Preparation method of novel carbon-based material loaded transition metal monatomic catalyst

A carbon-based material, transition metal technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of enriching methods, improving activation efficiency, and improving loading and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

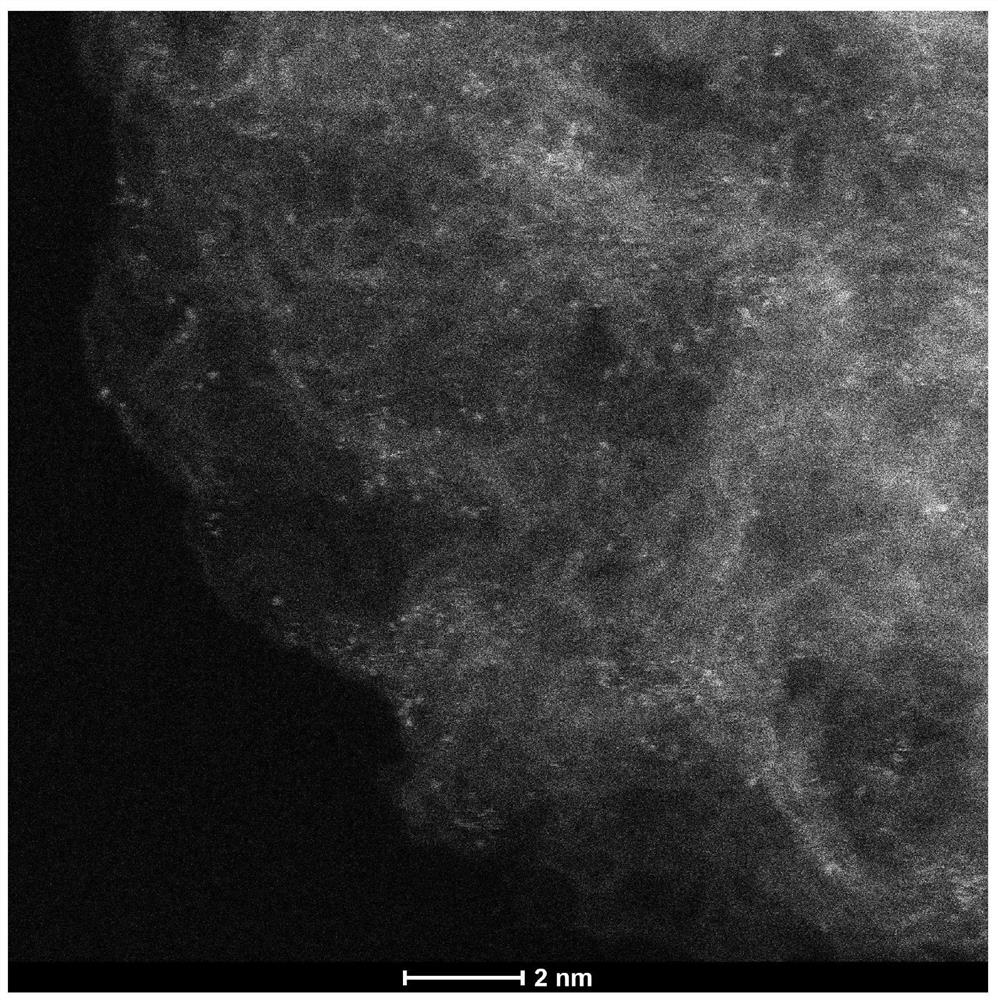

Image

Examples

Embodiment 1

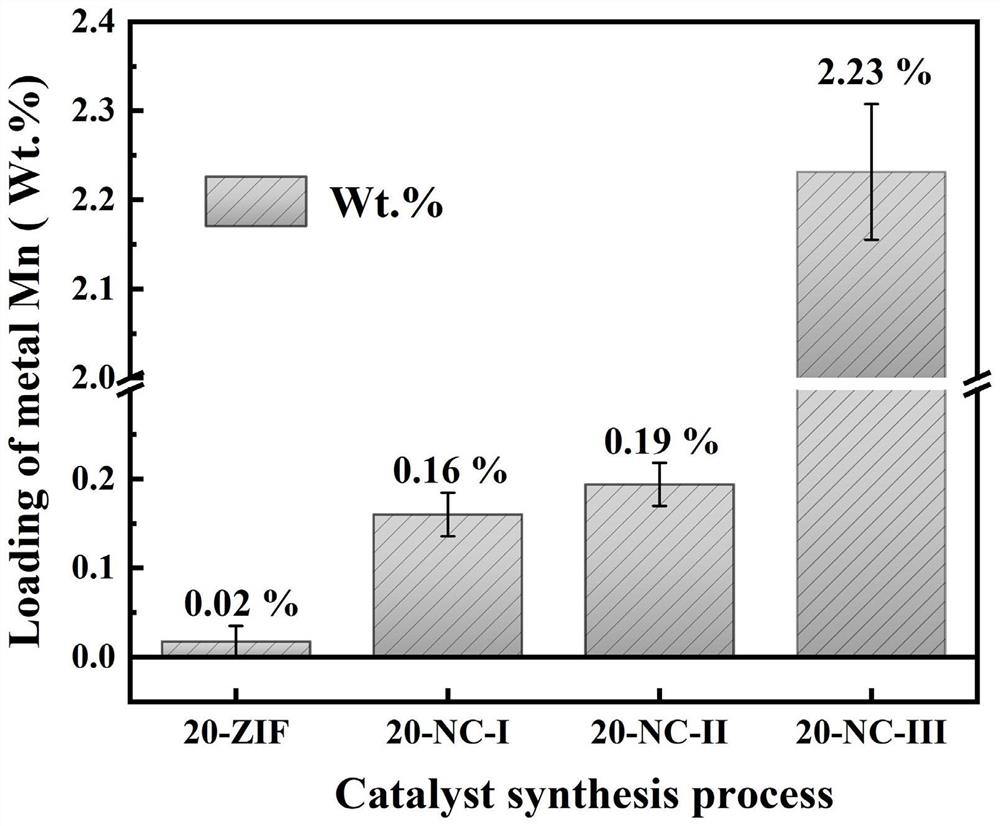

[0036] Example 1: Preparation of a new carbon-based material-supported manganese single-atom catalyst 20%Mn-NC-Ⅲ

[0037] 1) 2.3799g Zn(NO 3 ) 2 ·6H 2 O and 0.5362g (CH 3 COO)3Mn·2H 2 O was dissolved in DMF solution to form solution A.

[0038] 2) Dissolve 1.3136g of 2-methylimidazole in DMF solution to form solution B.

[0039] 3) Mix solution A in 1) and solution B in 2), and keep warm at 120° C. for 24 hours.

[0040]4) After the suspension in 3) was cooled at room temperature, it was collected by centrifugation at 8000 rpm, washed 3 times with ethanol (10000 rpm, 12000 rpm, 14000 r / min), and vacuum-dried at 60°C for 5 hours to obtain the precursor 20% Mn-ZIF -8.

[0041] 5) Mn-ZIF-8 obtained in 4) in N 2 Calcined in the atmosphere, the heating rate is 5°C / min below 1000°C, the heating rate is 2°C / min above 1000°C, the constant temperature calcination temperature is 1100°C, and the constant temperature calcination time is 1h. 20% Mn-NC-I was obtained.

[0042] 6) ...

Embodiment 2

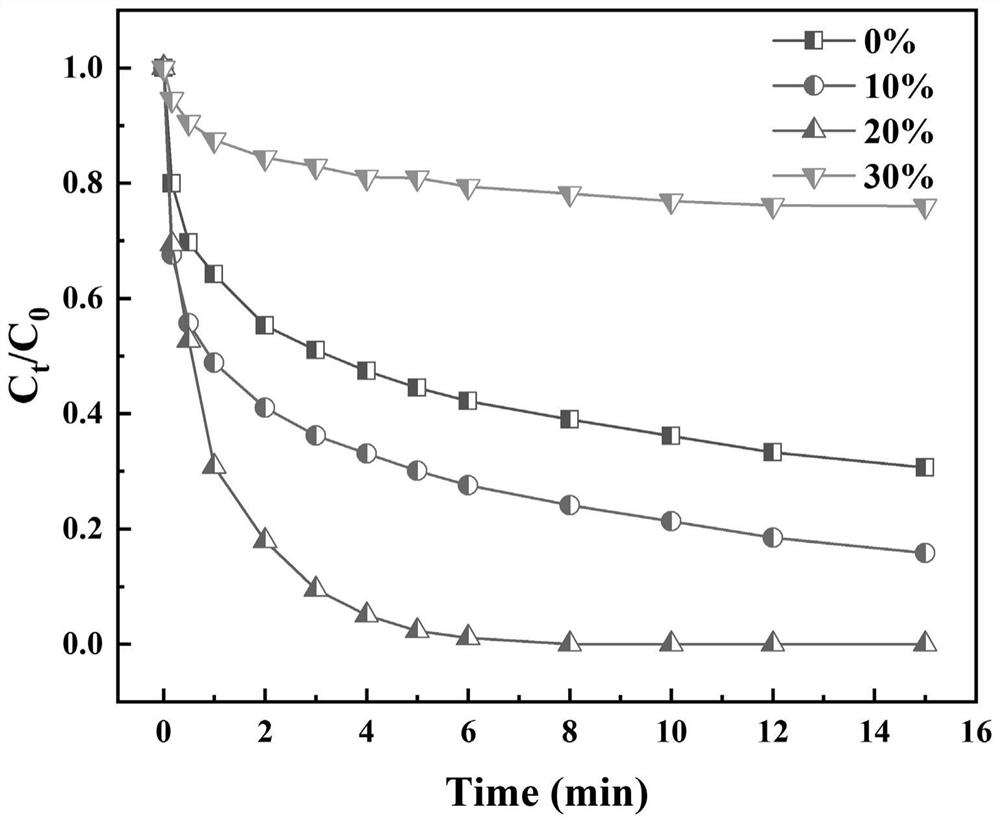

[0049] Example 2: Novel carbon 20% Mn-NC-Ⅲ catalyst activates persulfate to degrade phenolic compounds

[0050] In order to investigate the degradation effect of the new carbon 20% Mn-NC-Ⅲ catalyst on phenolic compounds, a representative phenol (Phenol) was selected as the target organic compound. Prepare 10mmol L with deionized water -1 Phenol stock solution, 30mmol L -1 Potassium persulfate (PMS) stock solution and 0.2mol L -1 Boric acid / borax buffer solution (pH 7.2); add 5mL Phenol stock solution, 5mL PMS stock solution, 12.5mL buffer solution, and 27.5mL deionized water quantitatively according to the 50mL system, where Phenol and PMS are placed separately before starting the reaction, and the reaction is adjusted separately The pH of the system is to 7.2, and the temperature of the reaction system is well controlled; 0.005g of the catalyst to be tested is added to the Phenol part of the reaction system, the PMS part is quickly poured into it and mixed, and the timing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com