Smelting system and method for reducing magnetic iron generated in copper ore smelting process

A magnetic iron and copper ore technology, applied in chemical instruments and methods, magnetic separation, furnaces, etc., can solve the problem of insufficient time for clarification and separation of slag and matte, the reduction of the effective volume of the precipitation zone in the furnace, and the contact reaction of difficult-to-magnetic iron oxides, etc. problems, to achieve the effect of ensuring the clarification and separation time, reducing the slag temperature and smelting energy consumption, and reducing the copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

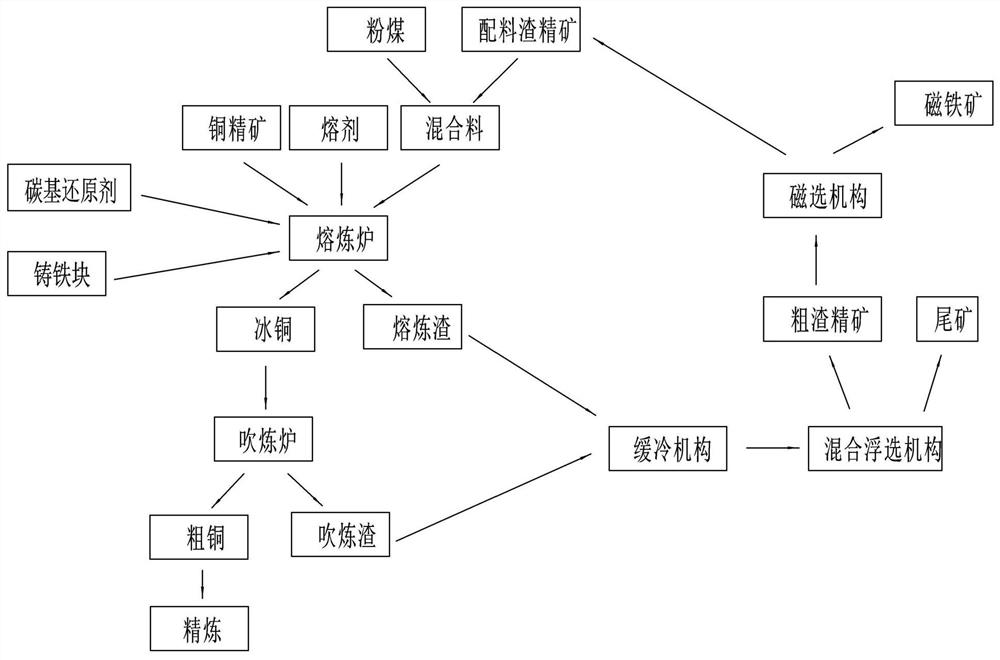

[0032] This embodiment provides a smelting system for reducing the generation of magnetic iron in the copper ore smelting process, including a smelting furnace, a blowing furnace, a slow cooling mechanism, a mixed flotation mechanism and a magnetic separation mechanism connected in sequence, wherein the smelting furnace is provided with There are a matte copper discharge port and a smelting slag discharge port, the matte copper discharge port is connected with the feeding port of the blowing furnace, and the blowing furnace is provided with a crude copper discharge port and a blowing slag discharge port, and the smelting slag discharge port is The feed port and blowing slag outlet are all connected to the slow cooling mechanism; the smelting slag and its blowing slag are sequentially processed by the slow cooling mechanism, the mixed flotation mechanism and its magnetic separation mechanism to obtain the batching slag concentrate; the copper ore smelting system There is also a ...

Embodiment 2

[0038]The present embodiment provides a method for reducing the production of magnetic iron in the copper ore smelting process, comprising the following steps:

[0039] 1) Put batching slag concentrate and pulverized coal into the mixing cylinder, and stir evenly to form a mixture;

[0040] 2) Send the mixture, copper concentrate and its flux into the bottom blowing smelting furnace. The pulverized coal has reducing properties and can react with magnetic iron. When the pulverized coal is excessive, the reaction 4C+Fe will occur 3 o 4 =3Fe+4CO, when the magnetic iron is excessive, the reaction Fe 3 o 4 +2C=3Fe+2CO 2 , and usually the magnetic iron is excessive, the second reaction occurs to reduce the content of magnetic iron;

[0041] 3) Bubble oxygen and carbon-based reducing agent into the bottom-blown smelting furnace for smelting, and react Fe 3 o 4 +2C=3Fe+2CO 2 , and put cast iron blocks into the bottom blowing smelting furnace through the smoke outlet, and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com