Preparation process of luminous ceramic tile and luminous ceramic tile thereof

A preparation process and ceramic tile technology, which is applied in the field of ceramic tile production, can solve problems such as short afterglow time, single luminous color, and low luminous intensity, and achieve the effects of increasing luminous intensity, solving single color, and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation process of luminescent ceramic tiles, comprising the following specific steps:

[0034] S1) Weigh SrCO respectively according to the formula 3 , CaCO 3 、BaCO 3 , Li 2 CO 3 、Al 2 o 3 , Ga 2 o 3 , SiO 2 、Eu 2 o 3 , boric acid and ethanol are mixed and ground evenly to obtain luminescent powder;

[0035] S2) Mix sodium silicate, absolute ethanol and distilled water in proportion, then add dilute nitric acid dropwise to adjust the pH value, stir evenly with a magnetic heating stirrer, age until transparent, and obtain a sol;

[0036] S3) adding the luminescent powder into the sol while stirring, and then continuing to stir evenly and then drying to obtain luminescent powder sol particles;

[0037] S4) Weigh potassium feldspar, quartz, calcium oxide, borax, zinc oxide and magnesium oxide respectively according to the formula, and mix them uniformly to prepare a glaze; mix the glaze and the luminescent powder sol particles uniformly in proportion, an...

Embodiment

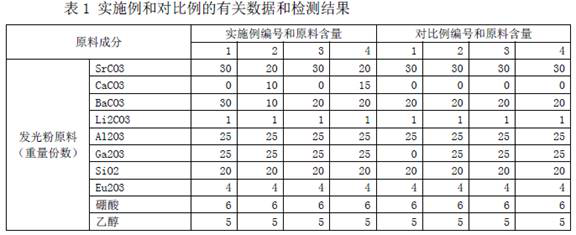

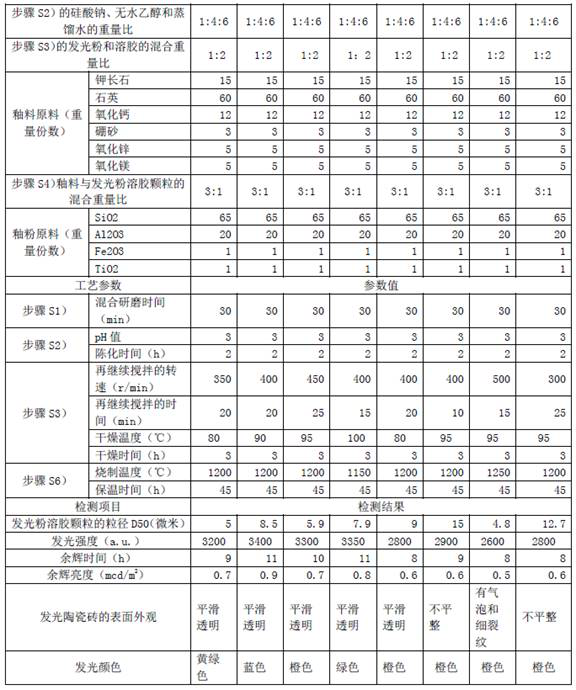

[0065] According to the corresponding preparation of each raw material listed in Table 1 below, and prepare the luminous ceramic tiles of Examples 1-4 and Comparative Examples 1-4 respectively according to the process parameters listed in Table 1 and the following steps:

[0066] S1) Weigh SrCO respectively according to the formula 3 , CaCO 3 、BaCO 3 , Li 2 CO 3 、Al 2 o 3 , Ga 2 o 3 , SiO 2 、Eu 2 o 3 , boric acid and ethanol are mixed and ground evenly to obtain luminescent powder;

[0067] S2) Mix sodium silicate, absolute ethanol and distilled water in proportion, then add dilute nitric acid dropwise to adjust the pH value, stir evenly with a magnetic heating stirrer, age until transparent, and obtain a sol;

[0068] S3) adding the luminescent powder into the sol while stirring, and then continuing to stir evenly and then drying to obtain luminescent powder sol particles;

[0069] S4) Weigh potassium feldspar, quartz, calcium oxide, borax, zinc oxide and magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com