Preparation method of ZnO-coated ZIF-8 core-shell nano composite material with efficient photocatalytic performance

A nanocomposite material and photocatalytic technology, which is applied in the field of preparation of ZnO@ZIF-8 core-shell nanocomposite materials, can solve the problems of large thickness and inability to significantly improve the photocatalytic efficiency of composite materials, and achieve the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

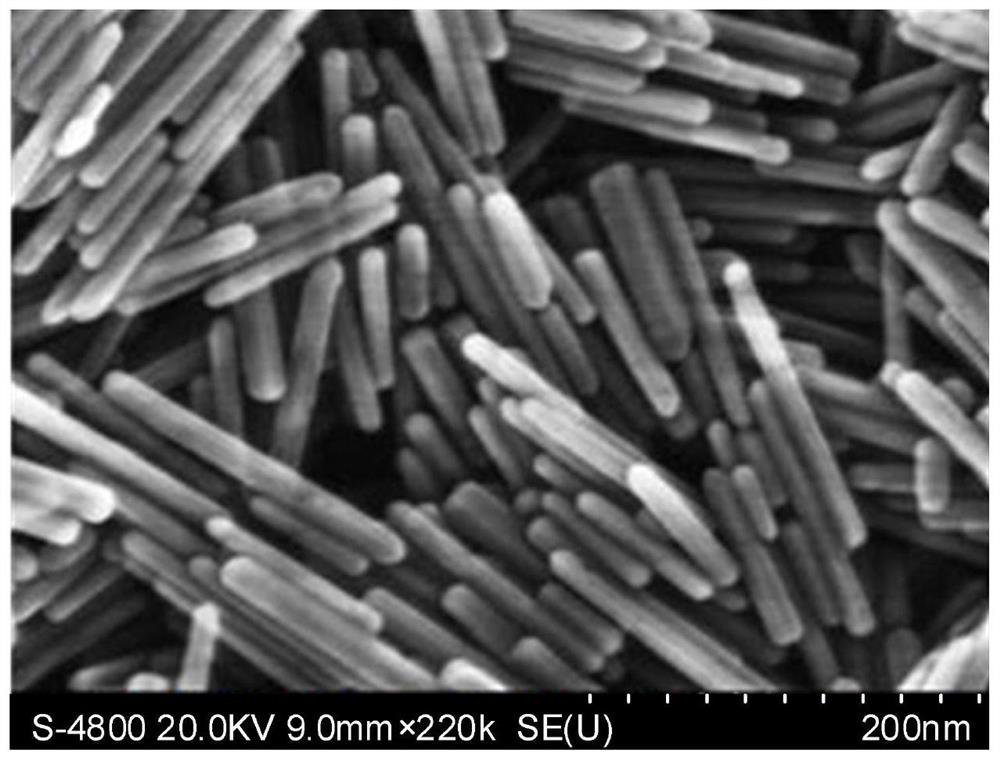

[0053] Add 14.8g of zinc acetate and 60ml of methanol solution into a 250ml round bottom flask, stir and dissolve; add 7.4g of potassium hydroxide and 32ml of methanol solution into a 100ml beaker, wait until completely dissolved and cool; add the potassium hydroxide solution to the zinc acetate The solution was stirred and reacted at 70° C. for 3 days; the reaction product was repeatedly washed with methanol and deionized water, and finally freeze-dried to obtain a white ZnO nanorod powder for future use.

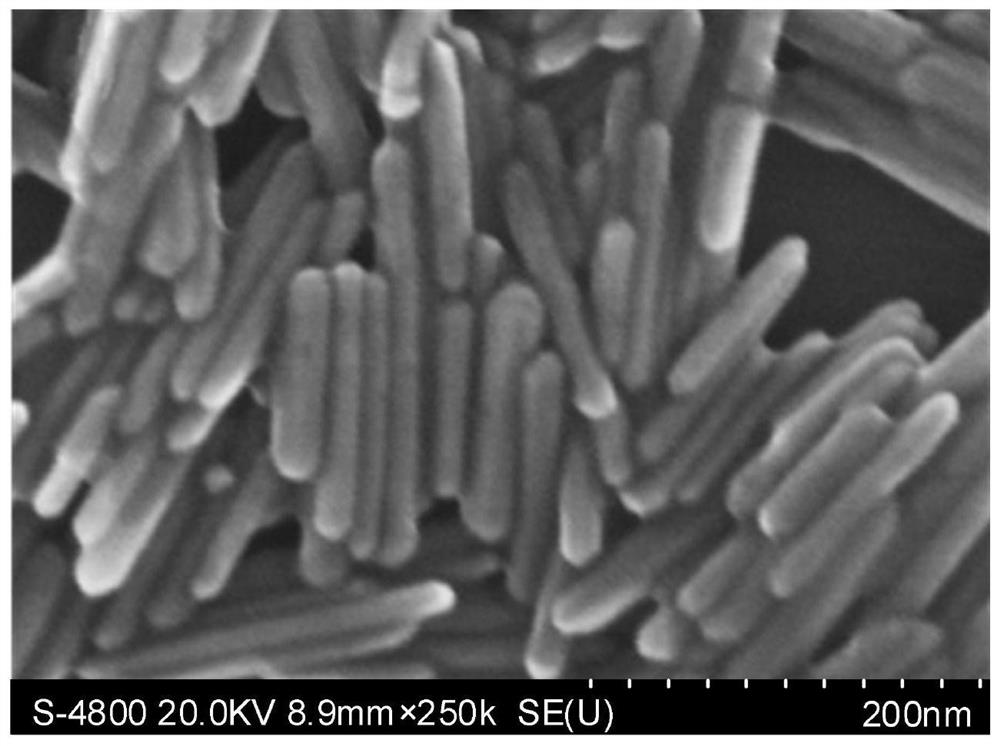

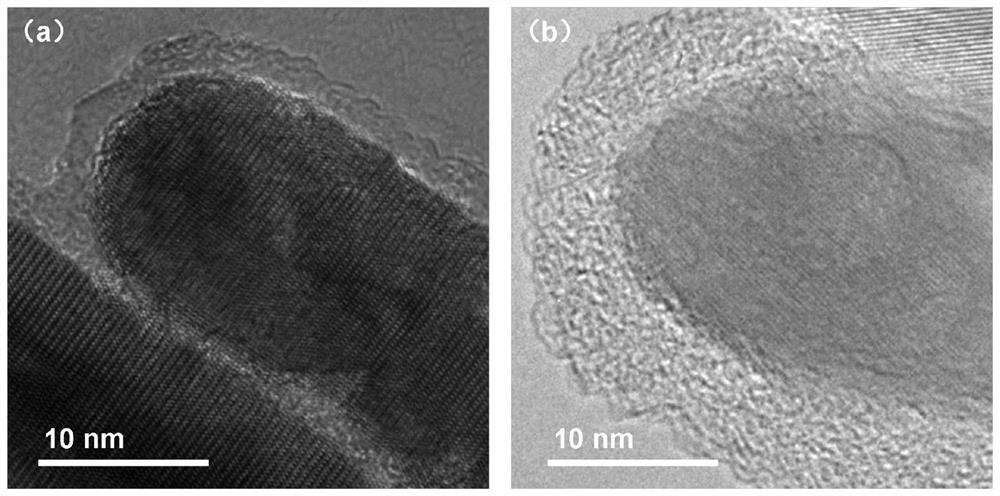

[0054] Weigh 0.3g ZnO nanorods (attached figure 1 ), 20mL of 2.0mg / ml methanol solution of 2-methylimidazole were added to a 50mL tetrapolyfluoride reaction kettle, and then 0.1ml of deionized water was added, and the closed reaction was carried out at 80°C for 24 hours. After washing and washing with water, the ZnO@ZIF-8 nanocomposite with core-shell structure was obtained by freeze-drying at -30 °C and drying time of 12 h (attached figure 2 , 3 a), the shell thickness...

Embodiment 2

[0061] Weigh 0.3g of ZnO nanorods and 20mL of 0.5mg / ml 2-methylimidazole ethanol solution into a 50mL PTFE reaction kettle, then add 0.1ml of deionized water, and react in a sealed environment at 75°C for 48 hours , the reaction product was repeatedly washed with alcohol and water, and then freeze-dried at -25°C for 13 hours to obtain a ZnO@ZIF-8 nanocomposite with a core-shell structure.

[0062] The preparation of the white powder of ZnO nanorods is the same as in Embodiment 1, and the following examples are all ZnO nanorods.

Embodiment 3

[0064] Weigh 0.3g of ZnO nanorods and 20mL of 2.0mg / ml methanol solution of 2-methylimidazole into a 50mL PTFE reaction kettle, then add 0.01ml of deionized water, and react in a sealed environment at 120°C for 72 hours , the reaction product was repeatedly washed with alcohol and water, and then freeze-dried at -20°C for 16 hours to obtain a ZnO@ZIF-8 nanocomposite with a core-shell structure. The shell of the zeolite imidazolate framework material The layer thickness is 5nm (attached image 3 b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com