Alicyclic epoxy resin injection material for composite insulator low-temperature-resistant hard sheath and preparation method thereof

A composite insulator and epoxy resin technology, applied in the field of shed materials, can solve the problems of easy cracking of the insulator sheath, and achieve the effect of not easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

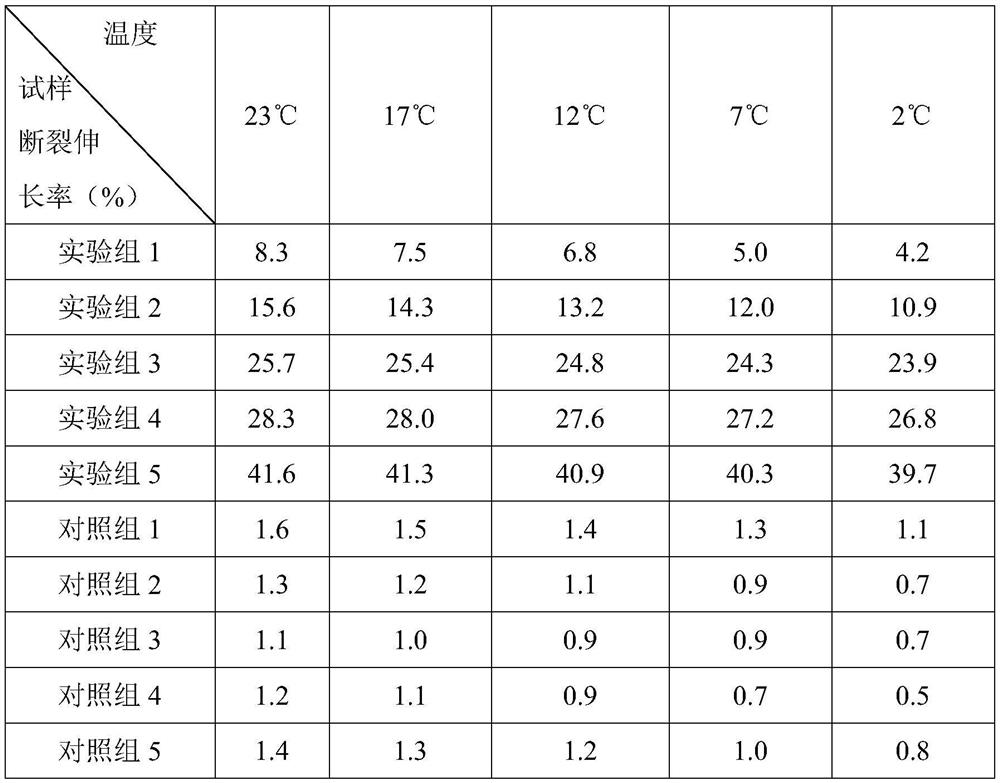

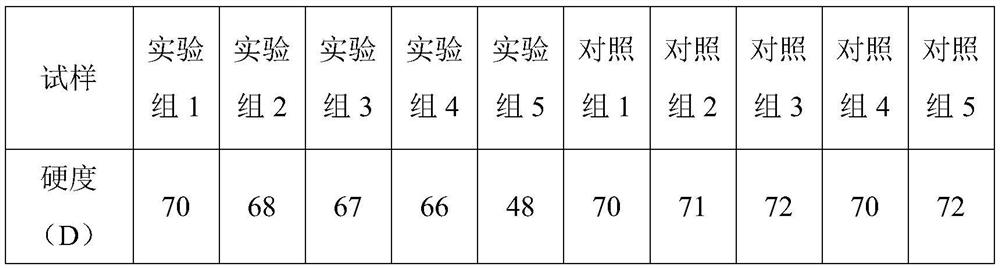

Examples

Embodiment 1

[0024] This embodiment relates to a composite insulator low temperature resistant hard sheath cycloaliphatic epoxy resin injection material, which includes, in parts by weight: 100 parts of epoxy resin, 100 parts of curing agent, 5 parts of toughening agent, accelerator 1 part, 1 part of flame retardant, 0.5 part of silane coupling agent, 2 parts of silicon dioxide, 150 parts of aluminum hydroxide filler; Wherein, described epoxy resin comprises 95% (being 95 parts by weight of epoxy resin) ) of the a material and 5% (i.e. 5 parts) of the b material of epoxy resin weight portion, a material is 3,4-epoxycyclohexyl carboxylate-3 ', 4'-epoxy cyclohexyl methyl ester, b material It is polyether polyol.

[0025] The above-mentioned curing agent is a combination of tetrahydrophthalic anhydride and methyl tetrahydrophthalic anhydride; the above-mentioned toughening agent is a combination of hydroxyl-terminated liquid rubber and epoxy-terminated liquid rubber. The aforementioned silic...

Embodiment 2

[0032] This embodiment involves a composite insulator low temperature resistant hard sheath alicyclic epoxy resin injection material, which includes, in parts by weight: 100 parts of epoxy resin, 60 parts of curing agent, 20 parts of toughening agent, accelerator 9 parts, 10 parts of flame retardants, 5 parts of silane coupling agents, 10 parts of silicon dioxide, 100 parts of aluminum hydroxide fillers; Wherein, described epoxy resin comprises 70% (being 70 parts by weight of epoxy resin) ) material a and 30% (i.e. 30 parts) of material b by weight of epoxy resin, material a is bis ((3,4-epoxycyclohexyl) methyl) adipate, and material b is polyethylene Diol diglycidyl ether.

[0033] The above-mentioned curing agent is hexahydrophthalic anhydride; the above-mentioned toughening agent is carboxyl-terminated liquid rubber. The aforementioned silica is a combination of nano silica and micro silica.

[0034] The preparation method of the cycloaliphatic epoxy resin injection mate...

Embodiment 3

[0036] This embodiment relates to a composite insulator low temperature resistant hard sheath cycloaliphatic epoxy resin injection material, which includes, in parts by weight: 120 parts of epoxy resin, 100 parts of curing agent, 50 parts of toughening agent, accelerator 1 part, 20 parts of flame retardant, 10 parts of silane coupling agent, 1 part of silicon dioxide, 250 parts of aluminum hydroxide filler; Wherein, described epoxy resin comprises 50% (being 60 parts by weight of epoxy resin) ) of material a and 50% (i.e. 60 parts) of material b by weight of epoxy resin, material a is 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl formate and caprolactone The combination of the polymerization product of cyclohexane-1,2-dicarboxylic acid diglycidyl ester, and the material b is polypropylene glycol diglycidyl ether.

[0037] The above-mentioned curing agent is a combination of methyl hexahydrophthalic anhydride and succinic anhydride; the above-mentioned toughening agent is core-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com