A Measuring System for Large Aperture Optical Components Based on Ultrafast Laser Imaging

A technology of optical components and measurement systems, which is applied in the direction of optical instrument testing, measuring devices, and testing optical properties, etc., can solve problems such as large-scale and high-speed measurement of optical components, and achieve the effects of widening applications, high flatness, and flexible evaluation modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

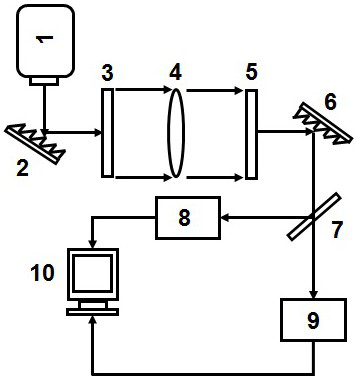

[0034] Such as figure 1 As shown in the figure, a transmission-type large-aperture optical element measurement system is shown in the figure.

[0035] The laser 1 generates ultrafast pulse laser under its normal operation, and the laser has the characteristics of wide spectrum, high coherence, high flatness, ultrafast pulse and so on.

[0036] The laser beam passes through the first diffraction grating 2 to undergo Fraunhofer diffraction, and the frequency domain (spectrum) information of the pulsed laser is mapped to the linear space domain in a one-to-one correspondence.

[0037] After passing through the first cylindrical prism or VIPAS, the line-like spot is converted into a rectangular spot through the method of cylindrical prism imaging or virtual imaging.

[0038] The light spot irradiates on the first optical element under test 4 , transmits through the first optical element under test 4 and carries its amplitude and phase information in real time.

[0039] The trans...

Embodiment 2

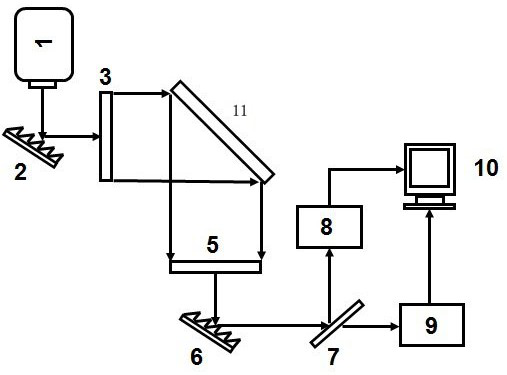

[0042] Such as figure 2 As shown in the figure, a reflective large-aperture optical element measurement system is shown in the figure.

[0043] The laser 1 generates ultrafast pulse laser under its normal operation, and the laser has the characteristics of wide spectrum, high coherence, high flatness, ultrafast pulse and so on.

[0044] The laser beam passes through the first diffraction grating 2 to undergo Fraunhofer diffraction, and the frequency domain (spectrum) information of the pulsed laser is mapped to the line-like space domain in a one-to-one correspondence.

[0045] After passing through the first light beam adjustment member 3, the line-like spot is converted into a rectangular spot by means of cylindrical prism imaging or virtual imaging.

[0046] The light spot is irradiated on the second optical element under test 11 , reflected on the second optical element under test 11 and carries its amplitude and phase information in real time.

[0047] The reflected li...

Embodiment 3

[0050] When conducting system verification experiments for specific optics. Attach the standard plate of standard size to the optical element to be tested. Through the final signal processing, it can be seen that the corresponding three occlusion lines have three obvious corresponding peaks in the signal, and the measured width is consistent with the actual width. The large-diameter optical element measurement system based on ultrafast laser imaging provided by the present invention can be applied to real-time monitoring of large-diameter optical elements in high-power laser devices and static measurement of quality evaluation of large-diameter optical elements.

[0051] The laser 1 in Embodiments 1, 2 and 3 of the present invention can be a laser with optical fiber output, or a laser with spatial light output, and its output laser features mainly broad spectrum, high coherence, and high spectral flatness. Through the diffraction grating and Infraunhofer far-field diffraction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com