Method for preparing high-purity accelerant CZ through purification, and application of high-purity accelerant CZ

A kind of accelerator, high-purity technology, applied in the field of purifying and preparing high-purity accelerator CZ, high-purity and chromatographic-grade purity accelerator CZ, can solve the problems of residue, the structure is not particularly stable, the solubility is general, etc., and the purification process is fast. , Conducive to drying, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

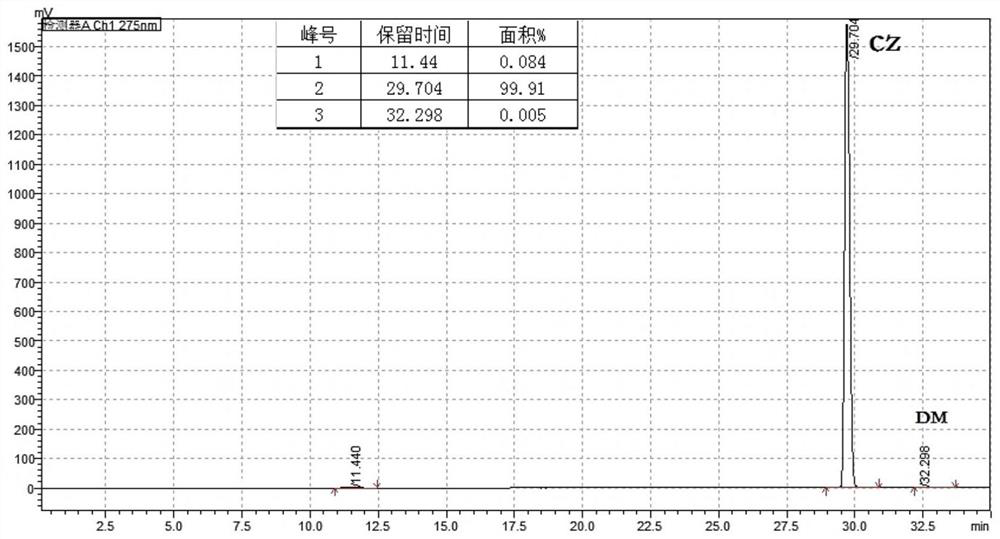

[0055] At normal temperature, add 150g slightly light yellow commercially available CZ (manufactured by Kemai, with a purity of 98.4%), 50g tetrahydrofuran, and 2g cyclohexylamine into a 500ml reaction flask equipped with a stirring device, a thermometer and a reflux condenser, and stir for 10min. Rapidly raise the temperature to 50°C, until all impurities visible to the naked eye are dissolved in tetrahydrofuran, and some CZ are not completely dissolved. Quickly cool down to 5°C in the ice-water mixture, add 70g of absolute ethanol, stir for 1min, transfer the mixture to a sand core funnel, filter with suction, and dry in vacuum at 35°C for 5h to obtain 115g of CZ in the form of white crystals. The product is chromatographed by HPLC Test, the area normalization method peak area is 99.49%.

[0056] Take 100g of CZ purified once, and purify once again according to the above-mentioned material addition ratio and operation steps to obtain 75g of purified CZ. The product is tested...

Embodiment 2

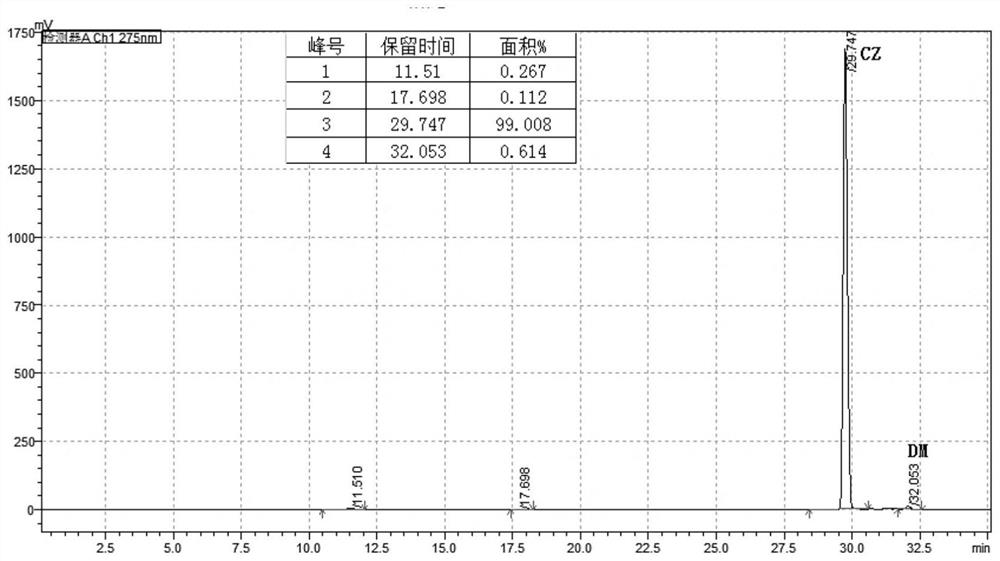

[0058] At normal temperature, 150g slightly light yellow commercially available CZ (manufactured by Kemai, with a purity of 98.4%), 35g tetrahydrofuran, and 0.8g cyclohexylamine were added to a 500ml reaction flask equipped with a stirring device, a thermometer and a reflux condenser, and stirred Rapidly raise the temperature to 55°C within 10 minutes until all impurities visible to the naked eye are dissolved in tetrahydrofuran, and part of CZ is not completely dissolved. Quickly cool down to 5°C in the ice-water mixture, add 80g of absolute ethanol, stir for 1min, transfer the mixture to a sand core funnel, filter it with suction, and dry it in vacuum at 35°C for 5h to obtain 120g of CZ in the form of white crystals. The product was analyzed by HPLC Chromatography test, the area normalization method peak area is 99.40%, almost does not contain DM peak in the product.

Embodiment 3

[0060] Step 1: Preparation of accelerator CZ (water phase method)

[0061] Add 83.5g (0.5mol) of accelerator M, 178g (1.8mol) of cyclohexylamine, 0.6g of copper sulfate, and 500g of distilled water into a 1000ml reaction flask equipped with a stirring device, a thermometer and a reflux condenser, and stir evenly; 68g (0.6mol) of 30% hydrogen peroxide, reaction temperature 40°C; hydrogen peroxide was added dropwise for 90 minutes, cooled to 20°C after the reaction, settled, filtered, and dried at 40°C for 12 hours to obtain 117g of dark yellow CZ crude product, which was chromatographed by HPLC According to the curve test, the purity is 92.7%.

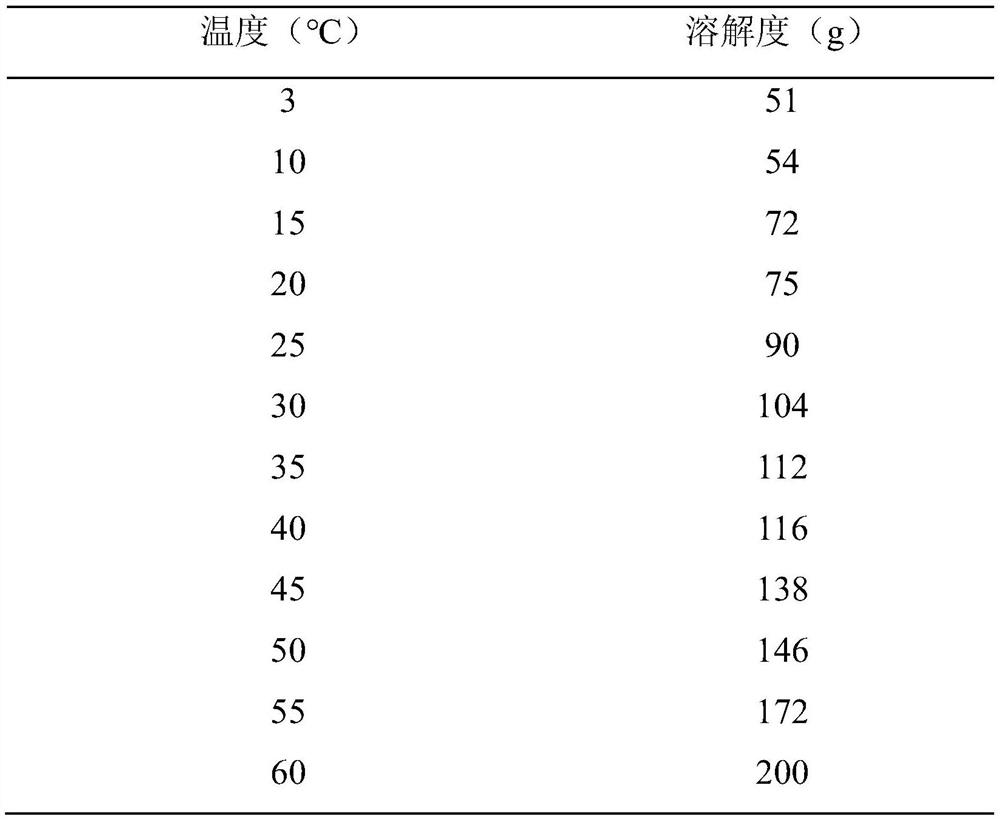

[0062] Step 2: Purification of Accelerator CZ

[0063] At room temperature, take 100g of CZ made in step 1, 50g of tetrahydrofuran, and 1.2g of cyclohexylamine into a 500ml reaction bottle equipped with a stirring device, a thermometer and a reflux condenser, and rapidly raise the temperature to 45°C within 10 minutes under stirring, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com