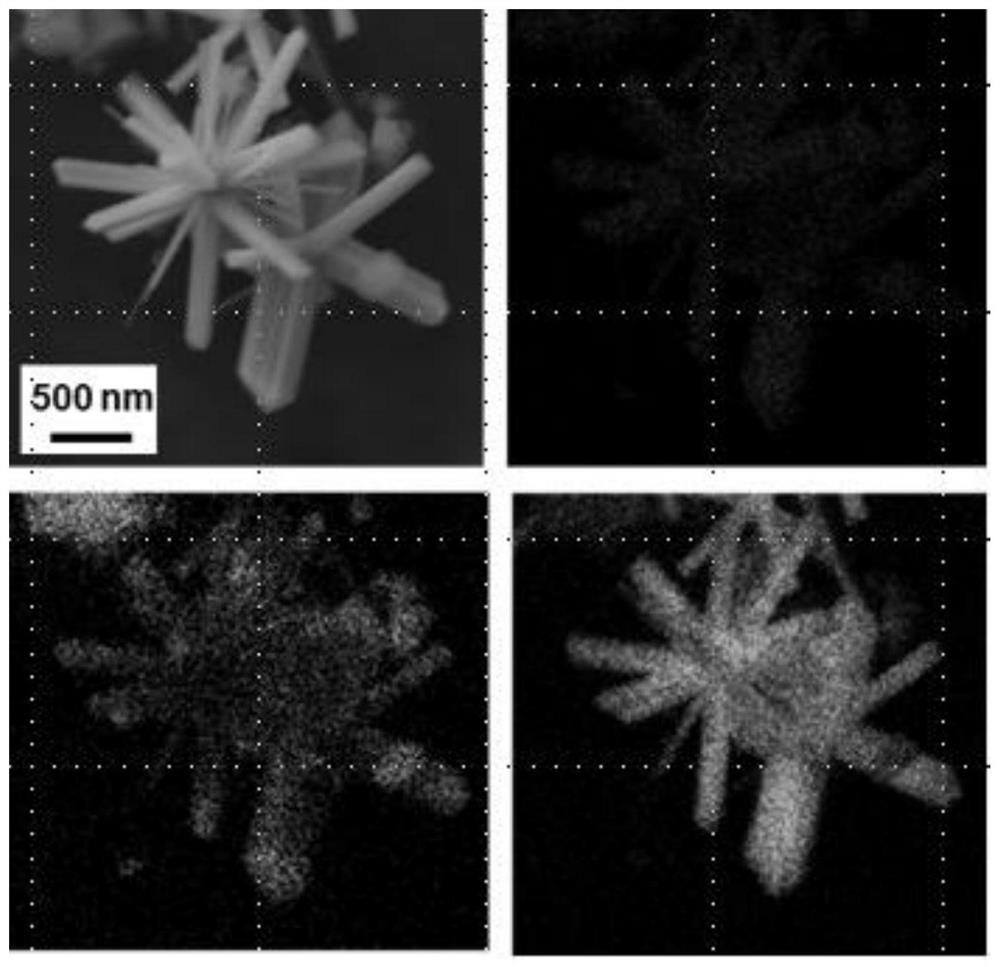

[0036] Such as figure 1 As shown, first, 0.016g of sublimed sulfur powder and 0.118g of selenium powder were dissolved in 8mL of organic solvent under the protection of nitrogen, and fully stirred to form a solution one. Dissolve 0.162g of ferric chloride in 25mL of water under the protection of nitrogen, and fully stir to form solution 2. Slowly pour solution one into solution two to form a mixed solution. Then, the mixed solution was rapidly magnetically stirred at room temperature for 20 minutes, then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 180°C for 24 hours; finally, the temperature of the autoclave was cooled to room temperature , the mixture was centrifuged and washed to obtain a black precipitate, which was ultrasonically dispersed, washed alternately...

Embodiment 2

[0038] The preparation method of the sulfur-doped iron selenide nanomaterial provided in Example 2 of the present invention comprises the following steps:

[0039] Firstly, 0.022g of sublimed sulfur powder and 0.104g of selenium powder were dissolved in 8mL of organic solvent under the protection of nitrogen, and fully stirred to form solution 1. Dissolve 0.162g of ferric chloride in 25mL of water under the protection of nitrogen, and fully stir to form solution 2. Slowly pour solution one into solution two to form a mixed solution. Then, the mixed solution was rapidly magnetically stirred at room temperature for 20 minutes, then the mixture was transferred to a stainless steel autoclave, and the autoclave was placed in an oven at 180°C for 24 hours; finally, the temperature of the autoclave was cooled to room temperature , the mixture was centrifuged and washed to obtain a black precipitate, which was ultrasonically dispersed, washed alternately with absolute ethanol and wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com