Anti-freezing early-strength alkali-free liquid setting accelerator and preparation method thereof

A technology of early-strength type and quick-setting agent, applied in the field of concrete admixtures, can solve the problems of low early strength and reduced stability of shotcrete, inhibit the hydrolysis of aluminum ions into aluminum hydroxide gel precipitation, promote the formation, improve the effect of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

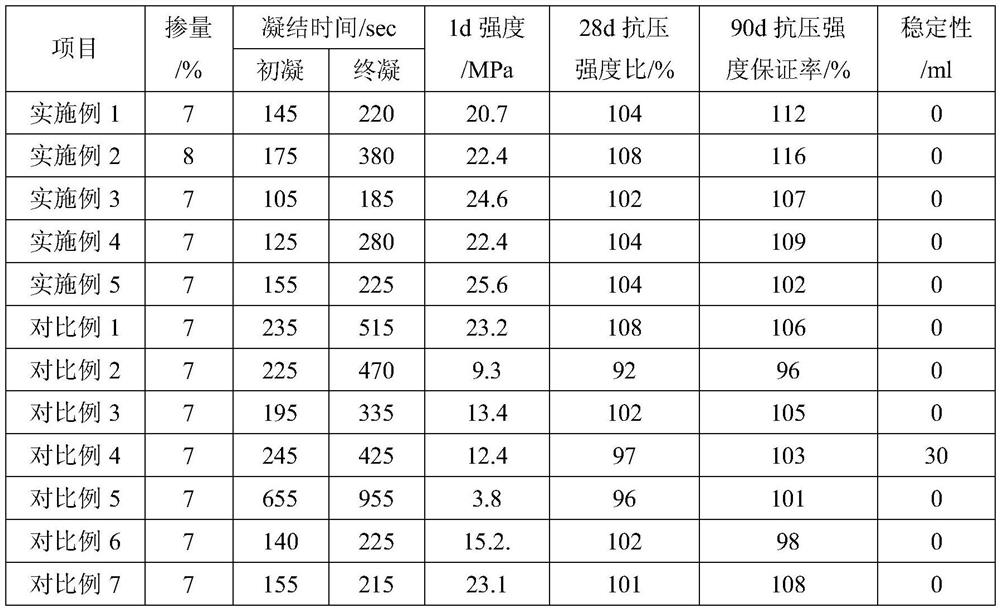

Examples

Embodiment 1

[0041] The preparation of a kind of antifreeze early-strength type non-alkali liquid quick-setting agent comprises the following steps:

[0042] (1) Mix 45g of aluminum sulfate, 5g of magnesium fluorosilicate, 7g of triethanolamine, 3g of aminoethylethanolamine and 38g of water, and keep it warm for 3 hours at a temperature of 80°C; add modified hydrated silicic acid after cooling down to 50°C Magnesium-modified hydrated magnesium silicate and 1g of modified diatomite are mixed evenly to obtain the coagulation-adjusting component;

[0043] (2) Mix 20 g of glutamic acid, 30 g of alanine and 50 g of water, and heat and stir for 0.5 h at a temperature of 50° C. to obtain the required solubilizing component;

[0044](3) Mix 5g of lithium nitrate, 25g of bismuth nitrate, 5g of methanesulfonic acid, 5g of sulfamic acid with 60g of water, and heat and stir for 1 hour at a temperature of 50°C to obtain the required antifreeze early strength component;

[0045] (4) At a temperature of...

Embodiment 2

[0047] The preparation of a kind of antifreeze early-strength type non-alkali liquid quick-setting agent comprises the following steps:

[0048] (1) Mix 35g of aluminum sulfate, 2g of sodium fluorosilicate, 5g of diethanolamine and 57g of water, and keep it warm for 1 hour at a temperature of 70°C; after cooling down to 45°C, add 1g of modified metakaolin, and mix well to get the tune Coagulation component;

[0049] (2) Mix 20 g of aspartic acid, 20 g of alanine and 60 g of water, and heat and stir for 1 hour at a temperature of 45° C. to obtain the required solubilizing component;

[0050] (3) Mix 5 g of lithium nitrate, 15 g of beryllium nitrate, 5 g of benzenesulfonic acid and 75 g of water, and heat and stir for 1 hour at a temperature of 45° C. to obtain the desired antifreeze early strength component;

[0051] (4) At a temperature of 45°C, add 2g of the solubilizing component and 15g of the antifreeze early-strength component to 83g of the coagulation-adjusting componen...

Embodiment 3

[0053] The preparation of a kind of antifreeze early-strength type non-alkali liquid quick-setting agent comprises the following steps:

[0054] (1) Mix 40g of aluminum sulfate, 3g of potassium fluorosilicate, 3g of triisopropanolamine, 5g of diethylenetriamine and 47g of water, and keep it warm for 2 hours at a temperature of 75°C; after cooling down to 45°C, add 2g of modified Non-toxic hydrated magnesium silicate, mixed evenly to obtain the coagulation-adjusting component;

[0055] (2) Mix 15g of glutamic acid, 15g of alanine, 15g of aspartic acid and 55g of water, and heat and stir for 1 hour at a temperature of 45°C to obtain the required solubilizing component;

[0056] (3) Mix 3g of lithium nitrate, 15g of beryllium nitrate, 12g of bismuth nitrate, 5g of methanesulfonic acid, 5g of benzenesulfonic acid with 60g of water, and heat and stir for 1 hour at a temperature of 45°C to obtain the required antifreeze early strength composition Minute;

[0057] (4) At a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com