Method and device for recovering argon discharged in monocrystalline silicon preparation

The technology of a recovery device and a recovery method is applied in the field of argon gas discharge in the process of purifying and recovering single crystal silicon, which can solve the problems of high energy consumption, low recovery rate of argon gas, and inability to overcome the problem of nitrogen accumulation, and achieve low energy consumption, The effect of reducing energy consumption and gas consumption and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

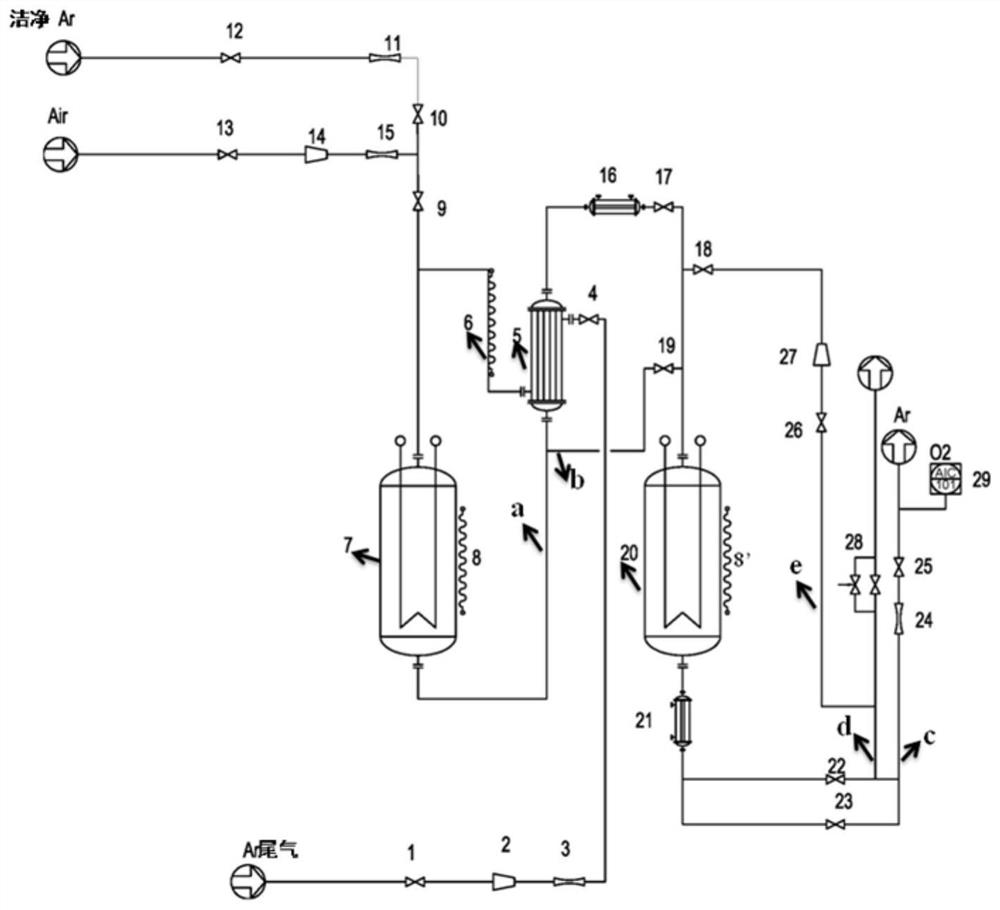

Method used

Image

Examples

Embodiment 1

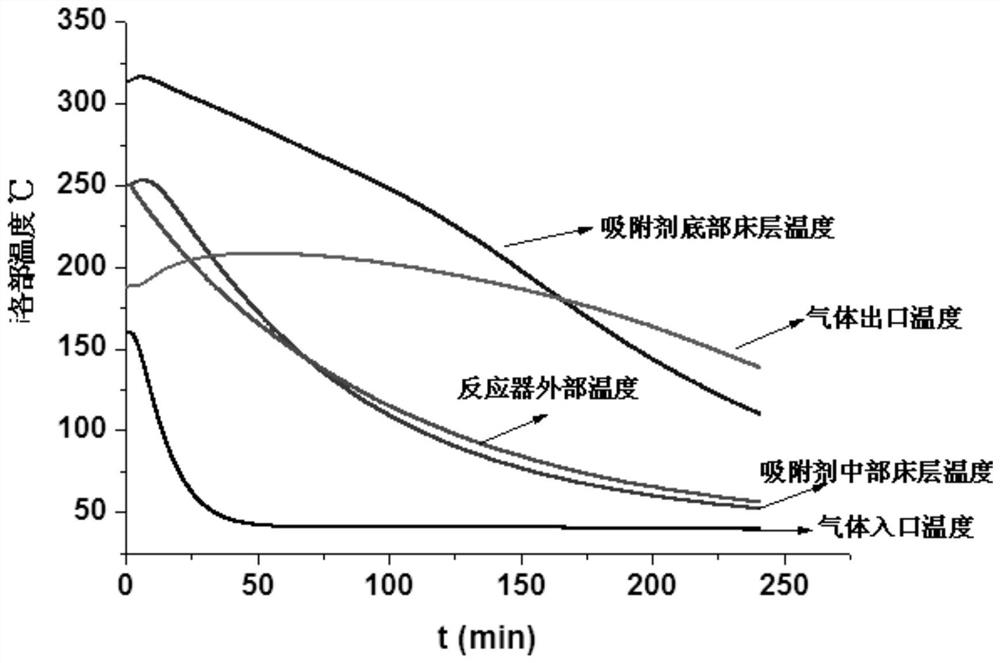

[0041] Embodiment 1, the pre-preparation process of the purification device: the temperature of the chemical looping combustion reactor (7) is raised to 270°C, the temperature of the adsorbent reactor (20) is raised to 250°C, the fifth valve (12) is opened, and the fourth valve (10) is , the third valve (9), the ninth valve (19), the eleventh valve (23), the twelfth valve (25), and all the other valves are closed. Adjust the argon gas flow meter from 11 to 10 L / min, keep it for 5 hours, and remove the impurities of oxygen carrier and adsorbent. Cooling process: open the tenth valve (22), the thirteenth valve (26), the eighth valve (18), and the rest of the valves are closed. Turn on the fan (27) and the second circulating water cooling device (21) to cool the adsorbent in the adsorbent reactor (20). For the specific cooling curve, refer to the attached figure 2 .

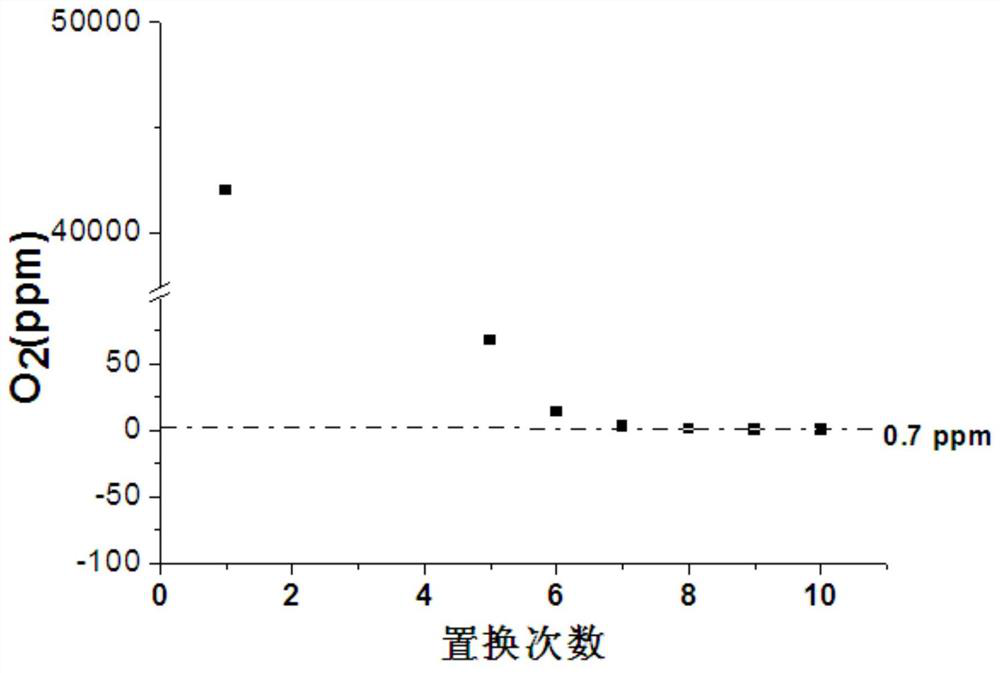

[0042] Replacement process, open the fifth valve (12), the fourth valve (10), the third valve (9), the second ...

Embodiment 2

[0044] Embodiment 2, regeneration process: open the fifth valve (12), the sixth valve (13), the fourth valve (10), the third valve (9), the ninth valve (19), the tenth valve (22), Fourteenth valve (28), all the other valves are closed. Adjust the second gas mass flow meter (11) to 50L / min. Adjust the third gas mass flow meter (15) to 10L / min, and open the air cooling dryer (14), the second circulating condensed water cooling device (21), and then the adsorbent reactor (20) is heated to 250 ° C, Keep for 2h. Then close the second gas mass flow meter (11), adjust the third gas mass flow meter (15) to 100L / min, keep it for another 2h, and end the regeneration process. The follow-up process repeats the cooling process and replacement process.

Embodiment 3

[0045] Example 3: The overall energy consumption monitoring of the reaction device after 152 hours of operation Refer to Table 1 for specific comparison results.

[0046] Table 1 Average energy consumption monitoring of purification equipment

[0047]

[0048] Explanation: The purification device has been running for 152 hours, and 10 switching operations have been carried out. It is detected that the average energy consumption during the operation of the device is about 4.5kW / h. Without purification device, about 547m of argon gas is needed 3 , and after using the purification device, only argon 47m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com