Preparation method of epoxy resins with low total chlorine content

A technology of total chlorine content and epoxy resin, which is applied in the field of preparation of epoxy resin with low total chlorine content, can solve problems such as epoxy resin anionic polymerization gel, purified epoxy resin viscosity, epoxy value change, etc., to meet the conditions Mildness, reduced by-product content, stable viscosity and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

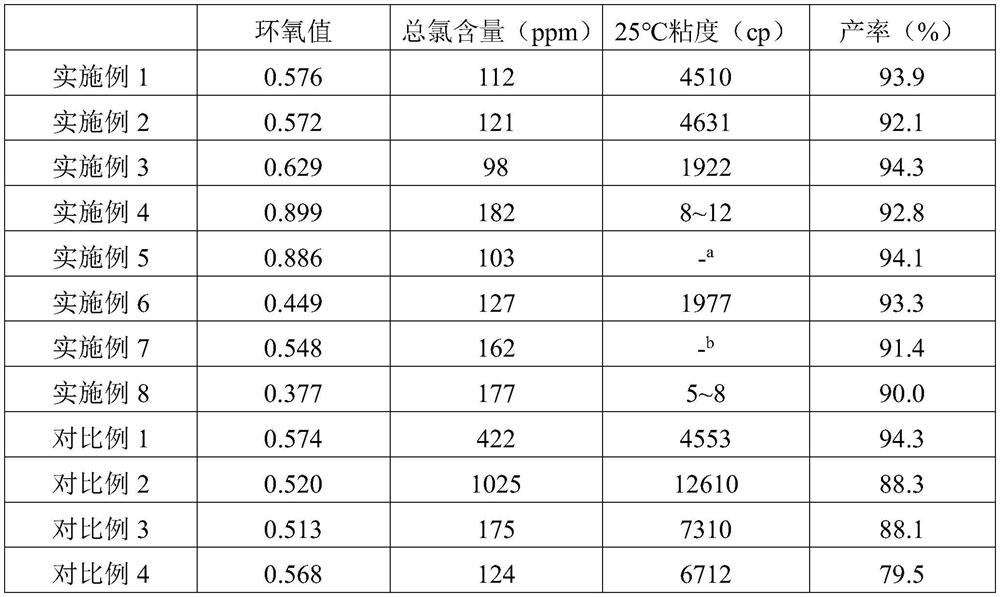

Examples

Embodiment 1

[0039] Embodiment 1, the synthesis of bisphenol A diglycidyl ether

[0040]Add 228g of bisphenol A, 555g of epichlorohydrin and 88g of dioxane into a 2000ml three-necked flask equipped with a mechanical stirrer, an azeotropic reflux dehydrator and a thermometer, stir and heat to 40°C. After the reaction solution was dissolved until transparent, 120 g of solid sodium hydroxide with an average particle diameter of 1.0 mm was added, and then the pressure was reduced (the vacuum degree in the reaction vessel was adjusted to 20 kPa), and the reaction was continued at 40° C. for 2.5 hours. After the reaction was completed, it was filtered while it was hot, and then subjected to vacuum distillation (distillation temperature 110° C., vacuum degree 0.5 kPa) to obtain 320.5 g of crude product.

[0041] The crude product was uniformly dissolved in 330 g of toluene, then 150 g of 10% sodium hydroxide aqueous solution was added, and the temperature was raised to 50° C. while stirring, and ...

Embodiment 2

[0043] Embodiment 2, the synthesis of bisphenol A diglycidyl ether

[0044] Add 228g of bisphenol A, 925.2g of epichlorohydrin and 156g of dimethyl sulfoxide into a 3000ml three-necked flask equipped with a mechanical stirrer, an azeotropic reflux dehydrator and a thermometer, stir and heat to 55°C. After the reaction solution was dissolved until transparent, 96 g of solid sodium hydroxide with an average particle diameter of 1.5 mm was added, and then the pressure was reduced (the vacuum degree in the reaction vessel was adjusted to 30 kPa), and the reaction was continued at 55° C. for 2 hours. After the reaction was completed, it was filtered while it was hot, and then subjected to vacuum distillation (distillation temperature 130° C., vacuum degree 0.5 kPa) to obtain 316 g of crude product.

[0045] The crude product was uniformly dissolved in 300 g of xylene, then 100 g of 5% sodium hydroxide aqueous solution was added, and the temperature was raised to 60° C. while stirri...

Embodiment 3

[0047] Embodiment 3, the synthesis of bisphenol F diglycidyl ether

[0048] Add 200g of bisphenol F, 740.2g of epichlorohydrin and 88g of dioxane into a 2000ml three-necked flask equipped with a mechanical stirrer, an azeotropic reflux dehydrator and a thermometer, stir and heat to 45°C. After the reaction solution was dissolved until transparent, 112 g of solid sodium hydroxide with an average particle diameter of 1.2 mm was added, and then the pressure was reduced (the vacuum degree in the reaction vessel was adjusted to 26 kPa), and the reaction was continued at 45° C. for 2.5 hours. After the reaction was completed, it was filtered while it was hot, and then subjected to vacuum distillation (distillation temperature 110° C., vacuum degree 0.5 kPa) to obtain 296.9 g of crude product.

[0049] The crude product was uniformly dissolved in 300 g of xylene, then 120 g of 10% sodium hydroxide aqueous solution was added, and the temperature was raised to 60° C. while stirring, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com