Production process of polygonatum sibiricum tea polyphenol tablet candy

A technology of tea polyphenol tableting and production process, applied in the field of tableting candy, can solve the problems of poor overall efficacy and difficult promotion, and achieve the effects of adjusting blood lipids, accelerating blood circulation, and reducing blood lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

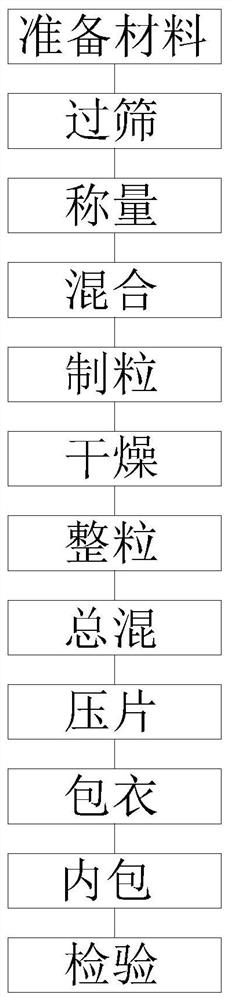

[0041] see figure 1 , the present invention provides the following technical solutions: a production process of Polygonatum polyphenols tablet candy, comprising the following steps:

[0042] S1: Prepare materials

[0043] Prepare buckwheat extract powder, green tea extract powder, kudzu root extract powder, sealwort extract powder, gardenia extract powder, lactose powder, corn starch, microcrystalline cellulose powder, silica powder, tea polyphenol powder, hard Magnesium fatty acid powder, coating powder, 85% ethanol, 70% ethanol;

[0044] S2: Sieve

[0045] Buckwheat extract powder, green tea extract powder, kudzu root extract powder, sealwort extract powder, gardenia extract powder, lactose powder, cornstarch, microcrystalline cellulose powder, silicon dioxide powder and tea polyphenol powder 80 mesh sieve to prepare buckwheat extract fine powder, green tea extract fine powder, kudzu root extract fine powder, sealwort extract fine powder, gardenia extract fine powder, lac...

Embodiment 2

[0072] see figure 1 , the present invention provides the following technical solutions: a production process of Polygonatum polyphenols tablet candy, comprising the following steps:

[0073] S1: Prepare materials

[0074] Prepare buckwheat extract powder, green tea extract powder, kudzu root extract powder, sealwort extract powder, gardenia extract powder, lactose powder, corn starch, microcrystalline cellulose powder, silica powder, tea polyphenol powder, hard Magnesium fatty acid powder, coating powder, 85% ethanol, 70% ethanol;

[0075] S2: Sieve

[0076] Buckwheat extract powder, green tea extract powder, kudzu root extract powder, sealwort extract powder, gardenia extract powder, lactose powder, cornstarch, microcrystalline cellulose powder, silicon dioxide powder and tea polyphenol powder 80 mesh sieve to prepare buckwheat extract fine powder, green tea extract fine powder, kudzu root extract fine powder, sealwort extract fine powder, gardenia extract fine powder, lac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com