Method for strengthening leaching of weathering crust elution-deposited rare earth ore by utilizing additive

A weathering crust leaching type and additive technology is applied in the direction of improving process efficiency, which can solve the problems of troublesome rare earth element separation, impurity element dissolution, limited effect, etc., and achieves reduction of ammonia nitrogen and salt ion pollution, easy raw materials, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

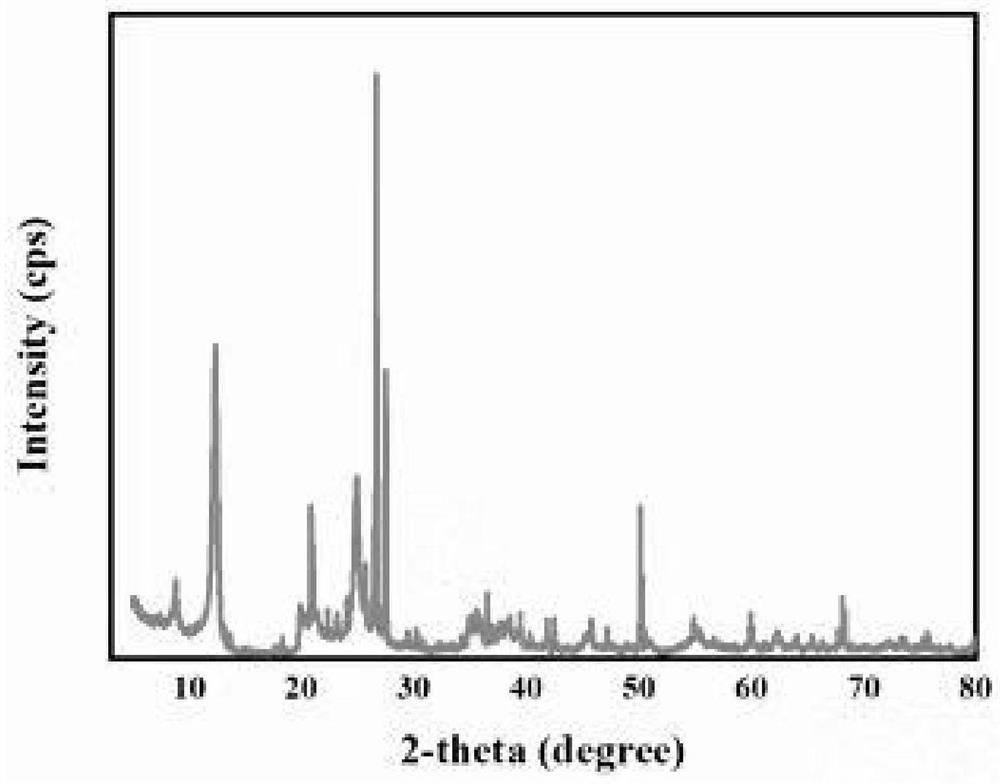

Image

Examples

Embodiment 1

[0023] Take 200g of dried weathering crust elution-type rare earth ore with a rare earth grade of 0.12%, and put the ore sample into a leaching column. Prepare a mixed solution with an ammonium sulfate leaching agent of 0.05mol / L and a malic acid additive concentration of 0.05mol / L, adjust the pH of the mixed solution to 3.0, and then use the mixed solution at a liquid-solid ratio of 7:1 to carry out column leaching of the ore sample The experiment was leached for 5 hours to obtain a rare earth leaching solution. The rare earth leaching solution was tested by an inductively coupled plasma spectrometer and the leaching rate was calculated. The leaching rate of the final rare earth ore sample was 99.5%, and the leaching rate of impurity aluminum was 24.7%.

Embodiment 2

[0025] Take 200g of dried weathering crust elution-type rare earth ore with a rare earth grade of 0.12%, and put the ore sample into a leaching column. Prepare a mixed solution with a magnesium sulfate leaching agent of 0.03mol / L and a citric acid additive concentration of 0.05mol / L, adjust the pH of the mixed solution to 3.0, and then conduct column leaching of the ore sample with the mixed solution at a liquid-solid ratio of 2:1 The experiment was leached for 5 hours to obtain a rare earth leaching solution. The rare earth leaching solution was tested by an inductively coupled plasma spectrometer and the leaching rate was calculated. The leaching rate of rare earth ore samples was 97.5%, and the leaching rate of impurity aluminum was 25.1%.

Embodiment 3

[0027] Take 200g of dried weathering crust elution-type rare earth ore with a rare earth grade of 0.12%, and put the ore sample into a leaching column. Prepare a mixed solution with an ammonium chloride leaching agent of 0.04mol / L and a lactic acid additive concentration of 0.07mol / L, and adjust the pH of the mixed solution to 3.0; then use the mixed solution at a liquid-solid ratio of 1:1 to conduct column leaching of the ore sample The experiment was leached for 5 hours to obtain a rare earth leaching solution. The rare earth leaching solution was tested by an inductively coupled plasma spectrometer and the leaching rate was calculated. The leaching rate of rare earth ore samples was 98.7%, and the leaching rate of impurity aluminum was 23.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com