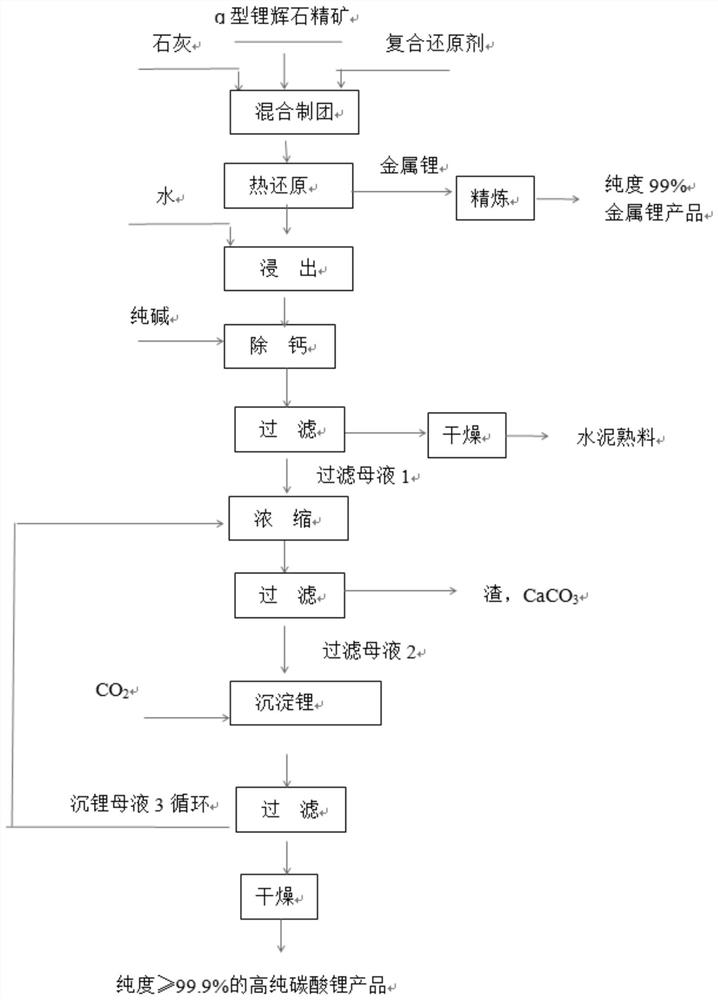

Method for preparing lithium carbonate through thermal reduction of spodumene

A spodumene, lithium carbonate technology, applied in lithium carbonate;/acid carbonate, cement production and other directions, can solve the problems of high recovery and processing cost, low value of sodium sulfate, poor market competitiveness, etc. High utilization value, simple process and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

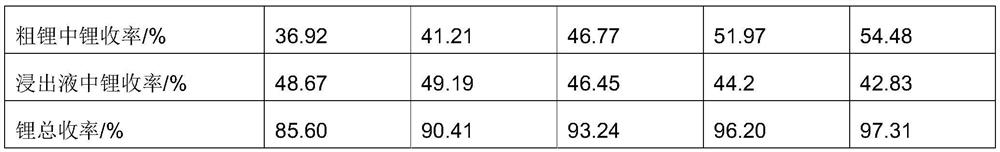

Embodiment 1

[0054] Take the α-type spodumene concentrate (which contains Li 2 O=6%) 1.0kg, with lime (its CaO content is 90%, particle size is 60-100um), composite reducing agent (composed of high-silicon ferrosilicon, aluminum powder, aluminum-silicon powder in a mass ratio of 1:0.1 -0.5:0.1-0.5 composition mixing) according to the mass ratio = 1:0.12:1.0, the total amount of solids added is 2.12kg, after the solids are mixed evenly, press to make dough, the size is 2.0cm in diameter and 1.0cm in thickness The cylindrical flakes are loaded into a graphite crucible sprayed with a ceramic anti-corrosion layer, and then the graphite crucible is placed in a special electric heating reduction furnace. Vacuumize the reduction furnace, control its absolute pressure to 15.0 Pa, turn on electricity to heat, control the temperature in the furnace to 900°C, and heat reduction time to 10 hours, then stop heating, release pressure, and naturally cool to normal temperature and pressure. Open the furn...

Embodiment 2

[0056] Get particle size and be-200 order, grade is 6.0% spodumene concentrate (it contains 2 O=6%) 1.0kg, with lime (it contains 95% CaO content, particle size is 60-100um), composite reducing agent (composed of high silicon ferrosilicon, aluminum powder, aluminum silicon powder is 1:0.1- 0.5: 0.1-0.5 (made by mixing) = 1: 0.3: 1.0 (mass ratio), the total amount of solids added is 2.3kg, after the solids are mixed evenly, press to make dough, its size is 2.0cm in diameter and 1.0cm in thickness Cylindrical flakes are loaded into a graphite crucible sprayed with a ceramic anti-corrosion layer, and then the graphite crucible is placed in a special reduction furnace (electric heating). Vacuumize the reduction furnace, control its absolute pressure to 8.0 Pa, turn on electricity to heat, control the temperature in the furnace to 1000°C, and heat reduction time to 10 hours, then stop heating, release pressure, and naturally cool to normal temperature and pressure. Open the furnac...

Embodiment 3

[0058] Get particle size and be-200 order, grade is 6.0% spodumene concentrate (it contains 2 O=6%) 1.0kg, with lime (it contains 95% CaO content, particle size is 60-100um), composite reducing agent (composed of high silicon ferrosilicon, aluminum powder, aluminum silicon powder is 1:0.1- 0.5: 0.1-0.5 (made by mixing) = 1: 0.5: 1.0 (mass ratio), the total amount of solids added is 2.5kg, after the solids are mixed evenly, press to make dough, the size of which is 2.0cm in diameter and 1.0cm in thickness Cylindrical flakes are loaded into a graphite crucible sprayed with a ceramic anti-corrosion layer, and then the graphite crucible is placed in a special reduction furnace (electric heating). Vacuumize the reduction furnace, control its absolute pressure to 5.0 Pa, turn on electricity to heat, control the temperature in the furnace to 1100°C, and heat reduction time to 10 hours, then stop heating, release pressure, and naturally cool to normal temperature and pressure. Open t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com