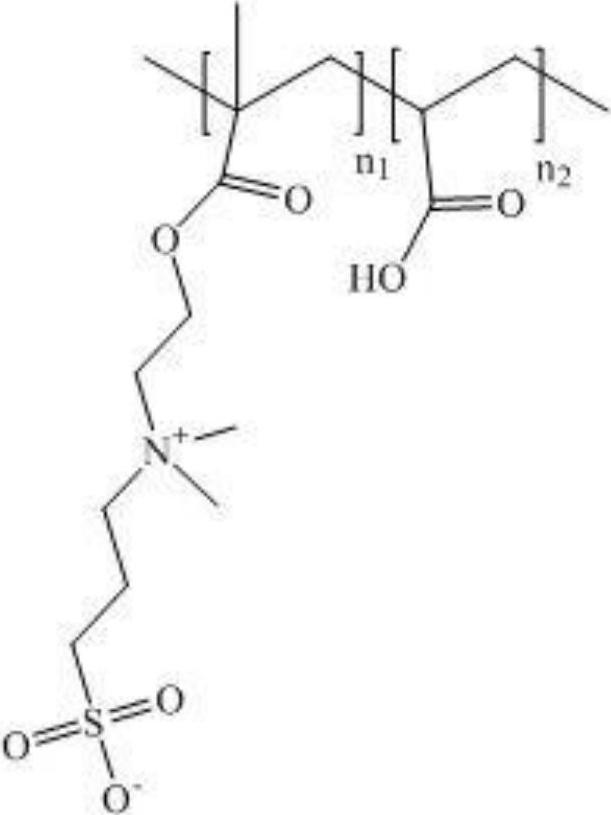

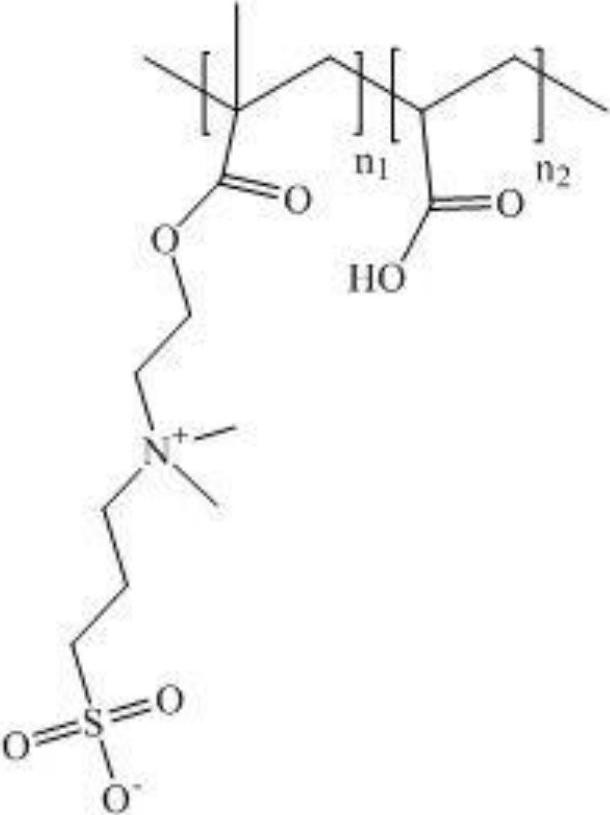

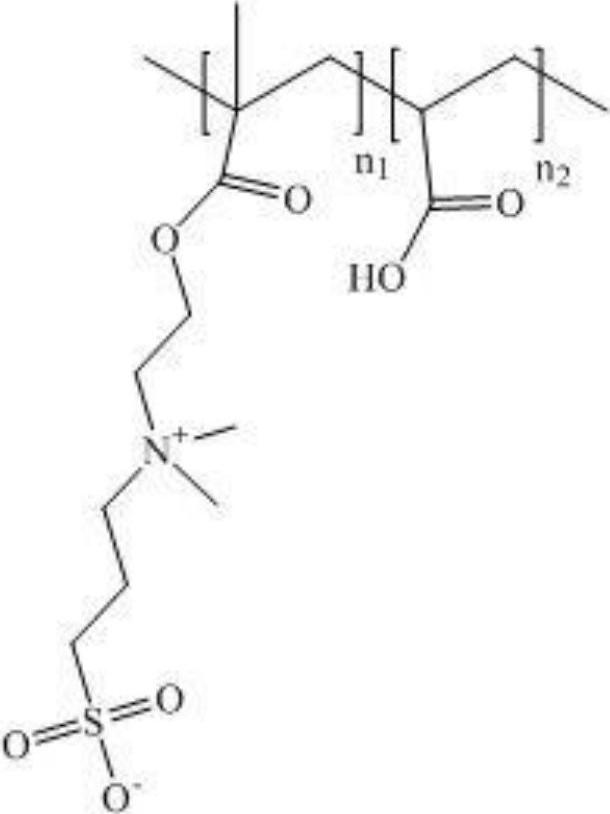

Zwitterionic polymer, and preparation method and application thereof

A zwitterion, polymer technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of high price and limited protein adsorption capacity, achieve simple operation, suitable for large-scale mass production, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of above-mentioned zwitterionic polymer, comprises the following steps:

[0040] 1) Dissolving methacryloylethyl sultaine in water to obtain an aqueous solution of methacryloylethyl sultaine with a concentration of 50-100 mg / mL.

[0041] 2) Stirring, adding acrylic acid to the aqueous solution of methacryloyl ethyl sulfobetaine, and then adding an initiator, raising the temperature to 65-75° C. for 10-12 hours. The molar ratio of methacryloyl ethyl sulfobetaine to acrylic acid is 1: (0.5-2). The mass ratio of the initiator to the methacryloyl ethyl sulfobetaine is 1: (15-20).

[0042] 3) After the reaction is finished, drop the product into absolute ethanol for precipitation at a volume ratio of 1:1-5, and centrifuge for 5-10 minutes at a speed of 3000-5000 r / min, freeze-dry the precipitate for 18-24 hours to the target product.

[0043]The above-mentioned zwitterionic polymers can be used as active ingredients against exogenous stains, bacteri...

Embodiment 1

[0047] A zwitterionic polymer prepared by the following method:

[0048] 1) First weigh 2.79g of white powder of methacryloylethyl sulfobetaine into a single-necked flask, measure 35ml of deionized water into the flask, and stir for 10min at the same time to make methacryloylethyl sulfobetaine Alkali is dissolved in deionized water.

[0049] 2) Weigh 0.36g of acrylic acid (the molar ratio of the two raw materials is 1:0.5) and dissolve it in 10ml of deionized water, and add it into the flask in 1) after completely dissolving.

[0050] 3) Weigh 30 mg of the initiator ammonium persulfate and dissolve it in 5 ml of deionized water, add it into the flask in 1) after completely dissolving, start stirring, heat up to 65 degrees Celsius, and react for 12 hours.

[0051] 4) Drop the mixed liquid obtained after the reaction into a centrifuge tube filled with 80mL of absolute ethanol to precipitate out, put it in a centrifuge and centrifuge at a speed of 3500r / min for 10min, pour off t...

Embodiment 2

[0063] A zwitterionic polymer prepared by the following method:

[0064] 1) First weigh 2.79g of white powder of methacryloylethyl sulfobetaine into a single-necked flask, measure 35ml of deionized water into the flask, and stir for 10min at the same time to make methacryloylethyl sulfobetaine Alkali is dissolved in deionized water.

[0065] Weigh 0.72g of acrylic acid (the molar ratio of the two raw materials is 1:1) and dissolve it in 10ml of deionized water, and add it into the flask in 1) after completely dissolving.

[0066] 3) Weigh 35 mg of the initiator ammonium persulfate and dissolve it in 5 ml of deionized water, add it into the flask in 1) after completely dissolving, start stirring, heat up to 72 degrees Celsius, and react for 10 hours.

[0067] 4) Drop the mixed liquid obtained after the reaction into a centrifuge tube containing 100mL of absolute ethanol to precipitate out, put it in a centrifuge and centrifuge at 4000r / min for 10min, pour off the supernatant, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com