Plug pin type soft tissue repair patch and preparation method thereof

A soft tissue and plug-in technology, applied in medical science, muscles, ligaments, etc., can solve the problems of immune rejection, cytotoxicity, low biological activity, etc., and achieve the effect of avoiding re-tearing, high healing strength, and strong holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the other hand, the method for preparing the plug-in soft tissue repair patch includes the following steps:

[0041] Step 1: Weaving the electrospun composite material with highly imitated tendon fibers into a rectangular sheet-like structure, and dividing the rectangular sheet-like structure into a sheet-like part and a double-column part according to the length ratio;

[0042] Step 2: Apply artificial osteoinductive material evenly on the surface of the double columnar part, and then cut the double columnar part into two symmetrical parts;

[0043] Step 3, use the tendon wire to lock the above two parts along the cut gap, and then roll them to both sides to form a columnar structure.

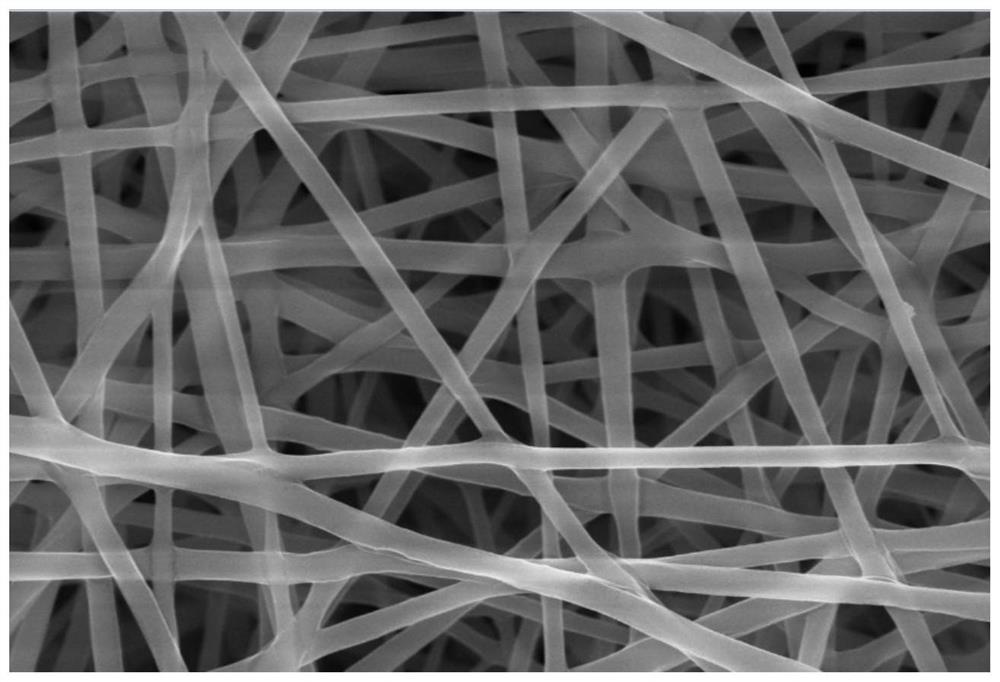

[0044] In a preferred embodiment of the present invention, step 1 will use decellularized dermal matrix, collagen, silk fibroin, polypropylene, polyethylene, polylactic acid, polyglycolic acid, polycaprolactone, chitosan, etc. One or several mixed solutions are spun into a rectangu...

Embodiment 1

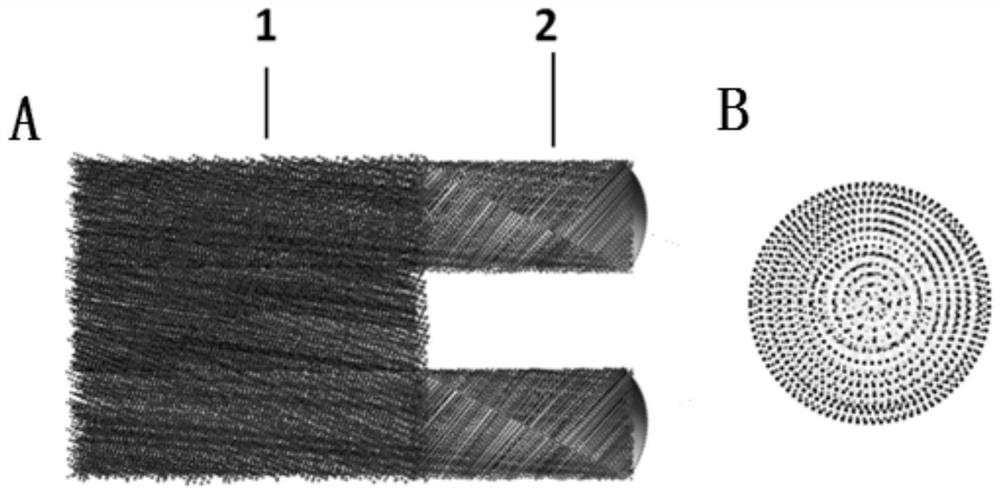

[0050] This embodiment provides a plug-type soft tissue repair patch, the main structure of which is a plug-type segmented structure, including a sheet-shaped part 1 and a double-column part 2 .

[0051] Among them, the sheet-like part 1 is a rectangular sheet-like structure with a thickness of about 1.5mm, which is made of acellular dermal matrix, collagen, silk fibroin, polypropylene, polyethylene, polylactic acid, polyglycolic acid, polycaprolactone , chitosan and other mixed solutions of one or more of them are woven by electrospinning technology, have certain mechanical strength, and are mainly used to bridge the tendon of the rotator cuff;

[0052] The double columnar part 2 is composed of two symmetrical columnar structures connected to one end of the sheet part 1, and is mainly used for anchoring in the bone tunnel part; it is made of acellular dermal matrix, collagen, silk fibroin, polypropylene, polypropylene A sheet-like composite material and heterogeneous (body) a...

Embodiment 2

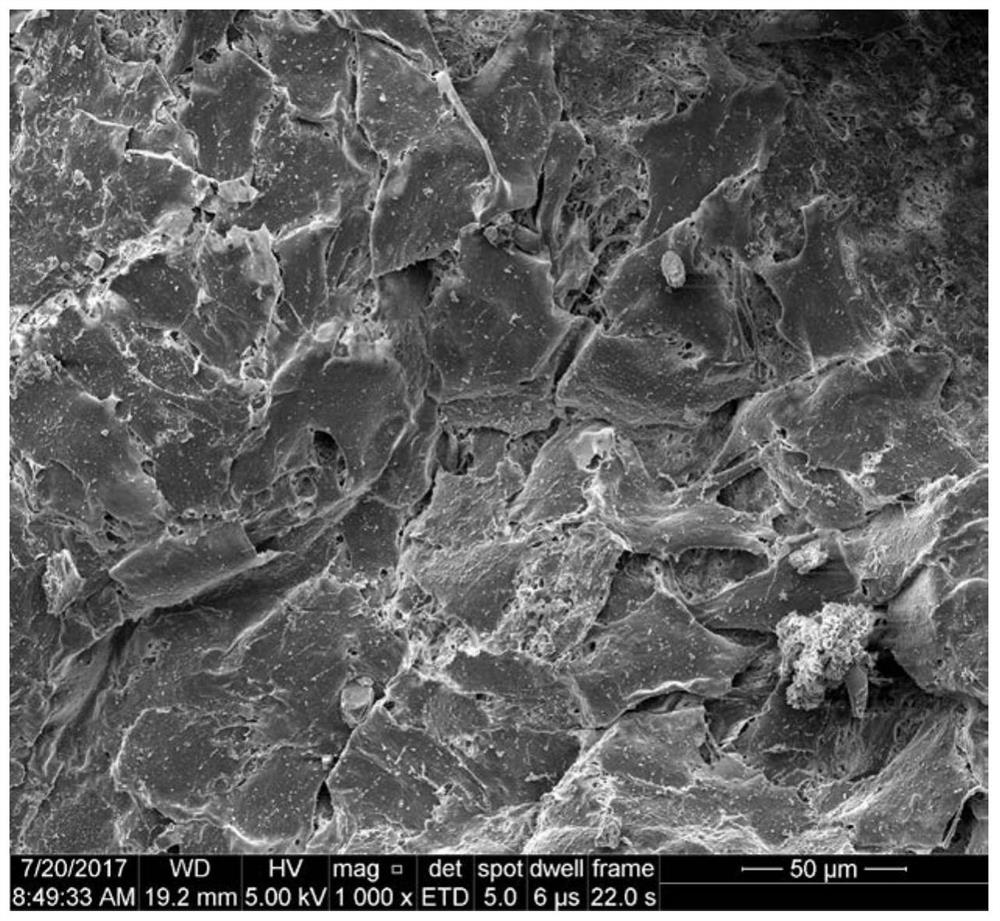

[0064] In vitro osteoblast experiments on the cross-section of the double-column part of the plug-in soft tissue repair patch provided in Example 1:

[0065] Osteoblasts were co-cultured with plug-in soft tissue repair patch on the cross-section of the double columnar structure for 14 days, and alizarin staining was performed, as shown in Figure 4 As shown, the columnar part significantly promotes the mineralization of osteoblasts, which is conducive to the integration of tendon and bone after being pulled into the bone canal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com