A preparation method of flame-retardant water-based polyurethane for impregnation of microfiber base cloth

A water-based polyurethane and base fabric technology, used in textiles and papermaking, can solve the problems of easy migration of flame retardants and poor durability, achieve good toluene resistance synergy, improve poor compatibility, improve solidification rate and foam. The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

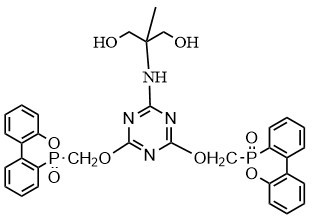

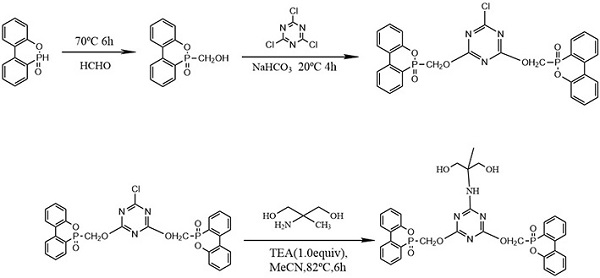

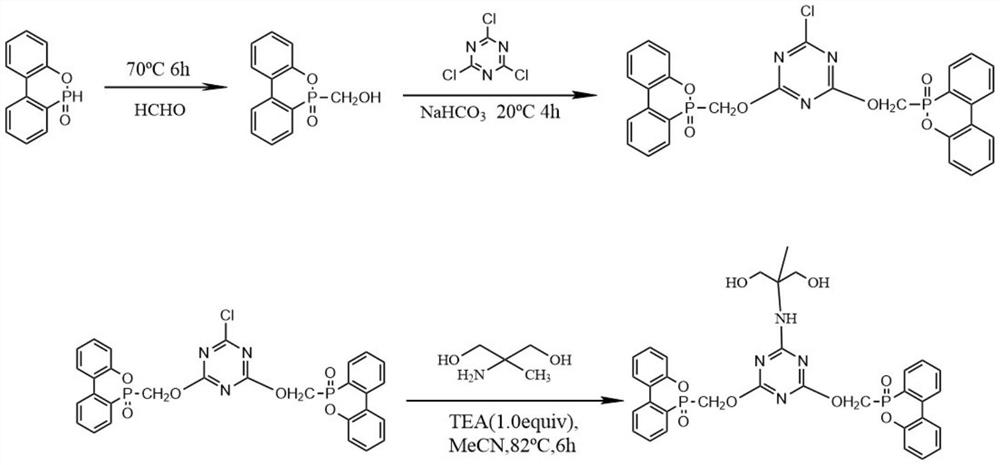

[0023] (1) Preparation of flame retardant chain extender: Dissolve 21.6g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) in ethanol, add 3.1g of formaldehyde dropwise, React at 70°C for 6 hours, wash, filter, and dry the resulting product; then dissolve 18.45g of cyanuric chloride in acetone, add 16.8g of sodium bicarbonate, and then add 24.6g of the product obtained in the previous step, at 20 ℃ for 4 hours, the obtained product was washed, filtered, and dried; the obtained product was added to acetonitrile together with 2-amino-2-methyl-1,3-propanediol, and 13.95 g of triethylamine was added, at 82 ℃ for 6 hours, and then the product was washed, filtered, and dried to obtain the desired flame retardant chain extender.

[0024] (2) Preparation of flame-retardant water-based polyurethane: After dehydrating and drying polybutylene adipate at 120°C under vacuum conditions, 60 parts of polyester polyol, 30 parts of diphenylmethane diisocyanate and 0.01 parts of Orga...

Embodiment 2

[0028] (1) Preparation of flame retardant chain extender: Dissolve 21.6g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) in ethanol, add 3.1g of formaldehyde dropwise, React at 70°C for 6 hours, wash, filter, and dry the resulting product; then dissolve 18.45g of cyanuric chloride in acetone, add 16.8g of sodium bicarbonate, and then add 24.6g of the product obtained in the previous step, at 20 ℃ for 4 hours, the obtained product was washed, filtered, and dried; the obtained product was added to acetonitrile together with 2-amino-2-methyl-1,3-propanediol, and 13.95 g of triethylamine was added, at 82 ℃ for 6 hours, and then the product was washed, filtered, and dried to obtain the desired flame retardant chain extender.

[0029](2) Preparation of flame-retardant water-based polyurethane: After dehydrating and drying polycarbonate diol at 120°C under vacuum conditions, mix 80 parts of polyester polyol, 40 parts of toluene diisocyanate and 0.01 parts of organic bism...

Embodiment 3

[0033] (1) Preparation of flame retardant chain extender: Dissolve 21.6g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) in ethanol, add 3.1g of formaldehyde dropwise, React at 70°C for 6 hours, wash, filter, and dry the resulting product; then dissolve 18.45g of cyanuric chloride in acetone, add 16.8g of sodium bicarbonate, and then add 24.6g of the product obtained in the previous step, at 20 ℃ for 4 hours, the obtained product was washed, filtered, and dried; the obtained product was added to acetonitrile together with 2-amino-2-methyl-1,3-propanediol, and 13.95 g of triethylamine was added, at 82 ℃ for 6 hours, and then the product was washed, filtered, and dried to obtain the desired flame retardant chain extender.

[0034] (2) Preparation of flame-retardant water-based polyurethane: After dehydrating and drying polyethylene adipate at 120°C under vacuum conditions, 100 parts of polyethylene adipate, 50 parts of diphenylmethane diisocyanate and 0.01 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com