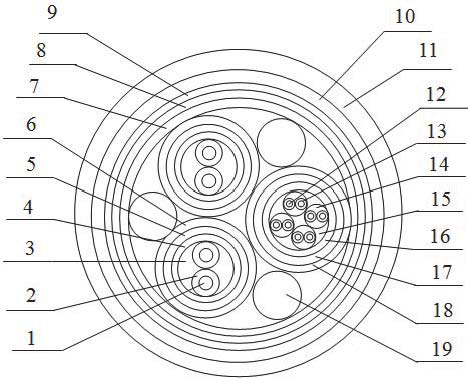

Composite cable for signal and digital network transmission

A digital network and integrated cable technology, applied in insulated cables, cables with double-stranded/quad-stranded, cables, etc., can solve the problems of single signal transmission, not resistant to environmental cracking, etc., to save line space , Avoid secondary wiring, save the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, weighing the raw materials of each component, the components are proportioned by mass percentage as follows: 20 parts of ethylene-vinyl acetate copolymer, 12 parts of polyester elastomer, 5 parts of chlorinated polyethylene, hydrogenated base oil 5 parts, 2 parts of maleic anhydride grafted polyolefin elastomer, 42 parts of halogen-free flame retardant, 8 parts of flame retardant, 0.5 part of alkyl siloxane, 1.5 parts of antioxidant, 4 parts of smoke suppressant, each The sum of the parts by mass of the components is 100 parts.

[0024] Step 2, mixing, put the raw materials of each component weighed in step 1 into an internal mixer, and the mixing temperature is 150-165°C, so that each component is mixed evenly to form a jelly.

[0025] Step 3, granulation, extruding and granulating the product kneaded in step 2. The temperature of each zone of the twin-screw extruder is 102-145° C. to obtain a finished halogen-free low-smoke flame-retardant elastomer outer shea...

Embodiment 2

[0028] Step 1, weighing each component raw material, its component ratio by mass percentage is: ethylene-vinyl acetate copolymer 15 parts, polyester elastomer 15 parts, chlorinated polyethylene 4 parts, hydrogenated base oil 5 parts , 2 parts of maleic anhydride grafted polyolefin elastomer, 45 parts of halogen-free flame retardant, 8 parts of flame retardant, 0.5 part of alkyl siloxane, 1.5 parts of antioxidant, 4 parts of smoke suppressant, each component The sum of the mass percentage parts is 100 parts. All the other steps are the same as in Example 1.

[0029] The test results of the main items of the halogen-free low-smoke flame-retardant elastomer outer sheath of the present invention are shown in Table 1. It can be seen from the table that the test results of the outer sheath in the application scheme of the present invention are very good and meet the requirements of this product. The environment-friendly requirements of low-smoke, halogen-free, flame-retardant, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com