Trapping device and method for measuring chloride ions in oil through high-temperature combustion hydrolysis-potentiometric titration

A technology of potentiometric titration and high-temperature combustion, which is applied in the direction of chemical analysis by titration and preparation of test samples, etc. It can solve the problem of whether the oil product is completely burned or not, which affects the chlorine ion capture rate and measurement accuracy. Large and other problems, to achieve the effect of strong practicability, avoiding the influence of color, and high capture degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

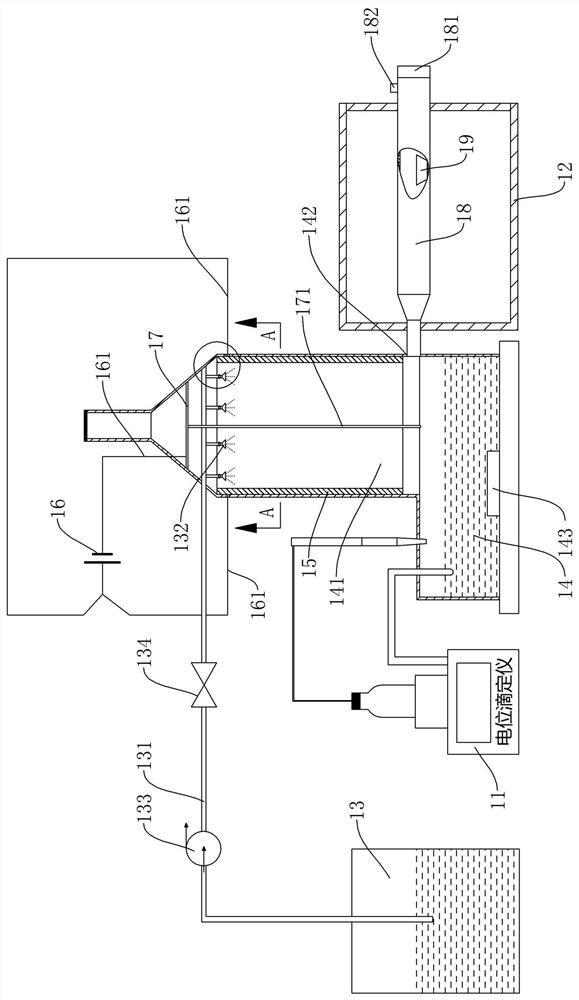

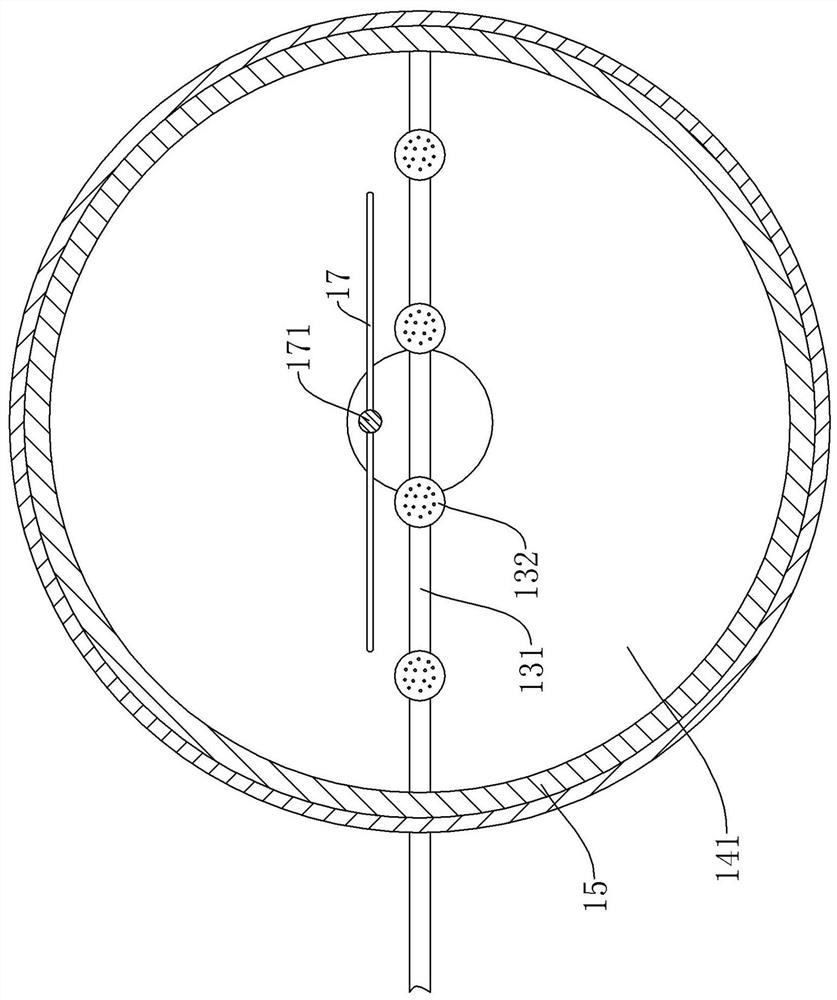

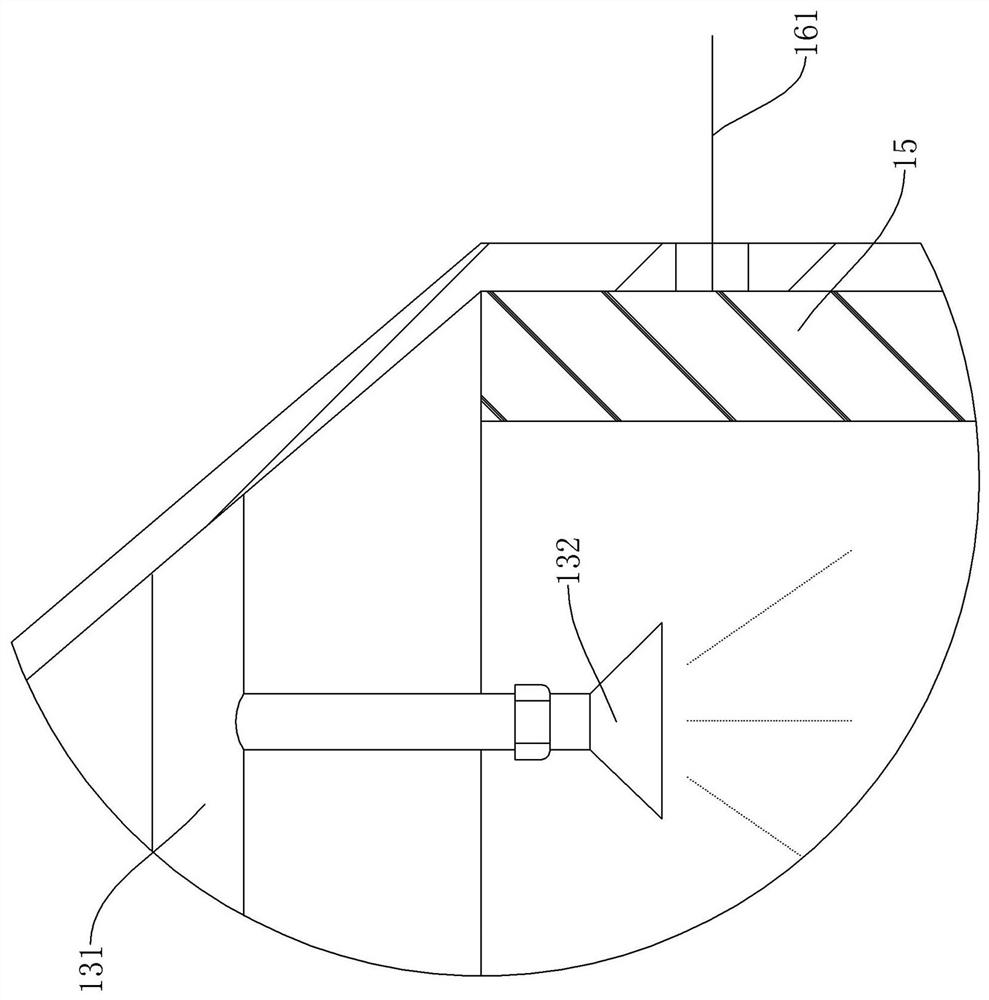

[0057] Embodiment 1, referring to accompanying drawings 1-3, a high-temperature combustion hydrolysis-potentiometric titration trapping device for measuring chloride ions in oil, including a potentiometric titrator arranged outside the absorption pool, a high-temperature furnace, a dosing box, and a potentiometric titrator The burette extends from the upper end into the absorption pool, and the upper end of the absorption pool is provided with an anion accumulation device, which includes a cylindrical plasma chamber connected to the absorption pool on one side of the absorption pool cover, and a matching set in the plasma chamber There is an anode sleeve, the upper end of the anode sleeve is connected to the anode of the power supply through a wire, the upper end of the plasma chamber is fixedly connected with a horizontal support rod, and a vertical cathode rod is arranged in the middle of the support rod, and the upper end of the cathode rod passes through The wire is connect...

Embodiment 2

[0060] Embodiment two, the chlorine content in the standard oil sample is detected, and the accuracy of the method is investigated, and the trapping device is referring to embodiment 1, and the method comprises the following steps:

[0061] (1) Preparation

[0062] Step 1: Follow the attached figure 1 As shown, connect the device and instrument, connect the circuit and gas circuit, check the dosing box, and mix the pre-prepared hydrogen peroxide with a mass concentration of 3% and 10g / L sodium hydroxide solution at a volume ratio of 1:1 to obtain a mixed medicine liquid, add the liquid medicine into the medicine box;

[0063] Step 2: Turn on the switch of the oxygen tube, adjust the oxygen flow rate to 400mL / min, check the airtightness of the instrument, and replace the air with oxygen for 15 minutes after there is no air leakage;

[0064] Step 3: Turn on the high-temperature furnace to heat, gradually raise the temperature to 850°C, and keep the constant temperature at 850°...

Embodiment 3

[0084] Embodiment three: the mensuration of the chlorine content in the anti-fuel oil of a certain power plant specifically comprises the following steps:

[0085] (1) Preparatory work: same as Example 2, no more details.

[0086] (2) Oil sample test:

[0087] The first step: Burn the porcelain boat for the test in a muffle furnace, and use it after burning at 850°C for 30 minutes;

[0088] Step 2: Weigh the oil sample m to be 0.4960g and put it into the porcelain boat;

[0089] Step 3: Push the porcelain boat containing the oil sample into the quartz tube, and tighten the rubber stopper to start the experiment;

[0090] Step 4: Spray the chemical solution in the chemical dosing box into the anode sleeve through the spray device, and adjust the flow rate of the chemical spray pipeline to 10mL / min during the test;

[0091] Step 5: After the oil sample is burned for 25 minutes, stop the oxygen flow, remove the rubber stopper, take out the porcelain boat in the quartz tube, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com