Preparation method of polyurethane/ferroferric oxide/fibrofelt flexible noise reduction composite material

A technology of ferroferric oxide and composite materials, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems such as lack of sound insulation performance, fixed and unadjustable sound absorption frequency, and achieve coating The effect of simple layer technology and bonding technology, good sound absorption performance and sound insulation performance, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

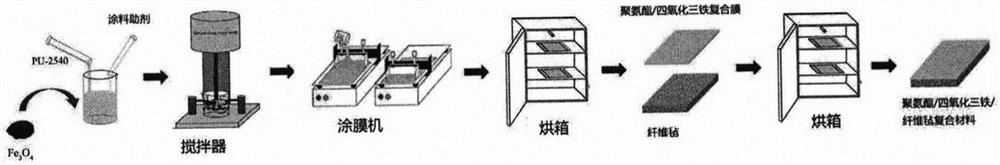

Method used

Image

Examples

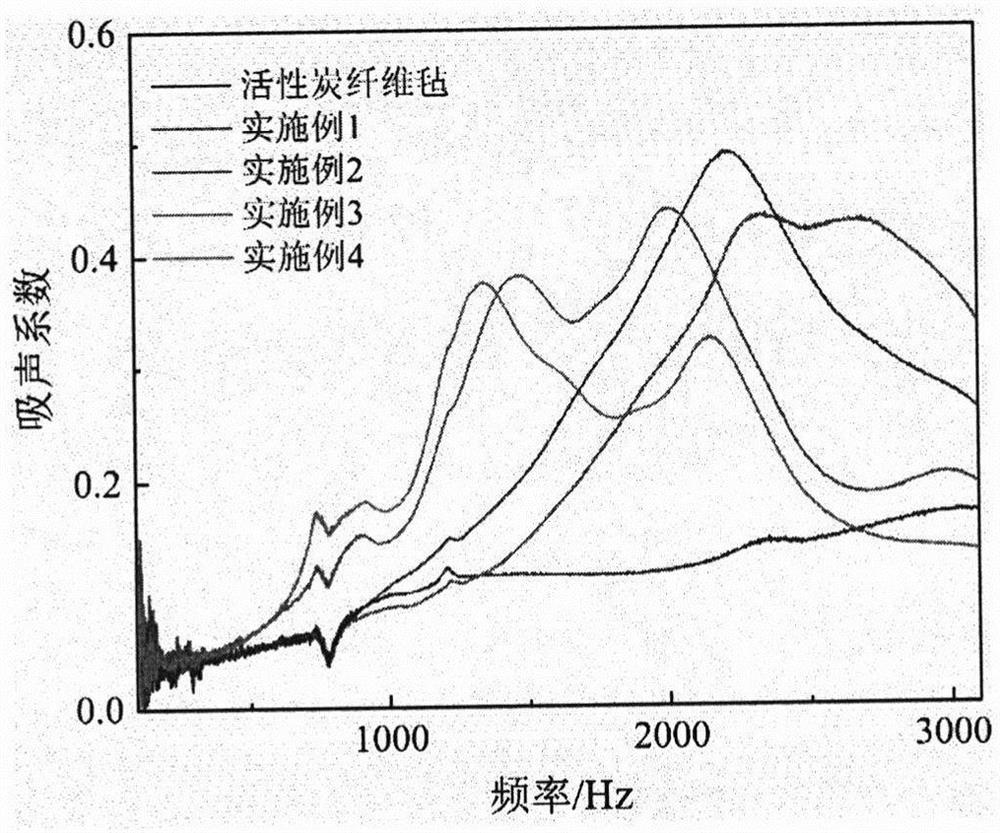

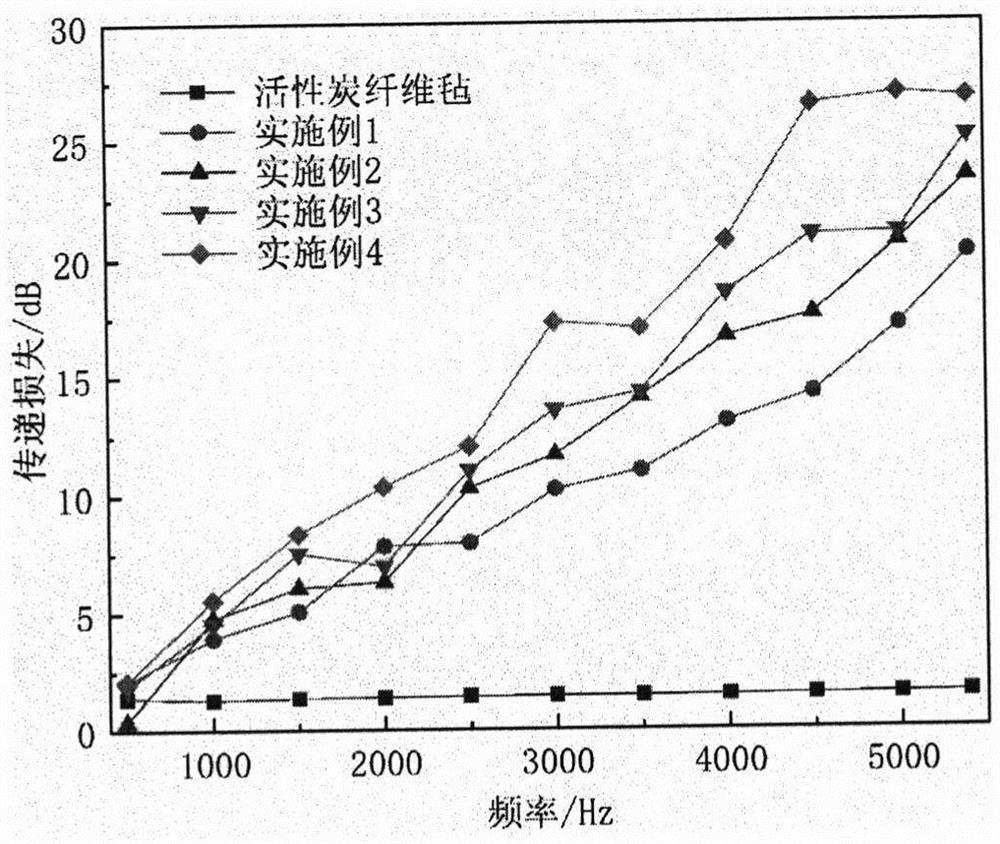

Embodiment 1

[0025] In this embodiment, the base cloth of polyurethane / ferric oxide / fiber felt flexible noise-reducing composite material is selected as activated carbon fiber felt. The paint comprises the following components in parts by weight: waterborne polyurethane: 97.5 parts by weight; defoamer: 0.5 parts by weight; dispersant: 1 part by weight; leveling agent: 1 part by weight.

[0026] Its specific preparation steps are as follows.

[0027] 1) Preparation of paint: a. Weigh 97.5 parts by weight of water-based polyurethane, 0.5 parts by weight of defoamer, 1 part by weight of dispersant and 1 part by weight of leveling agent. b. Clamp and fix the beaker containing polyurethane resin on the stirrer, set the stirrer to run at 1500r / min to stir the resin, add ferric oxide, dispersant, leveling agent and defoamer during the period, until The mixture is mixed well. According to the specific experiment, add a certain amount of thickener into the beaker, then stir at a speed of 1500r / mi...

Embodiment 2

[0031] In this embodiment, the base cloth of polyurethane / ferric oxide / fiber felt flexible noise-reducing composite material is selected as activated carbon fiber felt. The paint comprises the following components in parts by weight: water-based polyurethane: 87.5 parts by weight; ferric oxide: 10 parts by weight; defoamer: 0.5 parts by weight; dispersant: 1 part by weight; leveling agent: 1 part by weight.

[0032] Its specific preparation steps are as follows.

[0033] 1) Preparation of coating: a. Weigh 87.5 parts by weight of water-based polyurethane, 10 parts by weight of ferric oxide, 0.5 parts by weight of defoamer, 1 part by weight of dispersant and 1 part by weight of leveling agent. b. Clamp and fix the beaker containing polyurethane resin on the stirrer, set the stirrer to run at 1500r / min to stir the resin, add ferric oxide, dispersant, leveling agent and defoamer during the period, until The mixture is mixed well. According to the specific experiment, add a cert...

Embodiment 3

[0037] In this embodiment, the base cloth of polyurethane / ferric oxide / fiber felt flexible noise-reducing composite material is selected as activated carbon fiber felt. The paint comprises the following components in parts by weight: water-based polyurethane: 82.5 parts by weight; ferric oxide: 15 parts by weight; defoamer: 0.5 parts by weight; dispersant: 1 part by weight; leveling agent: 1 part by weight.

[0038] Its specific preparation steps are as follows.

[0039]1) Preparation of coating: a. Weigh 82.5 parts by weight of water-based polyurethane, 15 parts by weight of ferric oxide, 0.5 parts by weight of defoamer, 1 part by weight of dispersant and 1 part by weight of leveling agent. b. Clamp and fix the beaker containing polyurethane resin on the stirrer, set the stirrer to run at 1500r / min to stir the resin, add ferric oxide, dispersant, leveling agent and defoamer during the period, until The mixture is mixed well. According to the specific experiment, add a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com