Preparation method of energetic film ni-cr bridge wire pyrotechnic product with strong ignition ability

A kind of pyrotechnics, ni-cr technology, applied in the direction of offensive equipment, fuze, electrophoretic plating, etc., can solve the problems of in-situ synthesis operation trouble, small size of Ni-Cr bridge wire, etc., achieve convenient assembly and integration, improve resistance Electrostatic capacity, the effect of reducing the accumulation of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific steps for the preparation of energetic film Ni-Cr bridge wire pyrotechnics are as follows:

[0031] Step 1: Use deionized water as a solvent, configure a 0.1M copper sulfate solution, add sodium chloride and sodium citrate dihydrate with a concentration of 5mM, carbon paper as the cathode electrode, and use two-step electrophoretic deposition on carbon fiber paper. The upper clad copper layer, the electrophoresis parameter is the first 3mA / cm 2 25min deposition time, 30mA / cm after 2 deposition for 5min;

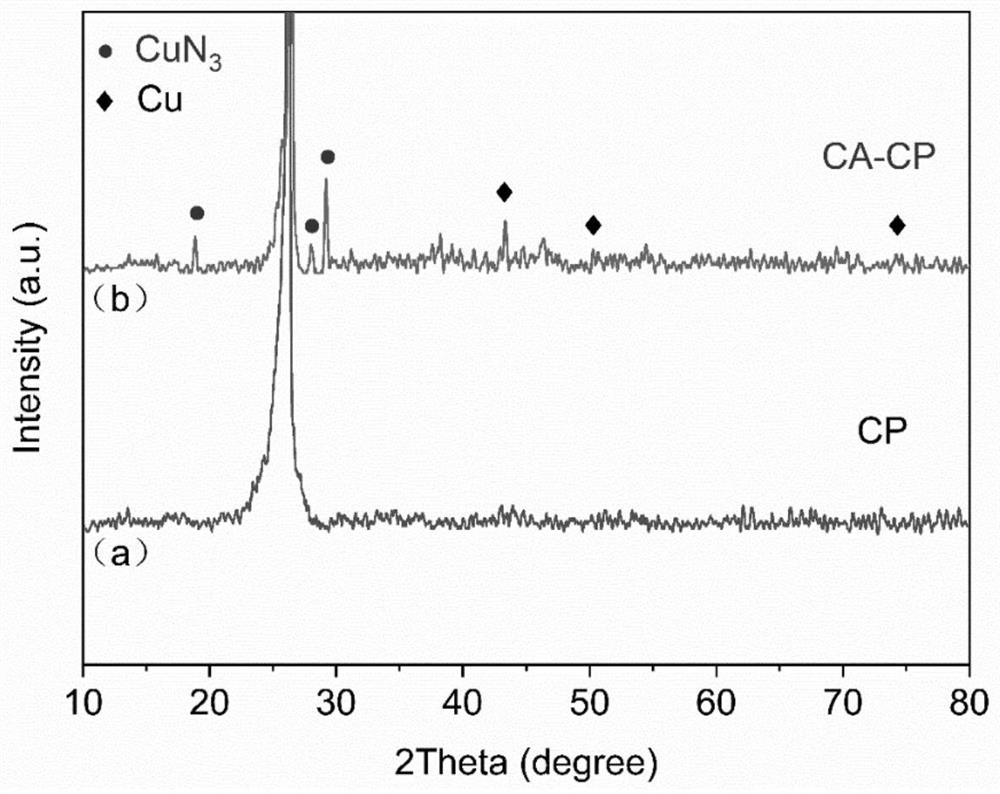

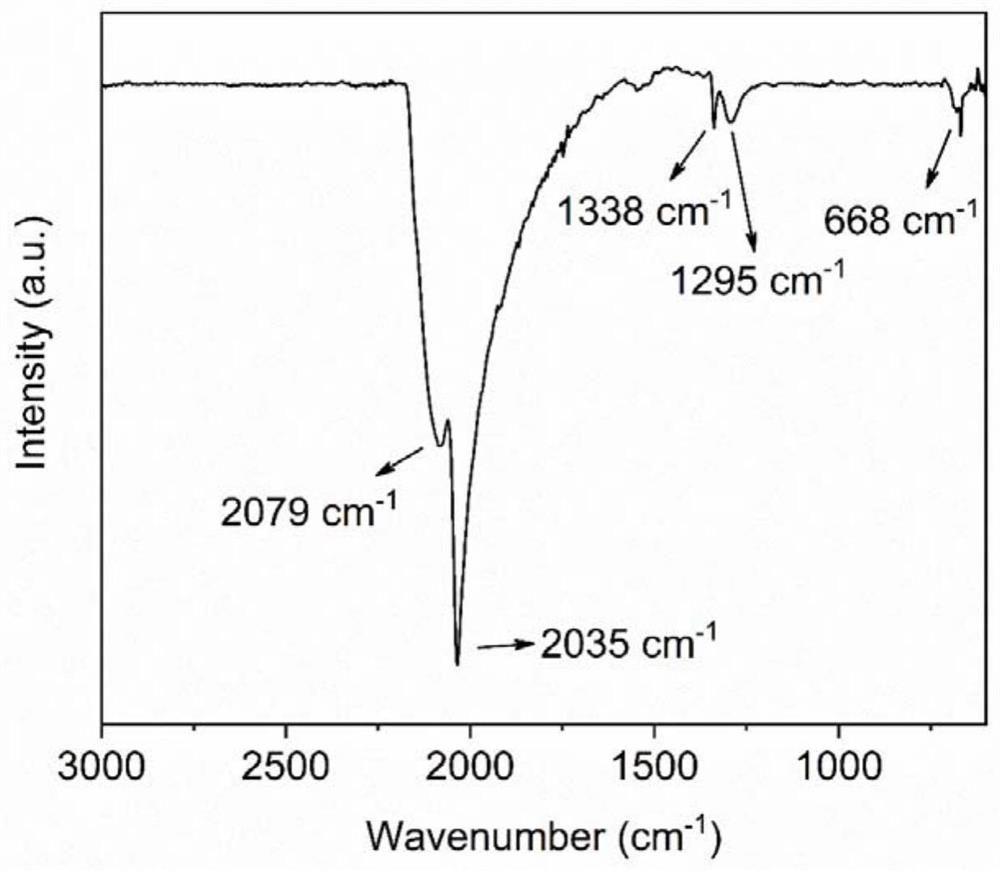

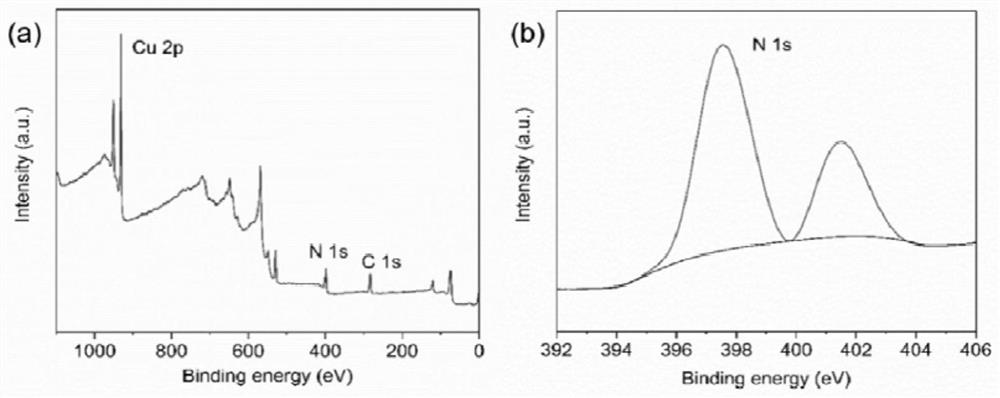

[0032] In the second step, the Cu-C obtained in the first step is used as the anode, and the 0.02M sodium azide aqueous solution is used as the electrolyte, and the current density is 2 mA / cm. 2 The azide reaction was carried out for 30min, washed and dried to obtain a cuprous azide film;

[0033] Step 3, assemble and integrate the cut cuprous azide film and the Ni-Cr bridge wire initiating product, and fix it with a Ni-Cr bridge wire pressing cap.

Embodiment 2

[0035] The specific steps for the preparation of energetic film Ni-Cr bridge wire pyrotechnics are as follows:

[0036] Step 1: Use deionized water as a solvent, configure 0.2M copper sulfate solution, add sodium chloride and sodium citrate dihydrate with a concentration of 5mM, carbon paper as the cathode electrode, and use two-step electrophoretic deposition on carbon fiber paper. The top is covered with copper layer, and the electrophoresis parameter is first 1mA / cm 2 30min deposition time, 20mA / cm after 2 deposition for 10min;

[0037] In the second step, the Cu-C obtained in the first step is used as the anode, and the 0.01M sodium azide aqueous solution is used as the electrolyte, and the current density is 5 mA / cm. 2 The azide reaction was carried out for 10 min, washed and dried to obtain a cuprous azide film;

[0038] Step 3, assemble and integrate the cut cuprous azide film and the Ni-Cr bridge wire initiating product, and fix it with a Ni-Cr bridge wire pressing ...

Embodiment 3

[0040] The specific steps for the preparation of energetic film Ni-Cr bridge wire pyrotechnics are as follows:

[0041] Step 1: Use deionized water as a solvent, configure 0.05M copper sulfate solution, add sodium chloride and sodium citrate dihydrate with a concentration of 1mM, carbon paper as the cathode electrode, and use two-step electrophoretic deposition on carbon fiber paper. The top is covered with copper layer, and the electrophoresis parameter is the first 5mA / cm 2 15min deposition time, 40mA / cm after 2 deposition for 5min;

[0042] In the second step, the Cu-C obtained in the first step is used as the anode, and the 0.02M sodium azide aqueous solution is used as the electrolyte, and the current density is 3 mA / cm. 2 The azide reaction was carried out for 20min, washed and dried to obtain a cuprous azide film;

[0043] Step 3, assemble and integrate the cut cuprous azide film and the Ni-Cr bridge wire initiating product, and fix it with a Ni-Cr bridge wire pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com