Lactobacillus fermentum for producing bacteriocin and application of lactobacillus fermentum in inhibiting production of albuginea in fermented food

A technology for fermenting Lactobacillus and producing bacteriocin, which is applied to the preservation of Lactobacillus, medical preparations containing active ingredients, and food ingredients as antimicrobial agents. It can solve the problems of complex operation steps, many equipment and instruments, and long time consumption. Achieve broad-spectrum antibacterial effect and strong antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

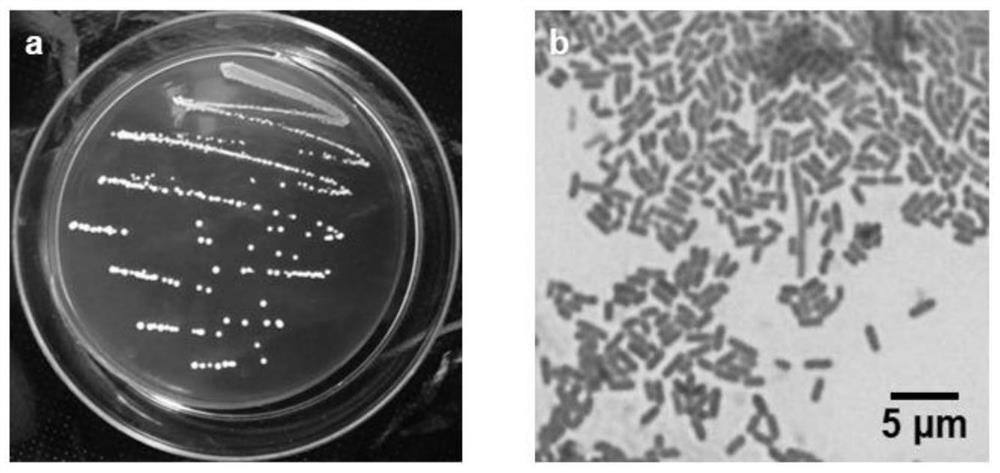

[0038] Embodiment 1, screening and identification of bacteriocin-producing lactic acid bacteria

[0039] 1 Experimental materials

[0040] 8 servings of traditional kimchi water collected from the homes of citizens in urban Chongqing.

[0041] 2 Experimental methods

[0042] 2.1 Isolation and purification of lactic acid bacteria

[0043] Take 1mL pickle water and use 10-fold dilution method for gradient dilution, and then dilute to 10 -4 . Take 100 μL of each dilution and spread it on the MRS solid medium, place it in a biochemical incubator at 37°C and incubate it for 48 hours, pick a single colony with different morphological characteristics to separate the strains by streaking on the plate, and streak repeatedly until a single colony is obtained , record the colony morphology and carry out Gram staining microscopic examination, and freeze-dry the purified strains for preservation.

[0044] 2.2 Activation and growth curve of indicator bacteria

[0045] Open the ampoule...

Embodiment 2

[0061] Embodiment 2, separation and purification identification and bacteriostatic activity of bacteriocin

[0062] 1 Experimental materials

[0063] The experimental strain was Lactobacillus fermentum SHY10.

[0064] 2 Experimental methods

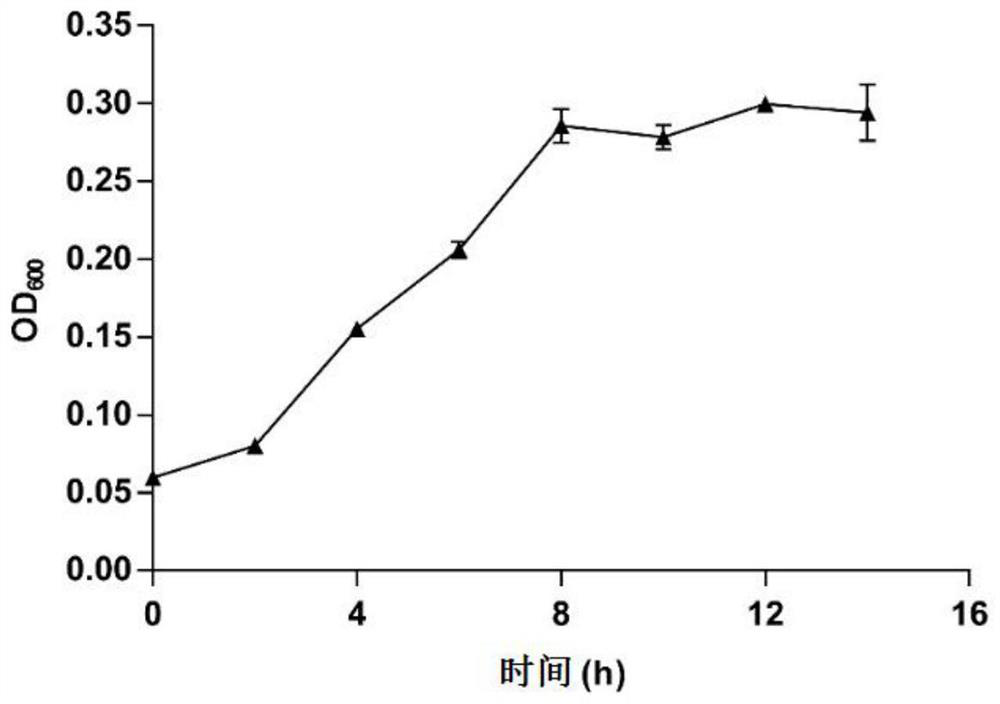

[0065] 2.1 Growth curve of Lactobacillus fermentum SHY10 and its antibacterial substances

[0066] After activating the freeze-dried Lactobacillus fermentum SHY10 obtained in Example 1, take 1% (v / v) cultured to the logarithmic phase and inoculate it in 100mL MRS broth, cultivate it at 37°C for 48h, and take samples every 2h , respectively test its OD 600nm , pH and antibacterial activity of the supernatant. Centrifuge at 4000rpm, 4°C for 10min to take the supernatant. The antibacterial activity of the supernatant was determined by the agar diffusion method.

[0067] 2.2 Crude extraction of bacteriocins

[0068] (1) Activate Lactobacillus fermentum SHY10. After activation, take 1% (v / v) cultured to the logarithmic phase of the bact...

Embodiment 3

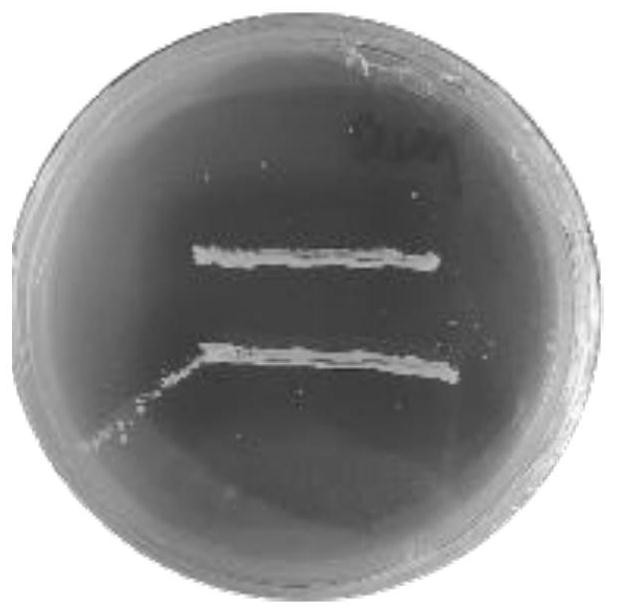

[0108] Example 3, the application of Lactobacillus fermentum SHY10 in inhibiting the growth of white film in fermented food

[0109] 1 Experimental materials

[0110] The experimental strain was Lactobacillus fermentum SHY10.

[0111] Candida parapsilosis, isolated from pickle water producing albuginea.

[0112] 2 Experimental methods

[0113] 2.1 Determination of the amount of white film formation by Lactobacillus fermentum SHY10

[0114] Candida parapsilosis was cultured in YPD liquid medium at 25°C for 18 hours, Lactobacillus fermentum SHY10 was cultured in MRS broth at 37°C for 12 hours, and set aside. Take 1 mL of the above-mentioned Candida parapsilosis liquid and culture it in a 48-well cell plate (control group); take 0.5 mL of Lactobacillus fermentum SHY10 and 0.5 mL of the Candida parapsilosis liquid in the cell plate (experimental group). Cultivate at 37°C and 25°C, and measure the amount of white film formed by crystal violet staining at 24, 48, and 72 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com