Chlorosulfonated poly(propylene carbonate) and preparation method thereof

A technology of chlorosulfonated polypropylene carbonate and polypropylene carbonate, applied in polycarbonate coatings, coatings, adhesives and other directions, can solve the problems of less research on modification, difficult promotion and application, complicated modification methods, etc. To achieve the effect of reducing the molecular weight, the method is simple and easy, and the electronegativity is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

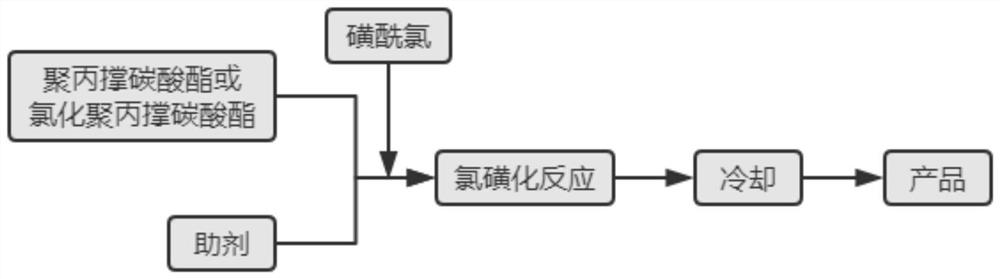

[0051] The invention provides a kind of preparation method of chlorosulfonated polypropylene carbonate, comprises the following steps:

[0052] 1) The poly(propylene carbonate) and / or the chlorinated poly(propylene carbonate) and the chlorosulfonation reagent are subjected to a chlorosulfonation reaction to obtain the chlorosulfonated poly(propylene carbonate).

[0053] The present invention is to the structure, parameter and degree of polymerization etc. of the chlorosulfonated polypropylene carbonate in the preparation method of described chlorosulfonated polypropylene carbonate, and corresponding preferred scheme, and the aforementioned chlorosulfonated polypropylene carbonate The structures, parameters, degree of aggregation, etc., and the corresponding preferred schemes can preferably correspond one by one, and details will not be repeated here.

[0054] In the present invention, polypropylene carbonate and / or chlorinated polypropylene carbonate, and chlorosulfonating rea...

Embodiment 1

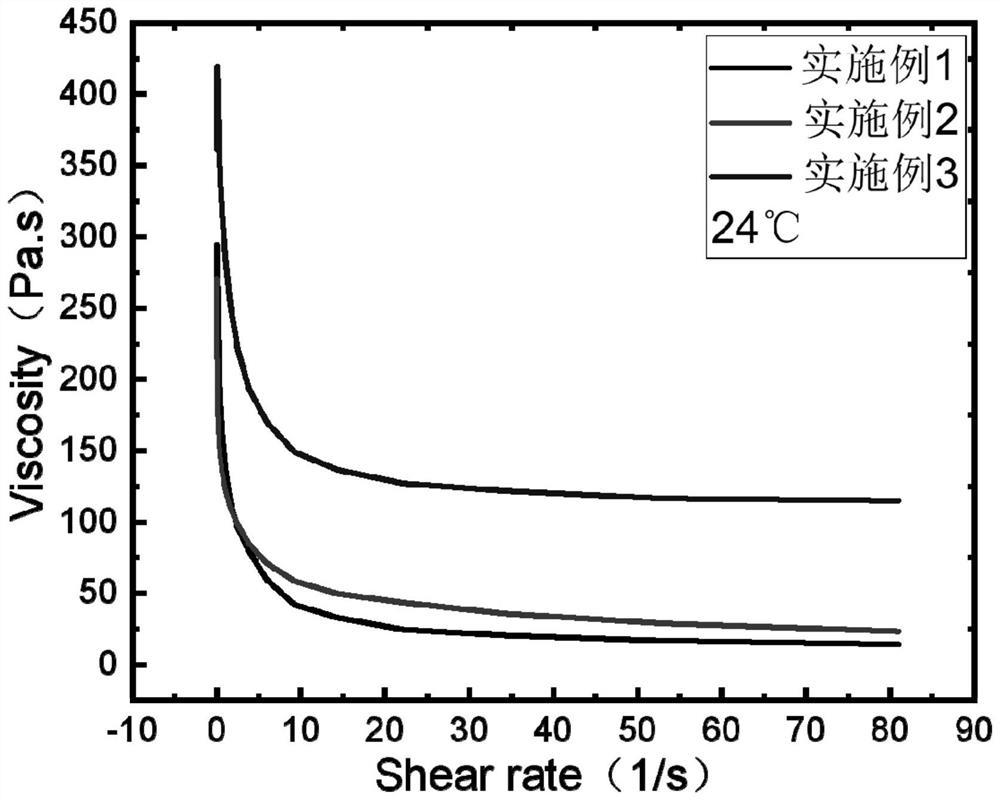

[0079] 20g polypropylene carbonate (PPC) and 3g silicon dioxide (SiO 2 ) into a three-necked flask, silicon dioxide is a dispersant, mechanically stirred; add 5.4g of sulfonyl chloride (SO 2 Cl 2 ), then heated up to 110°C in an oil bath, treated the tail gas with sodium hydroxide solution, carried out chlorosulfonation reaction for 60min, then immediately poured into a petri dish, cooled at room temperature, and obtained chlorosulfonated polypropylene carbonate in a translucent gel state ester.

[0080] The chlorosulfonated polypropylene carbonate prepared in Example 1 of the present invention was characterized and tested.

[0081] see figure 2 , figure 2 A photo of the appearance of the chlorosulfonated polypropylene carbonate prepared in Example 1 of the present invention.

[0082] The products obtained in the examples of the present invention were tested by normal temperature gel permeation chromatography.

[0083] Referring to Table 1, Table 1 shows the molecular ...

Embodiment 2

[0099] 20g polypropylene carbonate (PPC) and 3g silicon dioxide (SiO 2 ) into a three-necked flask, silicon dioxide is a dispersant, mechanically stirred; add 5.4g of sulfonyl chloride (SO 2 Cl 2 ), then heated up to 110°C in an oil bath, treated tail gas with sodium hydroxide solution, and carried out chlorosulfonation reaction for 70 minutes, then immediately poured into a petri dish, cooled at room temperature, and obtained transparent semi-fluid chlorosulfonated polypropylene carbonate.

[0100] The chlorosulfonated polypropylene carbonate prepared in Example 2 of the present invention was characterized and tested.

[0101] see Figure 5 , Figure 5 A photo of the appearance of the chlorosulfonated polypropylene carbonate prepared in Example 1 of the present invention.

[0102] The products obtained in the examples of the present invention were tested by normal temperature gel permeation chromatography.

[0103] Referring to Table 1, Table 1 shows the molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com