High-tap-density spherical graphite as well as preparation method and application thereof

A technology of spherical graphite and tap density, which is applied to graphite, chemical instruments and methods, structural parts, etc., can solve the problems of low tap density of spherical graphite, affecting the volume specific energy of natural graphite negative electrode tap density batteries, etc., to improve The effect of tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0040] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

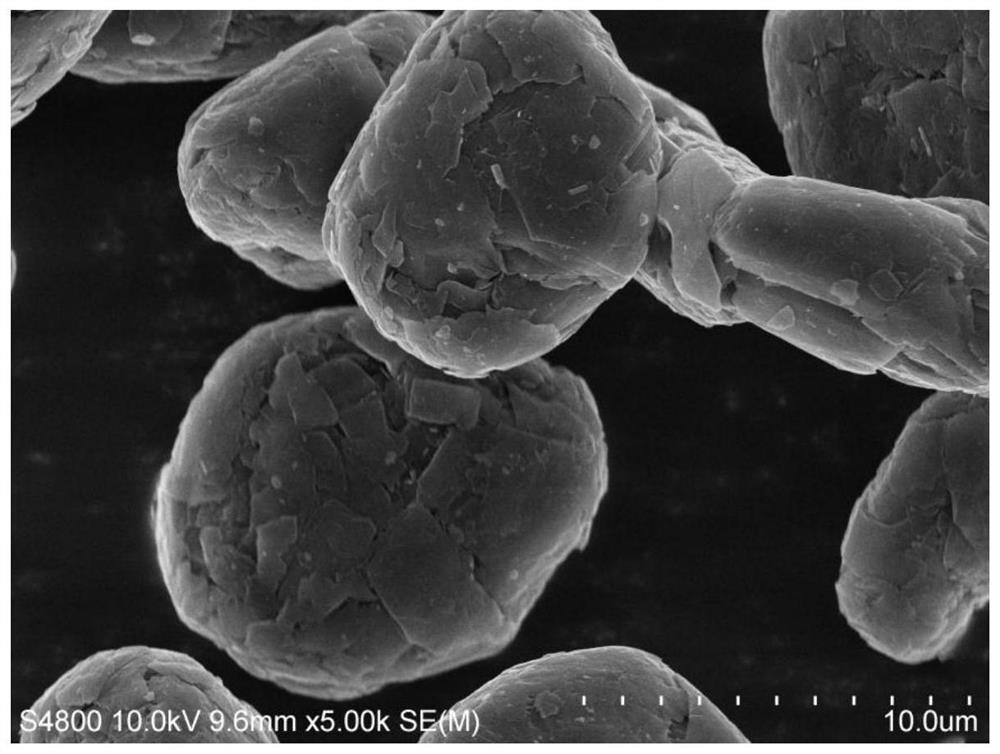

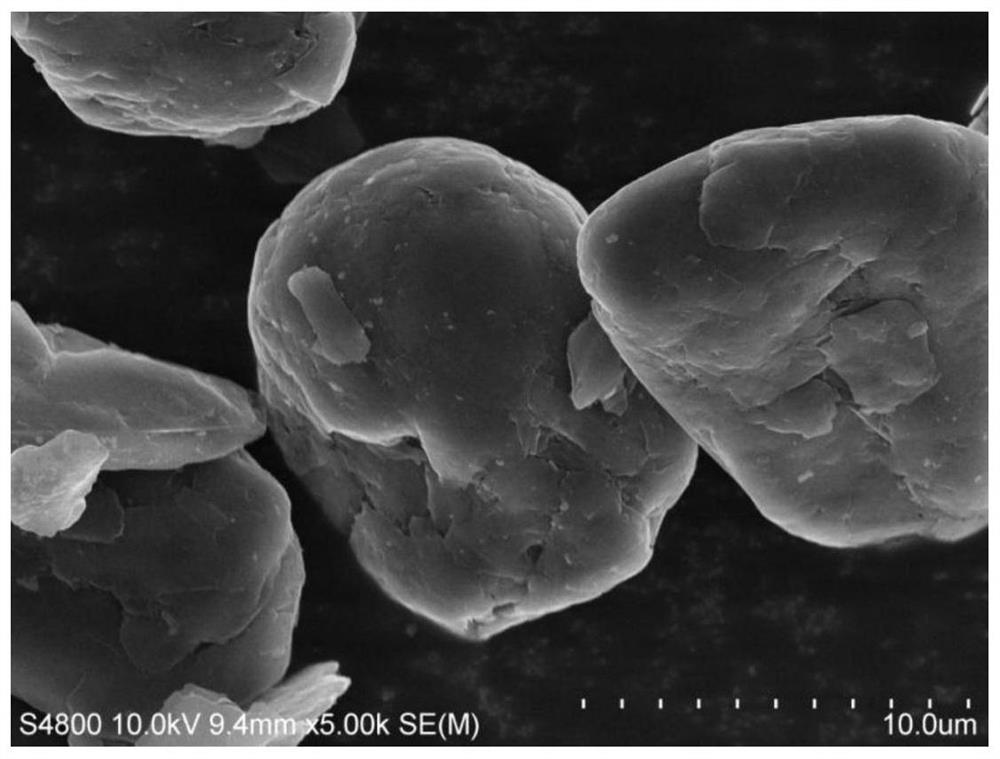

[0042] At room temperature, 10g of spherical graphite (D 50 8μm, tap density 0.7g / cm 3 , The specific surface area is 9.5m 2 / g) immersed in a saturated hydrogen peroxide solution and stirred for 50 minutes, washed with deionized water and then dried at 100° C. to obtain an intermediate product. The intermediate product was heated to 500° C. for 30 minutes under a nitrogen atmosphere, and then cooled to room temperature. Then it was processed in a fusion machine (rotating speed 1160r / min) for 15 minutes to obtain highly compacted spherical graphite. Then, the high softening point asphalt with a softening point of 200°C was crushed to 3 μm in an impact mill, and mixed with the high-tapping spherical graphite prepared above at a mass ratio of 0.8:100. 2 Under protection, treat at 1200°C for 4 hours, cool to room temperature, disperse, sieve, and demagnetize to obtain natural graphite negative electrode material.

Embodiment 2

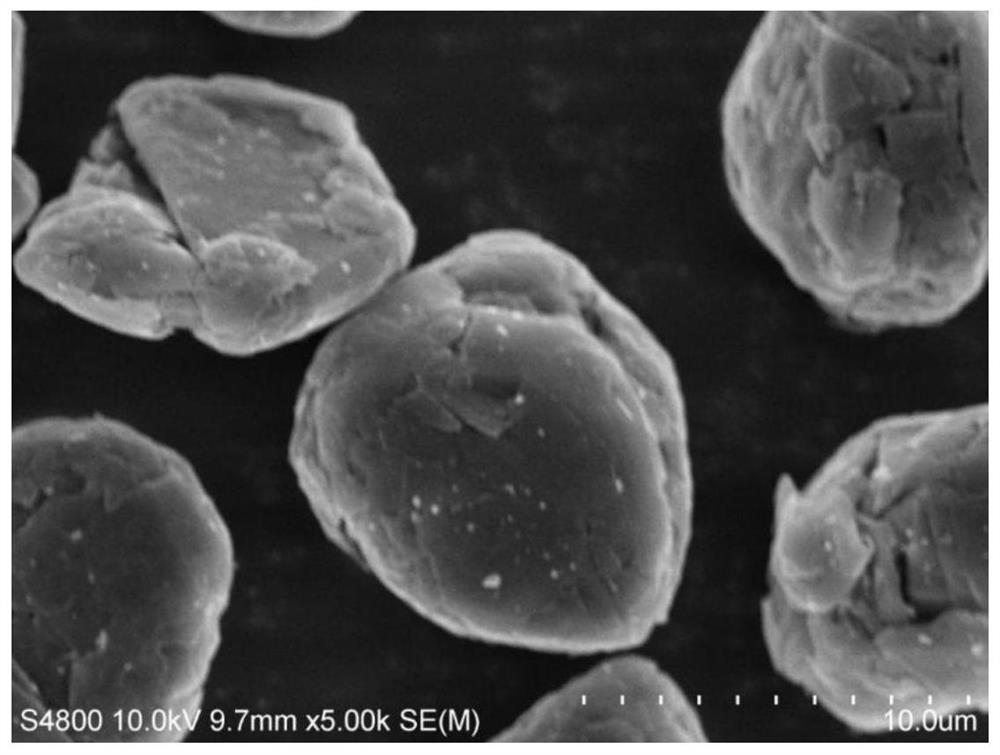

[0044] At room temperature, 10 g of spherical graphite (D 50 16μm, tap density 0.9g / cm 3 , The specific surface area is 6.5m 2 / g) immersed in a saturated solution of sodium hypochlorite and stirred for 30 minutes, washed with deionized water and then dried at 80° C. to obtain an intermediate product. The intermediate product was heated to 400° C. for 50 minutes under a nitrogen atmosphere, and then cooled to room temperature. Then it was processed in a fusion machine (rotating speed 1080r / min) for 10 minutes to obtain highly compacted spherical graphite. Put the high-tapped spherical graphite prepared above into a rotary furnace, and in an argon atmosphere with a flow rate of 100 L / min and an environment of 800 ° C, feed methane at a flow rate of 1 L / min for 2 hours, and then switch to argon. gas, cooled to room temperature, dispersed, sieved, and demagnetized to obtain the natural graphite anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com