Medical natural polymer microsphere containing radionuclides as well as preparation method and application of medical natural polymer microsphere

A technology of natural macromolecules and radionuclides is applied in the field of medical natural macromolecular microspheres containing radionuclides and their preparation, and achieves the effects of good biocompatibility, simple preparation method and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1. Preparation of medical natural polymer microspheres

[0047] S1, weigh 5g of chitosan and dissolve it in 100mL of deionized water, mix well under ultrasonic and heating conditions, adjust the pH to 3 with 0.1M HCl, then add 10wt% NaIO to the reaction device 4 , at 40°C for 3 hours. After the reaction, add 10 mL of 0.1M ethylene glycol solution to terminate the oxidation reaction for 1 hour. Put the reaction solution into a dialysis bag with a molecular weight cut-off of 8000-14000 and place it in deionized water for dialysis. 3 days, and finally freeze-drying obtains aldehydated chitosan;

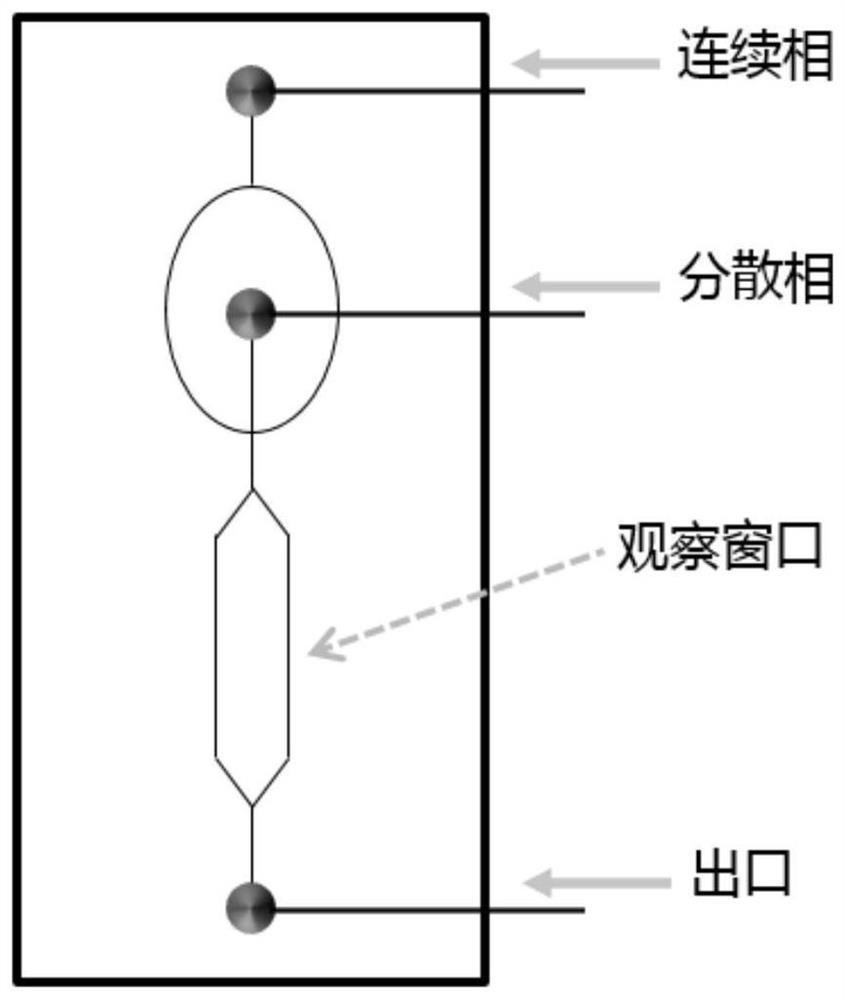

[0048] S2, weigh 1g of aldehylated chitosan, 0.5g of GelMA and 0.05g of lithium phenyl (2,4,6-trimethylbenzoyl) phosphate and mix it with phosphate buffer solution at 50°C, Filter with a 0.45 μm filter head to obtain the dispersed phase; then measure 40 mL of n-octane solution and 2 mL of Span-80 as the continuous phase, and use such as figure 1 The microfluidic devic...

Embodiment 2

[0053] S1, weigh 3g of sodium alginate and dissolve it in a three-necked brown flask filled with 60mL of deionized water, mix well under ultrasonic and heating conditions, adjust the pH to 3 with 0.1M HCl, and then add 20wt% NaIO to the reaction device 4 , at 40°C for 4 hours. After the reaction, add 6 mL of 0.1M ethylene glycol solution to terminate the oxidation reaction for 1.5 hours. Put the reaction solution into a dialysis bag with a molecular weight cut-off of 8000-14000 and place it in deionized water. Dialysis for 3 days, and finally freeze-drying to obtain alginate sodium alginate;

[0054] S2, weigh 1.5g of alginate sodium alginate, 0.8g of GelMA and mix with phosphate buffer solution evenly at 40°C, filter while hot with a 0.45μm filter head to obtain the dispersed phase; then measure 50mL of liquid paraffin and 3mL of Class-60 is used as the continuous phase, such as figure 1 The microfluidic device shown (the flow rate ratio of the dispersed phase and the contin...

Embodiment 3

[0059] S1, take 6g of starch and dissolve it in a three-necked brown flask with 100mL of deionized water, adjust the pH to 2 with 0.1M HCl, then add 10wt% NaIO to the reaction device 4 , oxidation reaction at 40°C for 4 hours, after the reaction, add 10mL 0.1M ethylene glycol solution to terminate the oxidation reaction for 2 hours, put the reaction solution into a dialysis bag with a molecular weight cut-off of 8000-14000, place it in deionized water for dialysis 3 days, and finally freeze-dried to obtain the formylated starch;

[0060] S2, weigh 2g of aldylated starch and 1g of GelMA and mix them evenly with phosphate buffer solution at 50°C, filter while hot with a 0.45μm filter head to obtain the dispersed phase; then measure 60mL of rapeseed oil and 4mL of Span-80 As the continuous phase, using such as figure 1 The microfluidic device shown (the flow rate ratio of the dispersed phase and the continuous phase is 1:20) prepares microsphere droplets to obtain microsphere dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com