Preparation method of nickel tungsten phosphide-nickel tungsten oxide with heterostructure

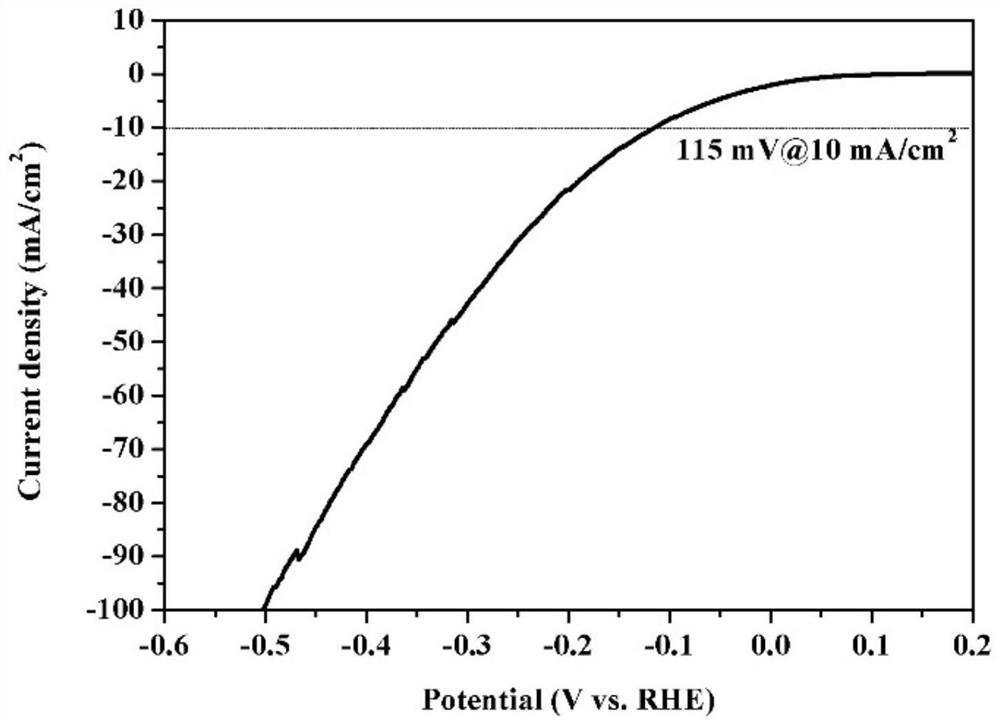

A technology of nickel-tungsten oxide and heterostructure, applied in phosphides, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of limited active surface area, poor stability, poor conductivity, etc., and achieve abundant reserves and high-quality products The effect of uniform shape distribution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

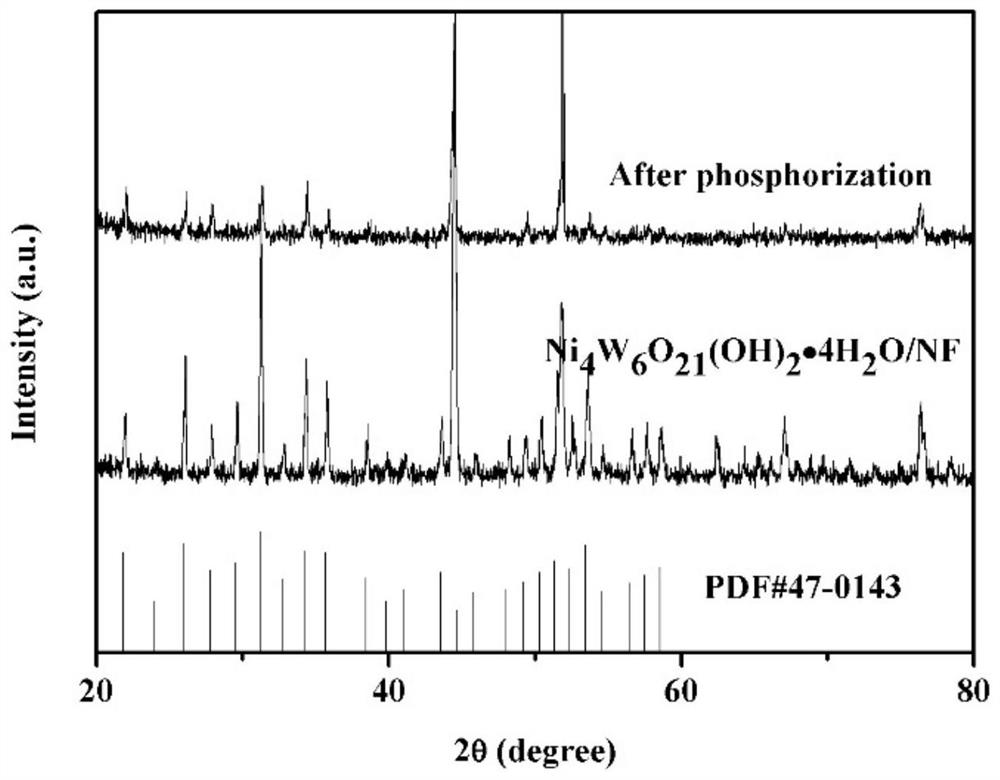

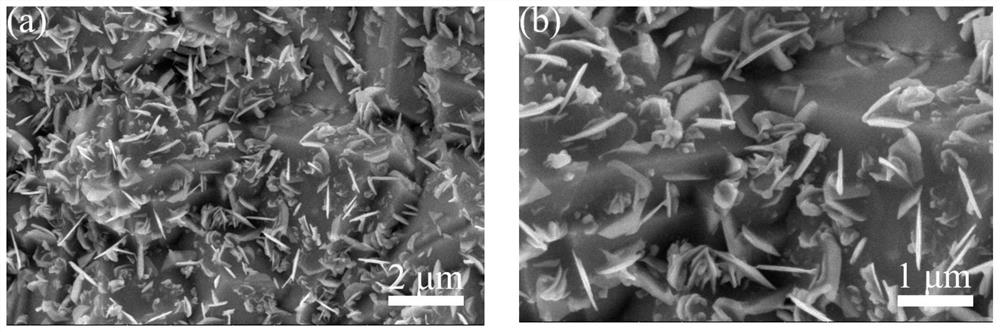

Embodiment 1

[0029] ⑴Cut NF into 2×3cm 2 The small pieces were ultrasonically cleaned in 3M concentrated hydrochloric acid for 20 min to remove oxides on the surface of NF; after that, they were washed three times with absolute ethanol and deionized water.

[0030] (2) Weigh a certain mass of Ni(NO 3 ) 2 ·6H 2 O and (NH 4 ) 6 h 2 W 12 o 40 ·nH 2 O was added to deionized water at the same time to prepare a mixed solution, wherein the molar ratio of Ni:W was controlled to be 1:3, the concentration of nickel source was 0.016mol / L, and the concentration of tungsten source was 0.0042mol / L, and ultrasonically mixed at room temperature After 20 min, a clear blue solution A was obtained.

[0031] (3) Put the NF treated in step (1) at an angle of 45° into the inner lining of the reaction kettle made of polytetrafluoroethylene for sealing, then put the inner lining into a stainless steel outer kettle to fix, and finally place the outer kettle in an electric blast In a dry box, hydrothermal...

Embodiment 2

[0035] ⑴Cut NF into 2×3cm 2 The small pieces were ultrasonically cleaned in 2M concentrated hydrochloric acid for 25 min to remove oxides on the surface of NF; after that, they were washed 4 times with absolute ethanol and deionized water respectively.

[0036] (2) Weigh a certain mass of Ni(NO 3 ) 2 ·6H 2 O and (NH 4 ) 6 h 2 W 12 o 40 ·nH 2 O was added to 30ml deionized water at the same time to prepare a mixed solution, wherein the molar ratio of Ni:W was controlled to be 3:1, the concentration of nickel source was 0.05mol / L, and the concentration of tungsten source was 0.0014mol / L. After mixing for 25 min, a clear blue solution A was obtained.

[0037] (3) Put the NF treated in step (1) at an angle of 55° into the lining of the reaction kettle made of polytetrafluoroethylene to seal, then put the inner lining into a stainless steel outer kettle to fix, and finally place the outer kettle in an electric blast In a dry box, hydrothermal reaction was carried out at 19...

Embodiment 3

[0041] ⑴Cut NF into 2×3cm 2 The small piece was ultrasonically cleaned in 4M concentrated hydrochloric acid for 30 min to remove oxides on the surface of NF; after that, it was washed 5 times with absolute ethanol and deionized water respectively.

[0042] (2) Weigh a certain mass of Ni(NO 3 ) 2 ·6H 2 O and (NH 4 ) 6 h 2 W 12 o 40 ·nH 2 O was added to 30ml deionized water at the same time to prepare a mixed solution, wherein the molar ratio of Ni:W was controlled to be 1:1, the concentration of nickel source was 0.03mol / L, and the concentration of tungsten source was 0.0028mol / L. After mixing for 15 min, a clear blue solution A was obtained.

[0043] (3) Put the NF processed in step (1) at an angle of 65° into the inner lining of the reaction kettle made of polytetrafluoroethylene for sealing, then put the inner lining into a stainless steel outer kettle to fix, and finally place the outer kettle in an electric blast In a drying oven, hydrothermal reaction was carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com