Water-based paint coating with air purification function and preparation method of water-based paint coating

An air purification and water-based paint technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsustainable purification performance, unsustainable purification performance, slow decomposition speed, etc., and achieves enhanced conductivity, low resistance, and degradation. Efficiency and depth of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

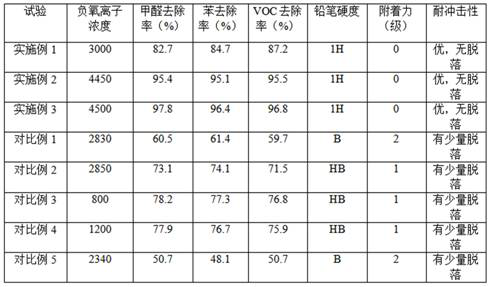

Examples

Embodiment 1

[0027] S1: Put the ultrasonically treated graphene oxide dispersion into the reaction kettle, raise the temperature to 150°C at a temperature of 5°C / min, and microwave for 3 hours at a power of 2000w to obtain three-dimensional network structure graphene;

[0028] S2: Add 8 parts of three-dimensional network graphene obtained in step S1, 1 part of nano-silicon dioxide, 1 part of nano-titanium dioxide, 0.3 parts of nano-manganese dioxide, and 10 parts of absolute ethanol into the reaction kettle. Stir and react at 500r / min for 2h to obtain the first air purification functional component;

[0029] S3: Add 5 parts of shell powder, 0.8 parts of tourmaline, 0.2 parts of sepiolite, and 30 parts of absolute ethanol into the reaction kettle, stir and react for 1 hour at a temperature of 120°C at a rate of 800r / min to obtain the second air purification functional group Minute;

[0030] S4: Add 10 parts of the first functional purification component obtained in step S2, 8 parts of the ...

Embodiment 2

[0033] S1: Add the ultrasonically treated graphene oxide dispersion into the reaction kettle, raise the temperature to 250°C at a temperature of 10°C / min, and react with microwaves at a power of 3000w for 6h to obtain graphene with a three-dimensional network structure;

[0034] S2: Add 10 parts of three-dimensional network graphene obtained in step S1, 3 parts of nano-silicon dioxide, 3 parts of nano-titanium dioxide, 0.5 parts of nano-manganese dioxide, and 20 parts of absolute ethanol into the reaction kettle. 800r / min stirred and reacted for 4h to obtain the first air purification functional component;

[0035] S3: Add 8 parts of shell powder, 1.5 parts of tourmaline, 0.5 parts of sepiolite, and 50 parts of absolute ethanol into the reaction kettle, and stir and react for 3 hours at a temperature of 150°C at a rate of 1000r / min to obtain the second air purification functional group Minute;

[0036] S4: Add 20 parts of the first functional purification component obtained i...

Embodiment 3

[0039] S1: Add the ultrasonically treated graphene oxide dispersion into the reaction kettle, raise the temperature to 240°C at a temperature of 8°C / min, and react with microwaves for 4.5h at a power of 2500w to obtain graphene with a three-dimensional network structure;

[0040] S2: Add 9 parts of three-dimensional network graphene obtained in step S1, 2 parts of nano-silicon dioxide, 2 parts of nano-titanium dioxide, 0.4 parts of nano-manganese dioxide, and 17 parts of absolute ethanol into the reactor, at a temperature of 110 ° C, at a rate of Stir and react at 700r / min for 3.5h to obtain the first air purification functional component;

[0041]S3: Add 7 parts of shell powder, 1.2 parts of tourmaline, 0.4 parts of sepiolite, and 45 parts of absolute ethanol into the reaction kettle, and stir and react at a temperature of 135°C at a speed of 950r / min for 2.5 hours to obtain the second air purification function components;

[0042] S4: Add 15 parts of the first functional pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com