Preparation method of anti-ammonium bisulfate flat plate type denitration catalyst and obtained catalyst

A technology of denitrification catalyst and ammonium bisulfate, which is applied in the field of selective catalytic reduction catalyst, which can solve the problems of poor catalyst wear resistance, reduced denitrification activity, and weak stability, and achieve low conversion rate and reduce the formation of ammonium bisulfate , Reduce the effect of ammonium bisulfate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

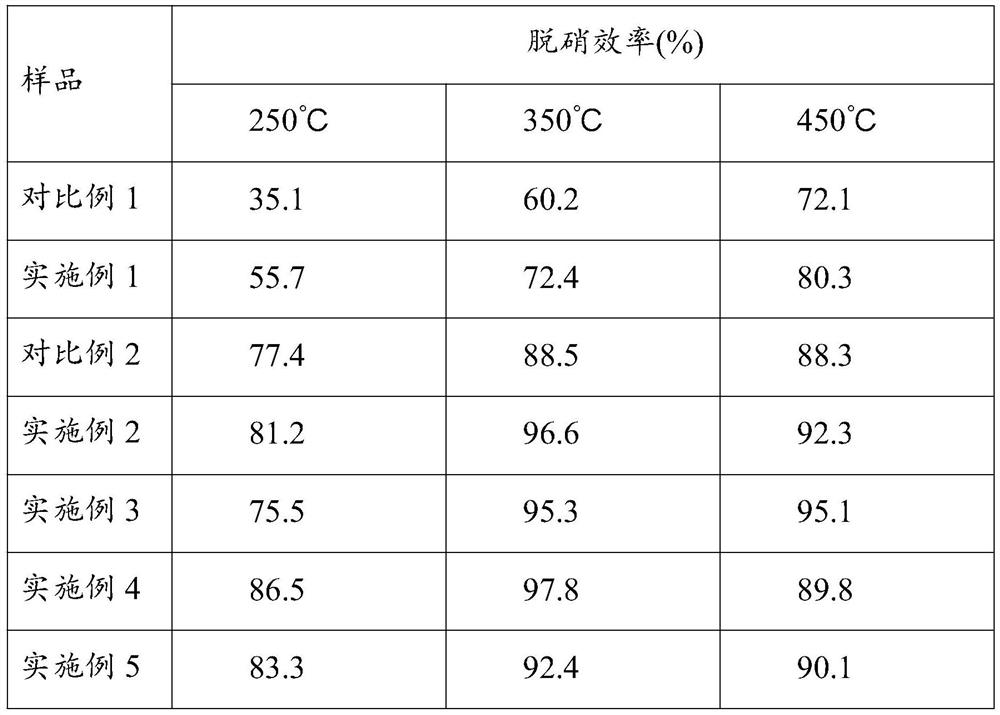

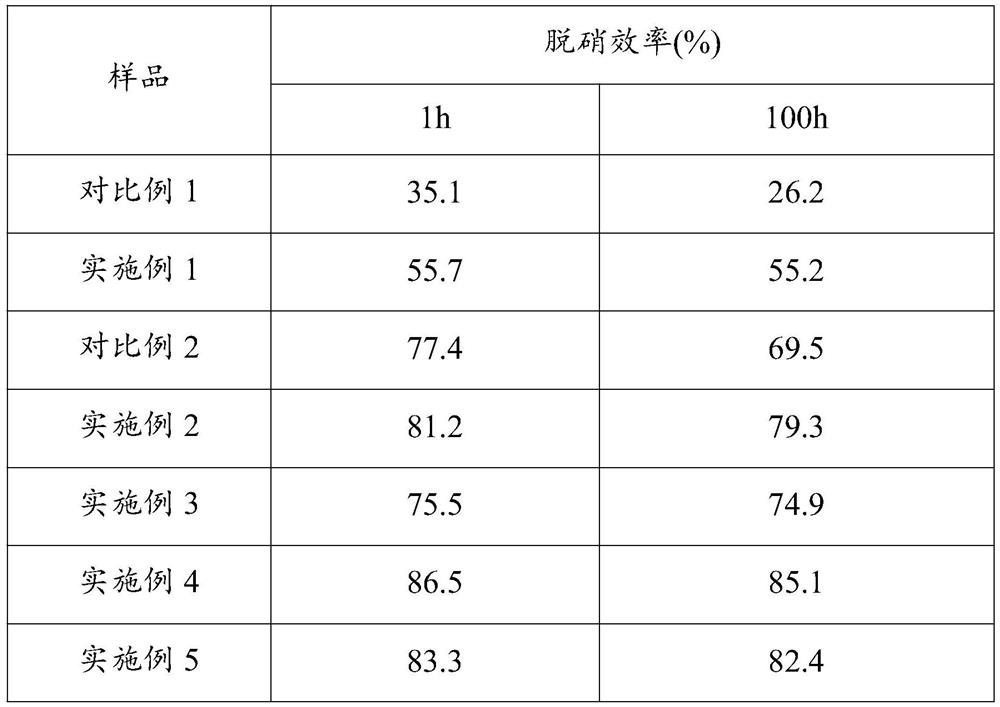

Examples

Embodiment 1

[0031]A kind of preparation method of anti-ammonium bisulfate plate type denitration catalyst, comprises the following steps:

[0032] ① Weigh anatase TiO according to the mass ratio of 8:2 2 , high-silicon ZSM-5 molecular sieve, placed in the mixing tank, add deionized water, attapulgite, hydroxypropyl cellulose and glass fiber in turn, wherein, SiO in the high-silicon ZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio is greater than 400, and the amount of attapulgite added is anatase TiO 2 And 1% of the total mass of high silicon ZSM-5 molecular sieve, hydroxypropyl cellulose is anatase TiO 2 and 1% of the total mass of high-silicon ZSM-5 molecular sieve, the amount of glass fiber added is anatase TiO 2 and 1% of the total mass of high-silicon ZSM-5 molecular sieves, kneaded for 2 hours to prepare a denitration catalyst paste;

[0033] ②Use a roller to coat the catalyst paste on the stainless steel mesh, and after punching, crimping, and drying, calcinate at 550°C for 5...

Embodiment 2

[0044] A kind of preparation method of anti-ammonium bisulfate plate type denitration catalyst, comprises the following steps:

[0045] ① Weigh anatase TiO according to the mass ratio of 9:1 2 , high silicon ZSM-5 molecular sieve, placed in the mixing tank, add deionized water, diatomaceous earth, hydroxymethyl cellulose and glass fiber successively, wherein, SiO in the high silicon ZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio is greater than 400, and the amount of diatomaceous earth added is anatase TiO 2 and 2% of the total mass of high silica ZSM-5 molecular sieve, hydroxymethyl cellulose is anatase TiO 2 and 2% of the total mass of high silicon ZSM-5 molecular sieve, the amount of glass fiber added is anatase TiO 2 and 2% of the total mass of high-silicon ZSM-5 molecular sieves, kneaded for 3 hours to obtain a denitration catalyst paste;

[0046] ②Use a roller to coat the catalyst paste on the stainless steel mesh, after punching, crimping, and drying, calcinate ...

Embodiment 3

[0057] A kind of preparation method of anti-ammonium bisulfate plate type denitration catalyst, comprises the following steps:

[0058] ① Weigh anatase TiO according to the mass ratio of 8.5:1.5 2 , high-silicon ZSM-5 molecular sieve, placed in the mixing tank, add deionized water, sepiolite, safflower powder and glass fiber successively, wherein, SiO in the high-silicon ZSM-5 molecular sieve 2 / Al 2 o 3 The molar ratio is greater than 400, and the amount of sepiolite added is anatase TiO 2 and 5% of the total mass of high-silicon ZSM-5 molecular sieves, the scallop powder is anatase TiO 2 and 2.5% of the total mass of high-silicon ZSM-5 molecular sieve, the amount of glass fiber added is anatase TiO 2 and 3% of the total mass of high-silicon ZSM-5 molecular sieves, and kneaded for 1 hour to obtain a denitration catalyst paste;

[0059] ②Use a roller to coat the catalyst paste on the stainless steel mesh, after punching, crimping, and drying, calcinate at 600°C for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com